A heating system with a four-way reversing valve and a three-way reversing valve

A three-way reversing valve, four-way reversing valve technology, applied in heating systems, multi-way valves, central heating components, etc., can solve the problem of increasing system pipeline connections and valves, increasing investment costs, and increasing system complexity and other problems to achieve the effect of reducing system structure and cost, reducing the use of valves and pipelines, and realizing complementary utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

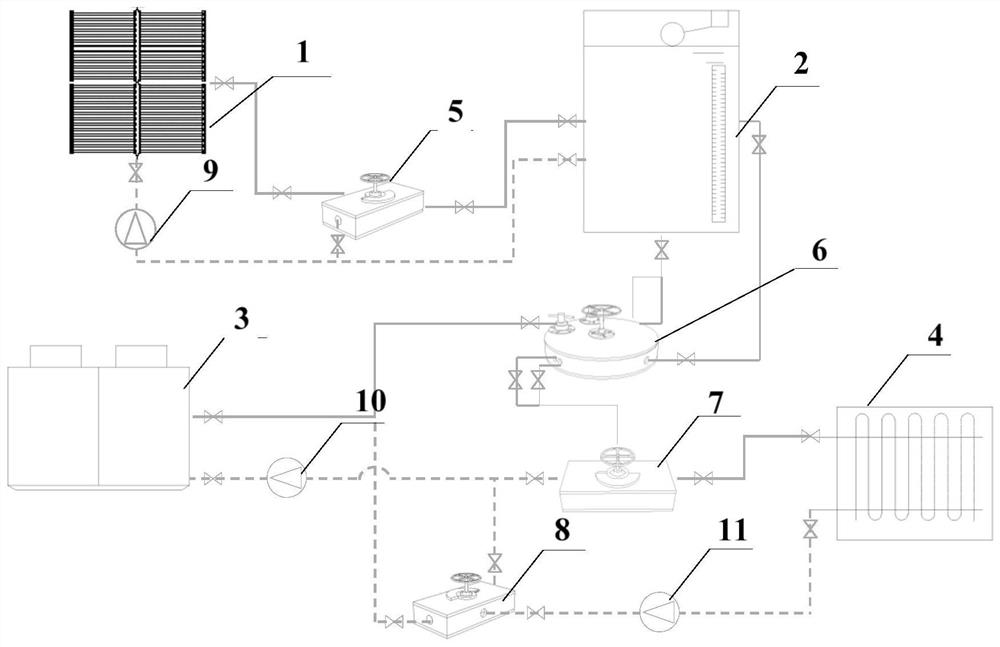

[0037] Such as Figure 1-Figure 7 As shown, a heating system with a four-way reversing valve and a three-way reversing valve includes a solar heat collection system, an air source heat pump system, a hot water storage tank 2 and a terminal cooling device 4. The solar heat collection system includes Solar heat collector 1, the first three-way reversing valve 5 and circulating water pump B19, the first three-way reversing valve 5 includes a water inlet main pipe and 2 water outlet branch pipes, the outlet of the solar heat collector 1 The water inlet is connected to the water inlet main pipe of the first three-way reversing valve 5 through the water inlet pipeline, and a water outlet branch pipe of the first three-way reversing valve 5 is connected to the first water inlet pipe of the hot water storage tank 2 through the water inlet pipeline. The outlet pipe of the hot water storage tank 2 is connected to the solar collector 1 through the return water pipeline, and the circulati...

