Method for correcting tilt error of workpiece table and photoetching device

A technology of tilt error and workpiece table, which is applied in the exposure device of photolithography process, microlithography exposure equipment, optics, etc., can solve the problem of low measurement accuracy, achieve high calibration accuracy, reduce mechanical error, and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

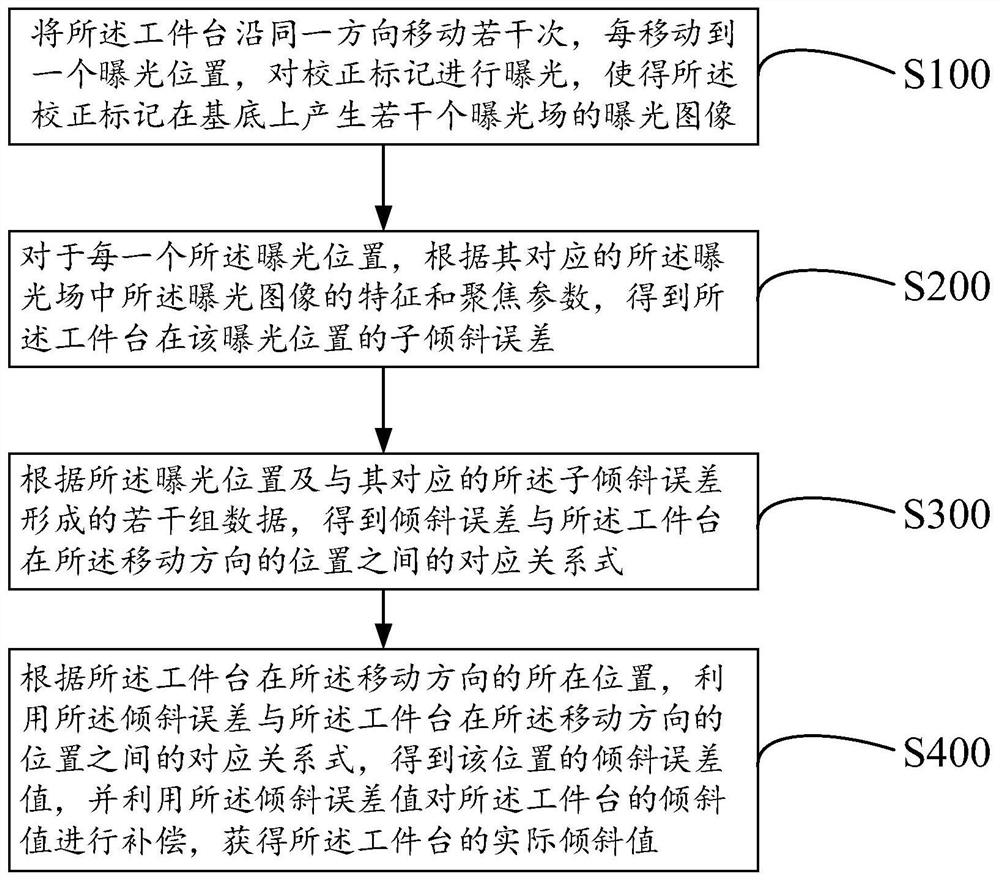

[0080] This embodiment provides a method for correcting the tilt error of the workpiece table, which is used for correcting the tilt error when the workpiece table moves in the Y direction. In this embodiment, as attached Figure 4 As shown, it is a schematic diagram of the calibration marks provided on the mask in this embodiment. It can be seen from the figure that the sub-marks 201 of the calibration marks are distributed in N rows×M columns, where N≧2. The row distribution of the sub-marks 201 is consistent with the X direction, and the column distribution of the sub-marks 201 is consistent with the Y direction. For ease of description, in this embodiment, N=3 is taken as an example for description, which is obviously not a limitation of the present invention.

[0081] A method for correcting the inclination error of the workpiece table provided in this embodiment includes the following four steps of S100, S200, S300 and S400.

[0082] S100: Move the workpiece table seve...

Embodiment 2

[0094] The method for correcting the inclination error of the workpiece table provided in this embodiment is used for correcting the inclination error of the workpiece table when it moves in the X direction. In this embodiment, as attached Figure 6 As shown, it is a schematic diagram of the calibration marks provided on the mask in this embodiment. It can be seen from the figure that the sub-marks 202 of the calibration marks are distributed in N rows×M columns, where M≥2. The row distribution of the sub-marks 202 is consistent with the X direction, and the column distribution of the sub-marks 202 is consistent with the Y direction. For the convenience of description, in this embodiment, M=3 (in this embodiment, there are 3 columns of submarks) is taken as an example for illustration, obviously, this is not a limitation of the present invention.

[0095] A method for correcting the inclination error of the workpiece table provided by this implementation includes the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com