Railway vehicle running gear welding seam detection method and system

A detection method and technology for rail vehicles, applied in computer parts, image data processing, instruments, etc., can solve problems such as low accuracy, and achieve the effects of improving accuracy, improving detection efficiency, and improving image feature recognition capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

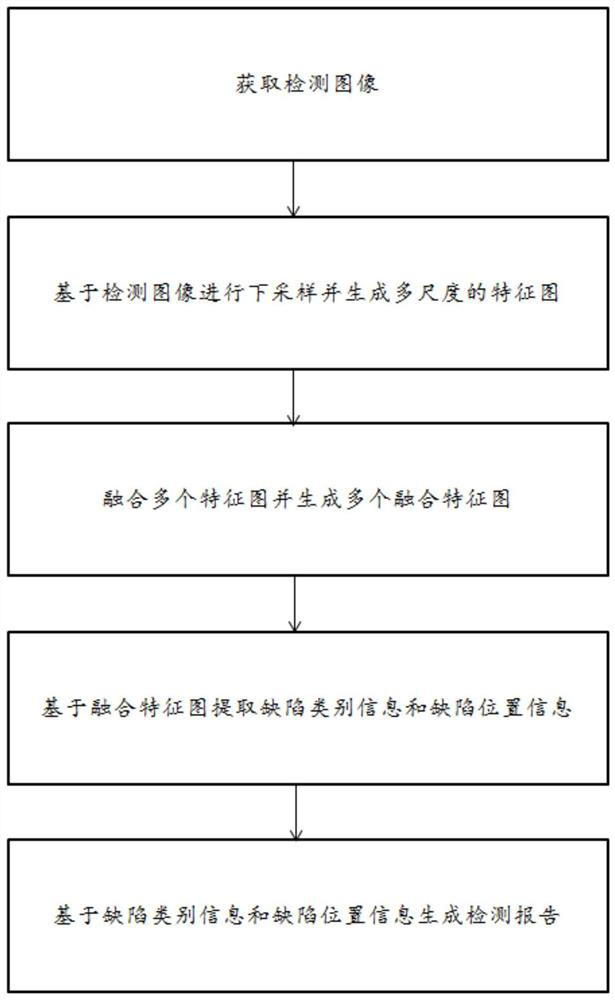

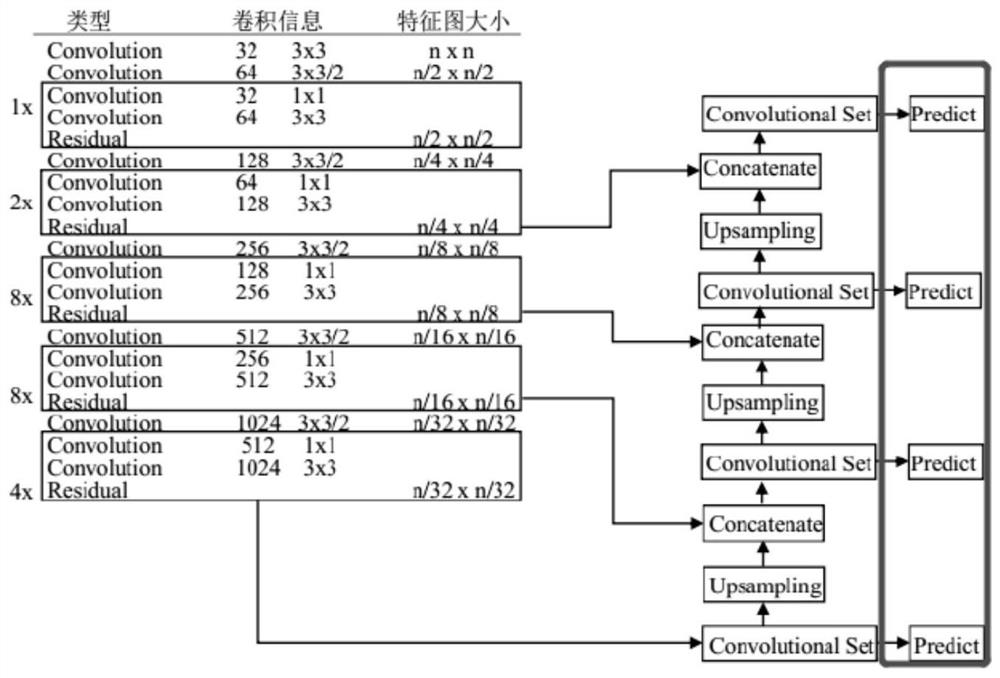

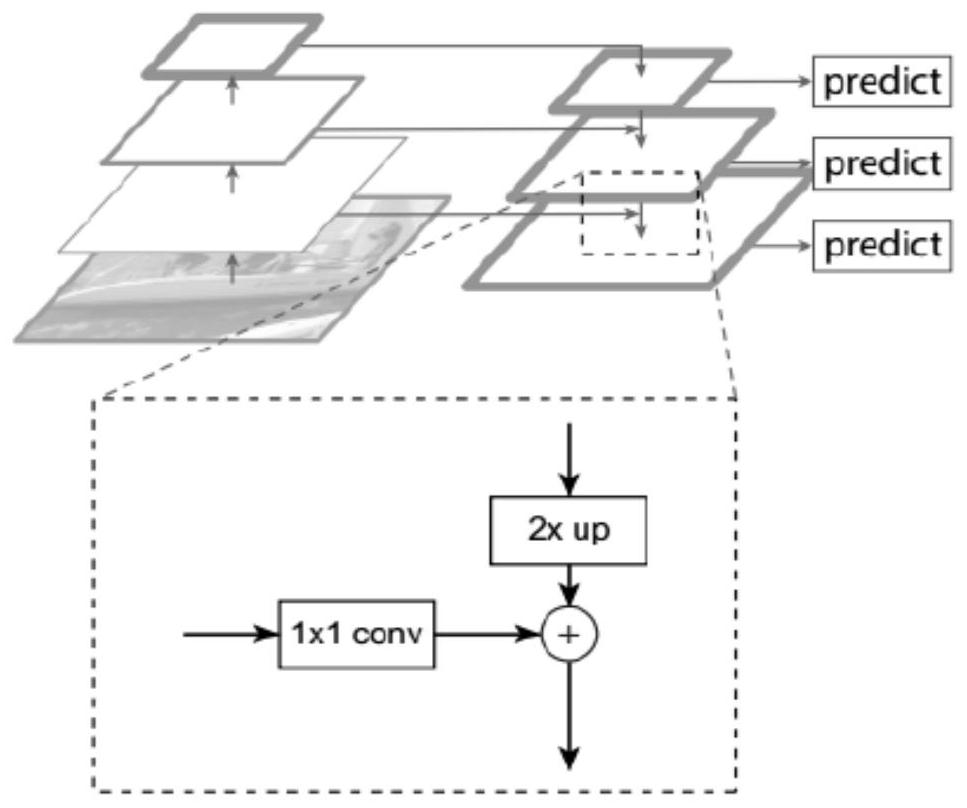

[0021] Such as figure 1 As shown, a detection method of a rail vehicle running part weld, comprising: obtaining a detection image; performing down-sampling based on the detection image and generating a multi-scale feature map; fusing multiple feature maps and generating multiple fusion features drawing; extracting defect category information and defect location information based on the fusion feature map; generating a detection report based on the defect category information and the defect location information. Wherein, acquiring the detection image includes: performing eddy current non-destructive testing on the running part weld structure; generating the detection image composed of surface C-scan data based on the detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com