Power failure holding circuit and control method

A technology of power-down retention and control methods, applied to electrical components, conversion equipment without intermediate conversion to AC, output power conversion devices, etc., can solve the problem of slow dynamic response of mode switching, fast switching response speed, narrow application range, etc. problem, to achieve the effect of fast switching response, wide application range and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

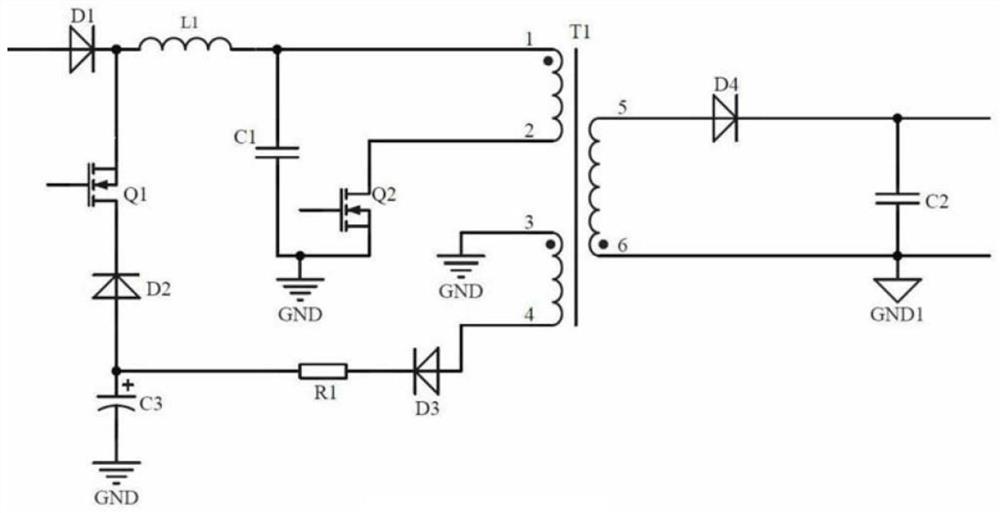

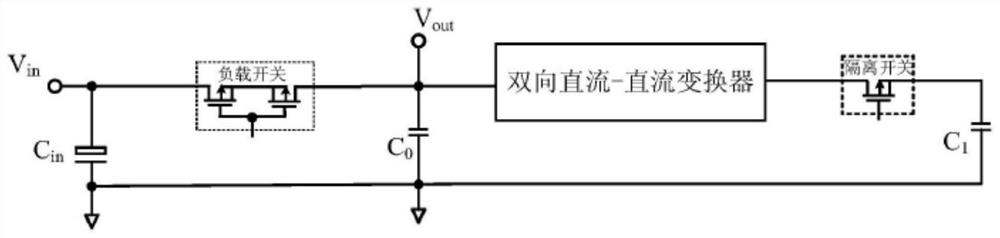

[0032] Please refer to Figure 4 , the power-fail holding circuit of this embodiment is used to connect between the output terminal of the power supply of the previous stage and the input terminal of the switching power supply of the subsequent stage, including: a main power circuit and a controller.

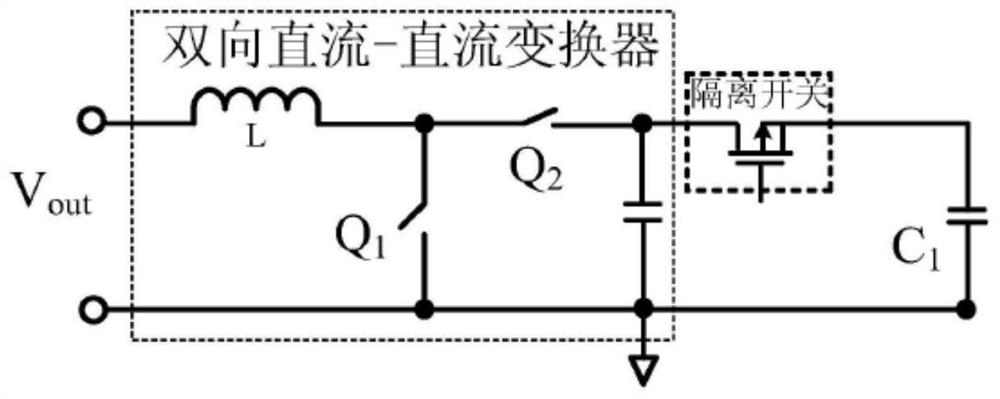

[0033] The main power circuit includes switch K, filter capacitor C L , Energy storage capacitor C H , and connected between the switch K and the energy storage capacitor C H Between the bidirectional DC converter, the output terminal Vo is drawn from the connection point of the switch K and the bidirectional converter, and the input terminal Vin is drawn from the other end of the switch K, and the filter capacitor C L It is connected between the output terminal Vo and the reference ground terminal GND. The bidirectional DC converter includes an inductor L, a switch tube S1, a switch tube S2, a diode D1 and a diode D2. The bidirectional DC converter is controlled by the cont...

no. 2 example

[0060] Please refer to Figure 7 , the power-down holding circuit of the present embodiment is basically the same as that of the first embodiment, both including the main power circuit and the controller; comparison Figure 4 and Figure 7 It can be seen that the main difference between this embodiment and the first embodiment is that the second embodiment changes the switch K at the input end to a controllable switch S3, and other connections and working principles are the same, and will not be repeated here. However, the control method of the holdover circuit in this embodiment is the same as that in the first embodiment.

[0061] Compared with the first embodiment, the advantage of this embodiment is that when it is applied to medium and high power power-failure retention, the use of a controllable switch S3 with a small on-resistance can further reduce losses and improve system efficiency.

[0062] That is to say, when the holdover circuit of the present invention is app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com