Method for evaluating quality of quick food detection result

An evaluation method and quality technology, applied in the field of quality evaluation of food rapid inspection results, can solve the problems of low value of rapid inspection data, wide inspection coverage, and lack of utilization, so as to reduce the workload of re-inspection and have broad application prospects. , improve the effectiveness of supervision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0133] Embodiment 1 establishes the EI model of rapid inspection work quality evaluation

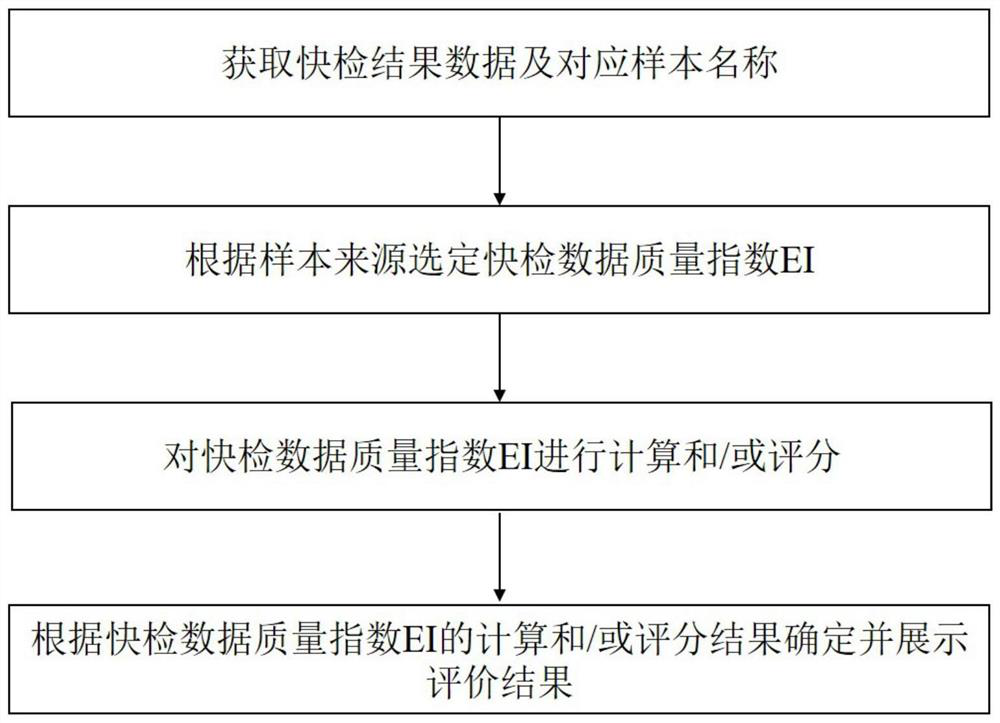

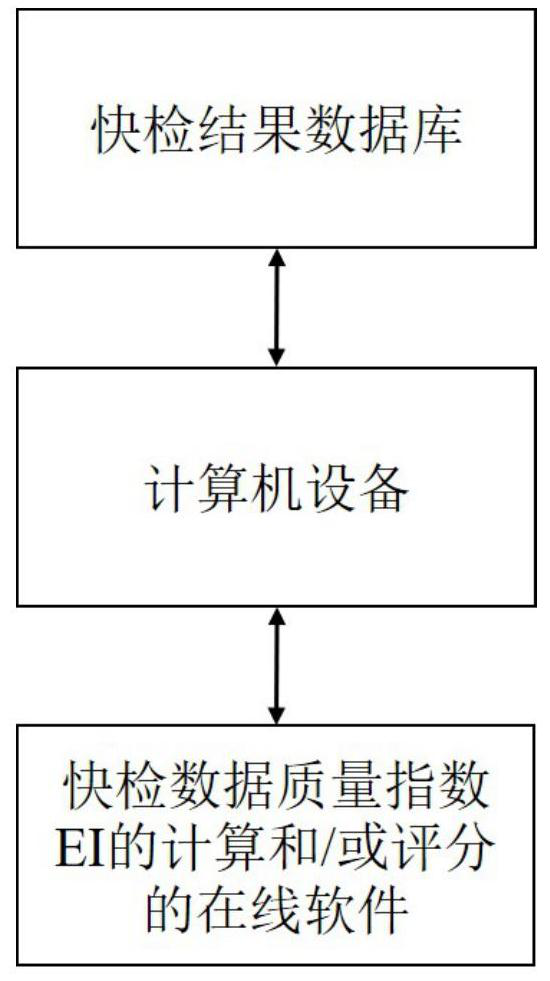

[0134] Collect and clean the quick test data, create a series of indicators reflecting the quality of the quick test data, and propose a data quality level evaluation model, so as to build the entire quality evaluation system of the quick test result data.

[0135] Through in-depth mining of the quick inspection data, relevant factors that may reflect the quality of the quick inspection work are screened out, including but not limited to the completion of each variety of testing, the frequency of random inspection of each variety, the coverage ratio of sampling varieties, the coverage ratio of inspection items, and the sampling file There are 9 indexes, including mouth coverage ratio, abnormal value ratio of inspection data, matching ratio of varieties and items, unqualified batch / unqualified rate statistics, and unqualified follow-up inspection. The quality factors proposed as quick insp...

Embodiment 2

[0155] Example 2 Establishment of key screening list for quick inspection

[0156] From the unqualified data of the rapid inspection displayed by EI8 in the data quality evaluation system of the quick inspection results, varieties with a high rate of problem discovery can be screened out, thereby establishing a key screening list of pesticide and veterinary drug residues, which provides key screening items for the annual quick inspection work and Variety provides guidance.

[0157] Based on the data in 2019, the total number of testing batches, the number of unqualified batches, and the unqualified rate of different varieties and items are statistically summarized, and appropriate screening conditions are systematically set according to the detection status of each item, and finally the key screening list for 2020 is generated. Look up the list, as shown in Table 5.

[0158] Table 5 Key screening list for 2020

[0159]

[0160]

[0161]

[0162]

[0163]

Embodiment 3

[0164] Example 3 Carry out targeted screening of farmers' markets

[0165] In the rapid inspection big data EI model selected and established from the quick inspection result data quality evaluation system, in 2019, 38 farmers' markets were selected for on-site evaluation through the EI model, including 16 low-risk markets, 17 medium-risk markets, and high-risk markets. There are 5 markets, accounting for 18.54% (38 / 205) of the total number of on-site evaluation markets that year.

[0166] Among the 5 high-risk markets, 3 failed to pass the field evaluation after on-site evaluation, indicating that the target hit rate using the EI model can be as high as 60% (3 / 5). The large batch of abnormal data in the data reporting system also reflects the poor completion of quick inspection work such as data abnormal reporting in the upgrading and transformation market, which greatly increases the efficiency of screening unqualified markets. Among the other 167 farmers' markets evaluated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com