Carbon fiber multifilament spline reinforcing method and device thereof

A reinforcement device and carbon fiber technology, which is applied in the field of carbon fiber detection devices, can solve problems such as inaccurate test results and unsatisfactory carbon fiber multifilament reinforcement effects, and achieve the effects of avoiding difficult cleaning, improving curing quality and efficiency, and reducing personnel costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

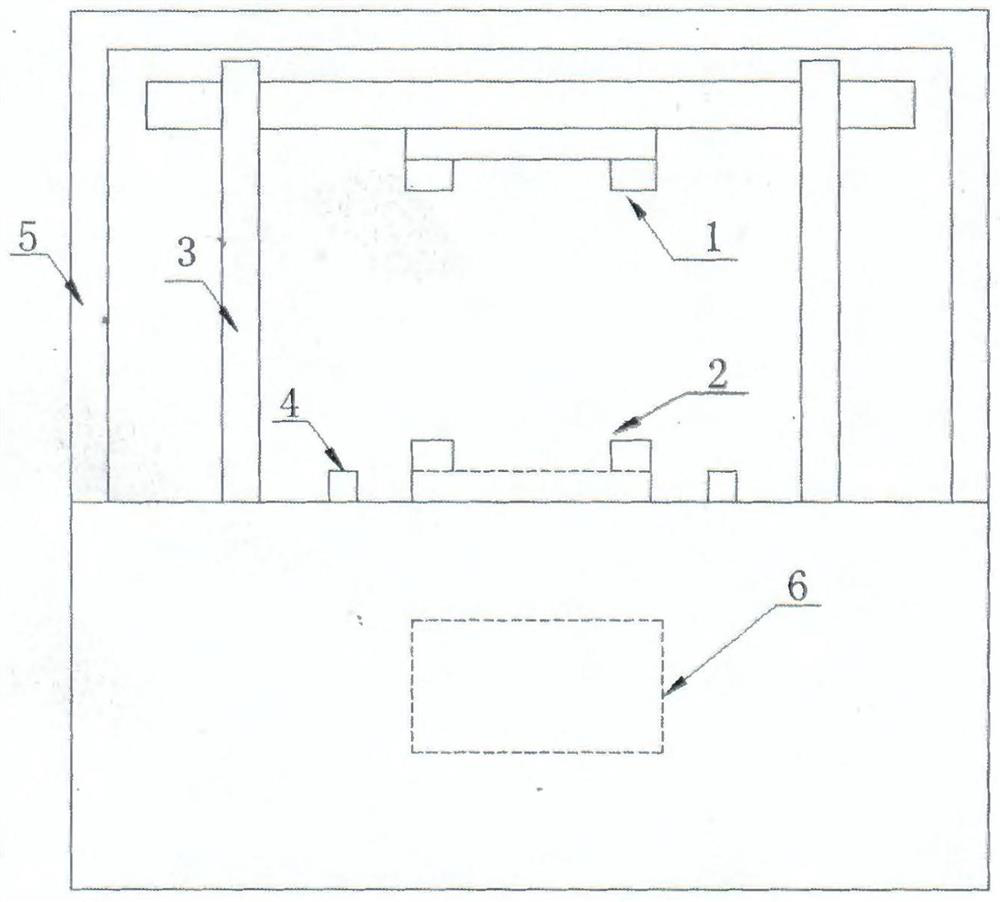

[0036] Take the 12k carbon fiber spline as an example:

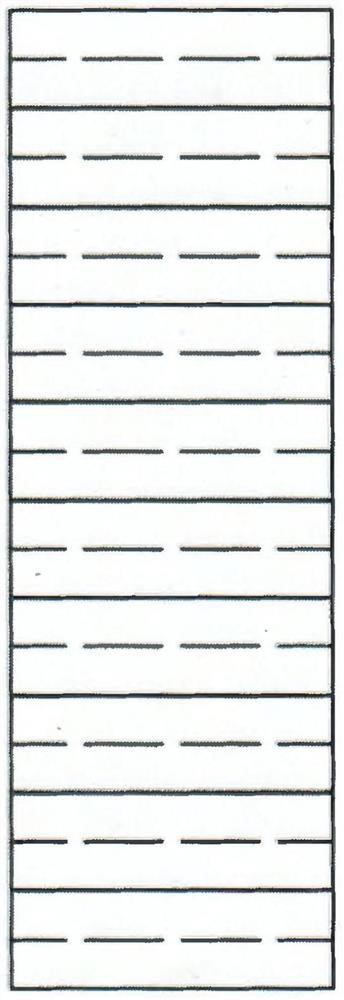

[0037] 1. Set the width of the reinforcing sheet (that is, the distance between the dotted lines) to 15mm for kraft paper;

[0038] 2. Through the control system, the lower pressing plate of the strengthening device is ejected as a strengthened working platform;

[0039] 3. Place kraft paper on the left and right sides of the lower platen, the width is equal to the lower platen, and the edge is flush with the lower platen;

[0040] 4. Place the multifilament spline to be reinforced at the dotted line of the kraft paper;

[0041] 5. Take the reinforced resin with a syringe, and inject 1.0g of resin evenly at a position about 5mm away from the edge of the kraft paper from the multifilament spline vertically above the kraft paper;

[0042] 6. Cover the left and right sides of the lower platen with a layer of kraft paper, aligning with the edge of the bottom kraft paper;

[0043] 7. Through the control system, the lower p...

Embodiment 2

[0060] Take the 48k carbon fiber spline as an example:

[0061] 1. Set the width of the reinforcing sheet (that is, the distance between the dotted lines) to 20mm for kraft paper;

[0062] 2. Through the control system, the lower pressing plate of the strengthening device is ejected as a strengthened working platform;

[0063] 3. Place kraft paper on the left and right sides of the lower platen, the width is equal to the lower platen, and the edge is flush with the lower platen;

[0064] 4. Place the multifilament spline to be reinforced at the dotted line of the kraft paper;

[0065] 5. Take the reinforced resin with a syringe, and inject 1.6g of resin evenly at a position about 5mm away from the edge of the kraft paper from the multifilament spline on the kraft paper vertically above;

[0066] 6. Cover the left and right sides of the lower platen with a layer of kraft paper, aligning with the edge of the bottom kraft paper;

[0067] 7. In the control system of the strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com