Embodiment 2

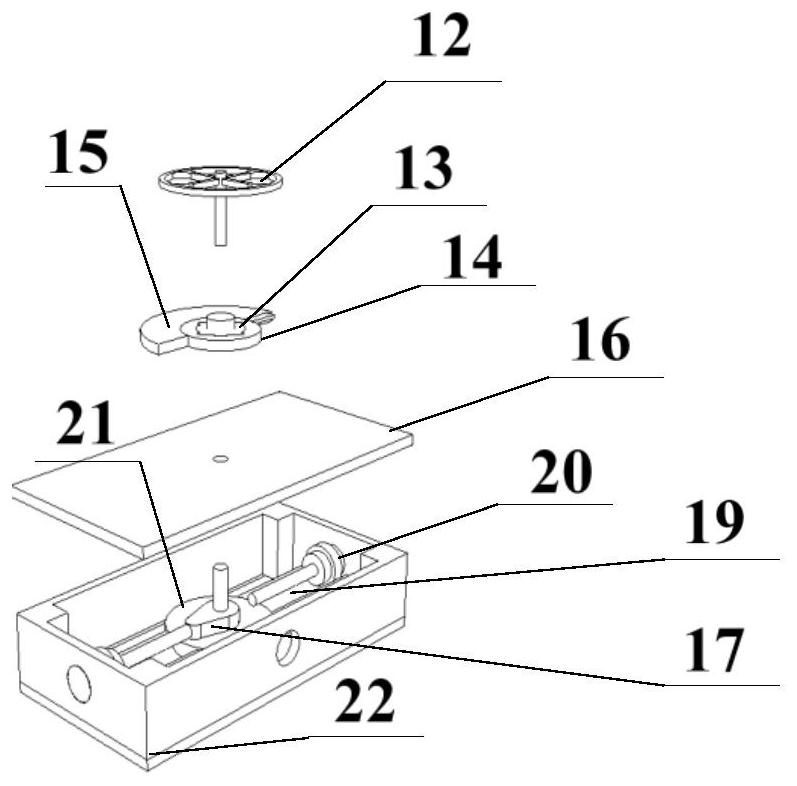

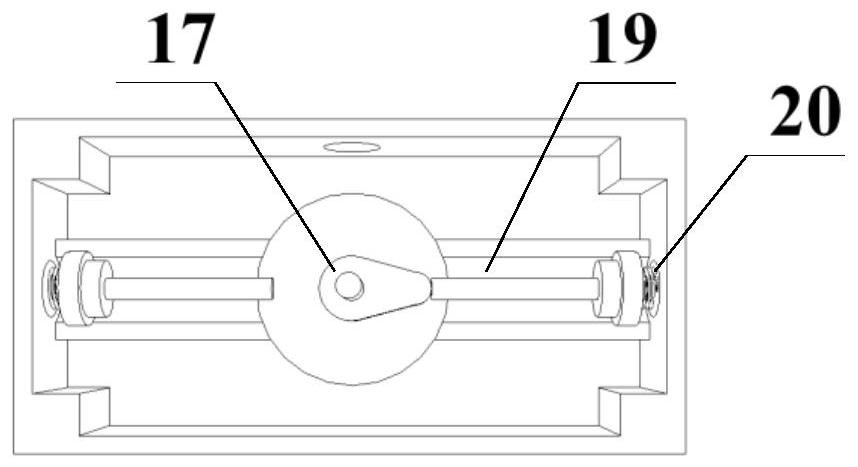

[0054] Such as Figure 1-Figure 7As shown, this embodiment is based on Embodiment 1, and the first three-way reversing valve 5 or the second three-way reversing valve 7 or the third three-way reversing valve 8 also includes an extended arm shaft 13, a swing arm 14, Draw-in groove 15, described swing arm shaft 13 and swing arm 14 are all fixed on the rotating shaft that is connected with rotary handle 12, and described swing arm 14 is arranged at the bottom of swing arm shaft 13, and swing arm 14 and swing arm shaft 13 are circular Ring structure, the card slot 15 is arranged on the top of the valve cover 16, which is a semi-circular structure, the outer diameter of the swing arm 14 is consistent with the inner diameter of the card slot 15, and the outer wall of the extended arm shaft 13 is evenly arranged with four When the swing arm 14 is fully rotated to the point where the two projections are parallel to the straight line of the slot 15, the cam structure 17 squeezes the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com