Non-contact micro-current measurement system based on Rogowski coil

A Rogowski coil and non-contact technology, which is applied in the field of non-contact micro current measurement system, can solve problems such as being susceptible to external interference, small voltage signal, difficult to measure accurately, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

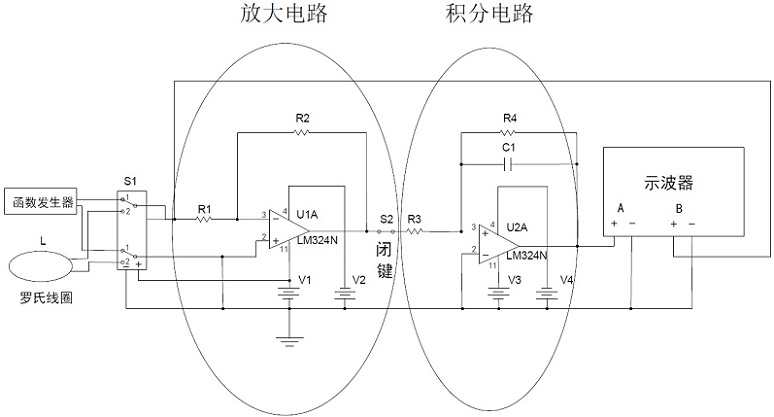

[0092] Such as figure 1 As shown, the circuit simulation software is used for simulation analysis, and the analog function signal generator is used to simulate the output voltage signal of the Rogowski coil (ie figure 1 Turn on the function generator with switch S1); set the frequency of the function signal generator in the simulation software as f =1000 Hz, the amplitude parameter is A =0.2 mV, close the switches S1 and S2, and start the simulation;

[0093] Such as Figure 5 As shown, open the analog oscilloscope of the simulation software, and obtain the simulation results on the analog oscilloscope.

[0094] Among them, the display parameters of the analog oscilloscope are set as follows: in the horizontal direction, each large division represents 0.5 ms; in the vertical direction, each large division represents 0.2 mV; from Figure 5 It can be seen that the simulation result is a sinusoid with an amplitude of 0.2 mV, a frequency of 1000 Hz, and a DC component of 0; ...

Embodiment 2

[0096] To set up the measurement system, use the AC voltage output by a function signal generator, connect a 50 Ω load resistor in series, and pass the closed loop wire through the Rogowski coil in a non-contact manner. By adjusting the output voltage of the function signal generator, the magnitude of the current passing through the Rogowski coil can be changed.

[0097] When the current passing through the Rogowski coil is set to be 0.2 mA, that is, when the output voltage of the function signal generator is 0.01 V, it is measured from the oscilloscope. One large division is 0.2 mV. By recording, a sinusoidal signal with an amplitude of 0.22 mV and a frequency of 1000 Hz was obtained on the oscilloscope; compared with the input current amplitude of 0.2 mA, it can be proved that the designed circuit can recover the original output current amplitude signal.

[0098] In order to further illustrate the applicability of the designed circuit, without changing the value of the load...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coil turns | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com