Metal shell lead structure capable of reducing glass cracks

A technology of metal leads and metal shells, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as glass insulator cracks, circuit sealing failure, etc., to achieve the effect of improving insulation effect, facilitating production and processing, and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

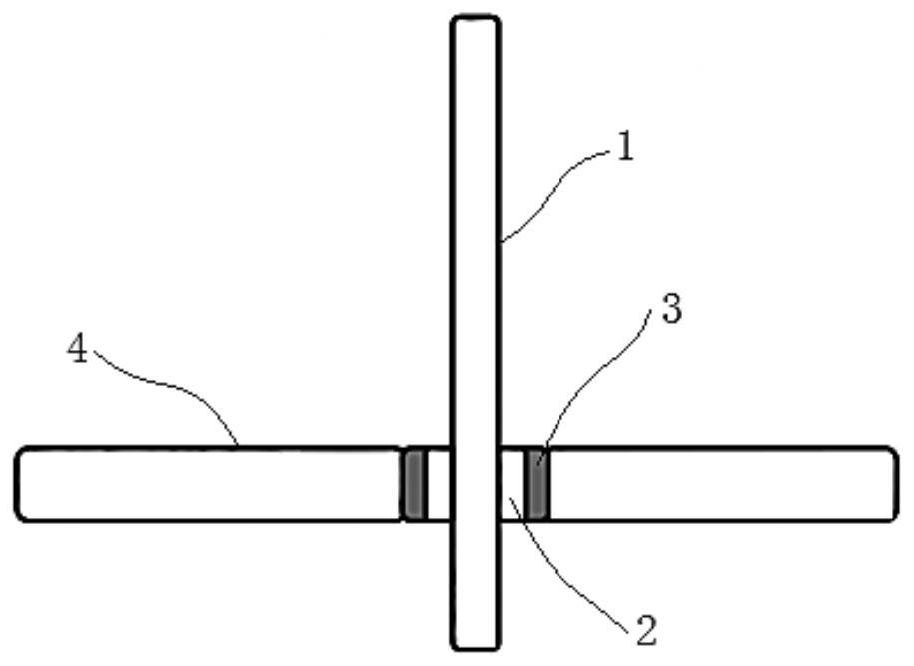

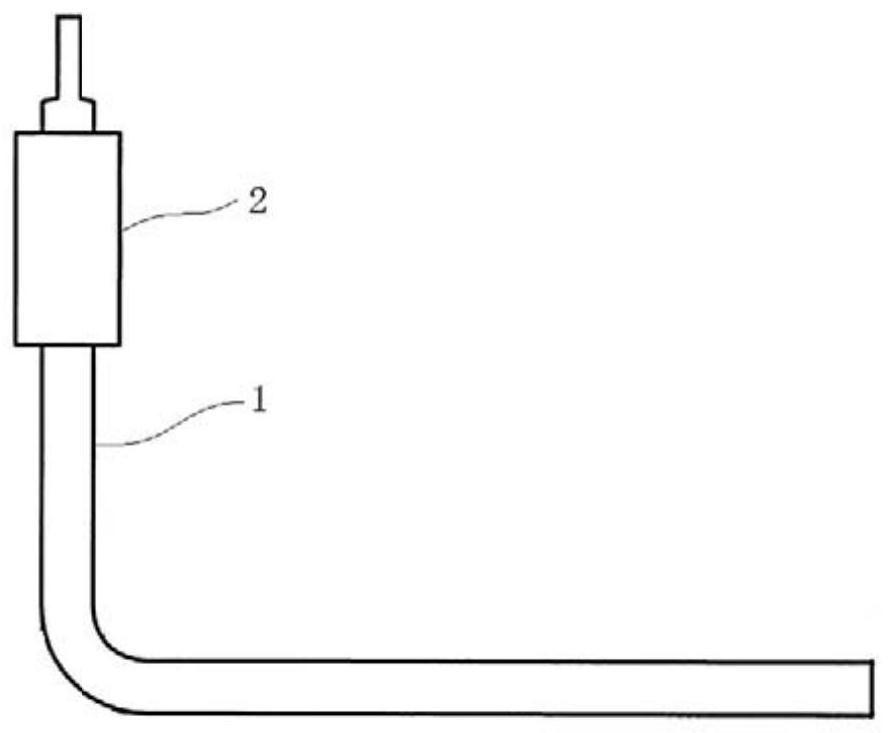

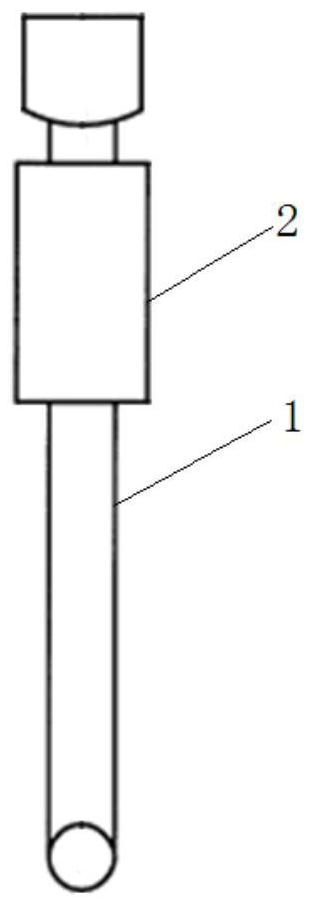

Embodiment 1

[0044] The diameter of the metal lead 1 is 0.38mm, which is a flexible lead, and the diameter of the force-bearing structure 2 is 0.8mm. The metal lead wire 1 is also easily deformed after being subjected to external force, but after deformation, the stress point is shifted to the part where the thickness of the metal changes, and the glass insulator avoids stress, and no longer introduces glass cracks and sealing air leakage problems.

Embodiment 2

[0046] The diameter of the metal lead 1 is 0.45mm, which is a flexible lead, and the diameter of the force-bearing structure 2 is 1.0mm. The metal lead wire 1 is also easily deformed after being subjected to external force, but after deformation, the stress point is shifted to the part where the thickness of the metal changes, and the glass insulator avoids stress, and no longer introduces glass cracks and seal air leakage problems.

Embodiment 3

[0048] The diameter of the metal lead 1 is 0.50mm, which is a flexible lead, and the diameter of the force-bearing structure 2 is 1.0mm. The metal lead wire 1 is also easily deformed after being subjected to external force, but after deformation, the stress point is shifted to the part where the thickness of the metal changes, and the glass insulator avoids stress, and no longer introduces glass cracks and seal air leakage problems.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com