Crude aniline purification device for aniline production

A purification device and crude aniline technology, applied in amino compound purification/separation, organic chemistry, chemical instruments and methods, etc., can solve problems such as impurity of aniline components, aniline thermal decomposition, etc., to avoid impurity of aniline components, avoid aniline Thermal decomposition, the effect of avoiding excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

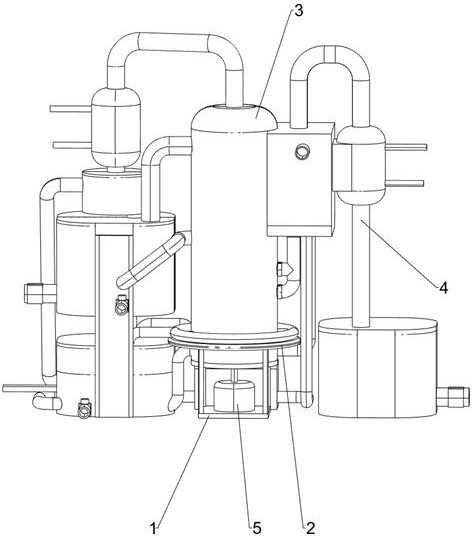

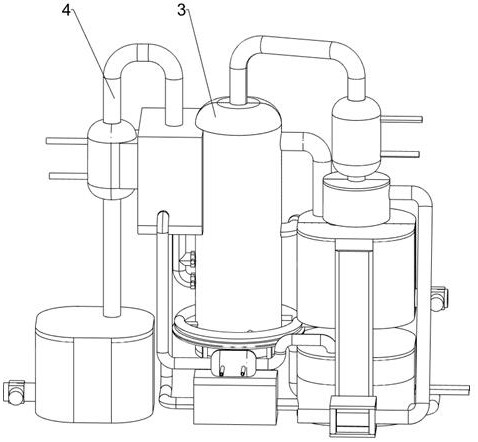

[0031] A crude aniline purification device for aniline production, such as figure 1 and figure 2 As shown, it includes a mounting frame 1, a mounting plate 2, an outer shell 3, a dehydration assembly 4 and a purification assembly 5. The top of the mounting frame 1 is provided with a mounting plate 2, and the inside of the mounting plate 2 is fixed with an outer shell 3. The mounting frame One side of 1 is provided with a dehydration assembly 4, and the dehydration assembly 4 communicates with the outer casing 3, and a purification assembly 5 is arranged in the installation frame 1, and the purification assembly 5 communicates with the dehydration assembly 4.

[0032] When using this equipment, the user discharges the crude aniline into the dehydration assembly 4 through the external equipment, and the crude aniline in the dehydration assembly 4 then flows downward into the heating part, and at the same time, the user starts the heating part to work, and the heating part works...

Embodiment 2

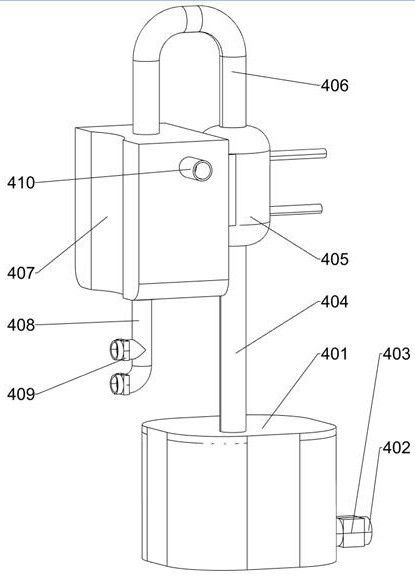

[0034] On the basis of Example 1, such as Figure 3-12 As shown, the dehydration assembly 4 includes a water tank 401, an output pipe 402, a first solenoid valve 403, a first water inlet pipe 404, a first condenser 405, a first air inlet pipe 406, a dehydration tank 407, a first water outlet pipe 408, The second solenoid valve 409, the second water inlet pipe 410, the horizontal plate 412, the heating box 414, the support block 415, the third water inlet pipe 416, the temperature regulator 417 and the first air outlet pipe 418, the water tank 401 is located on the left side of the installation frame 1 side, the left wall of the water tank 401 is embedded with an output pipe 402, the output pipe 402 is provided with a first solenoid valve 403, the top of the water tank 401 is provided with a first water inlet pipe 404, and the upper part of the first water inlet pipe 404 is provided with a first Condenser 405, first air inlet pipe 406 is arranged on the top of first condenser 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com