Improved silica stain test structures and methods therefor

A technology for testing structures and silica, which is applied in the direction of optical testing flaws/defects, semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, etc. It can solve the inconvenience of process engineers and other problems, and achieve easy-to-observe, increase the amount of dissolution, easy to create effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

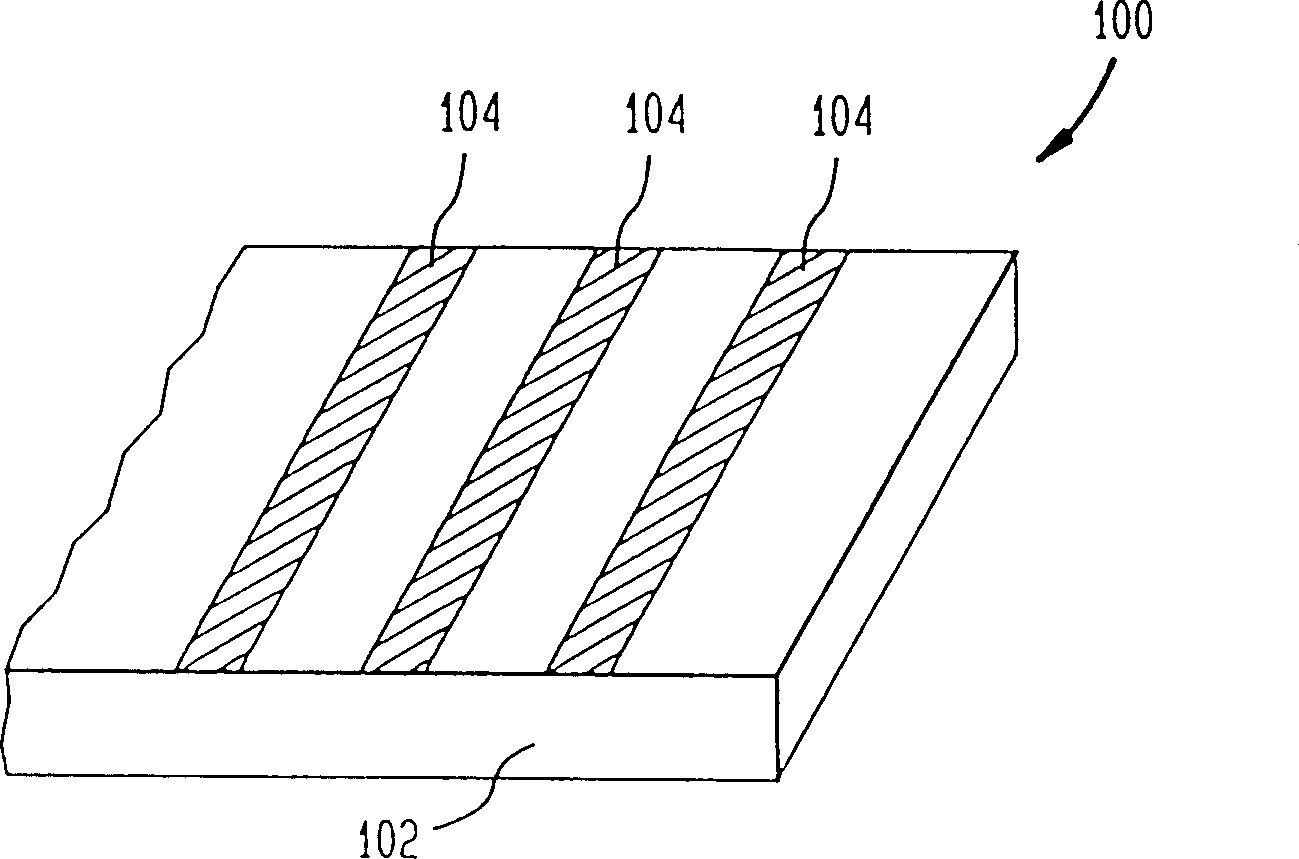

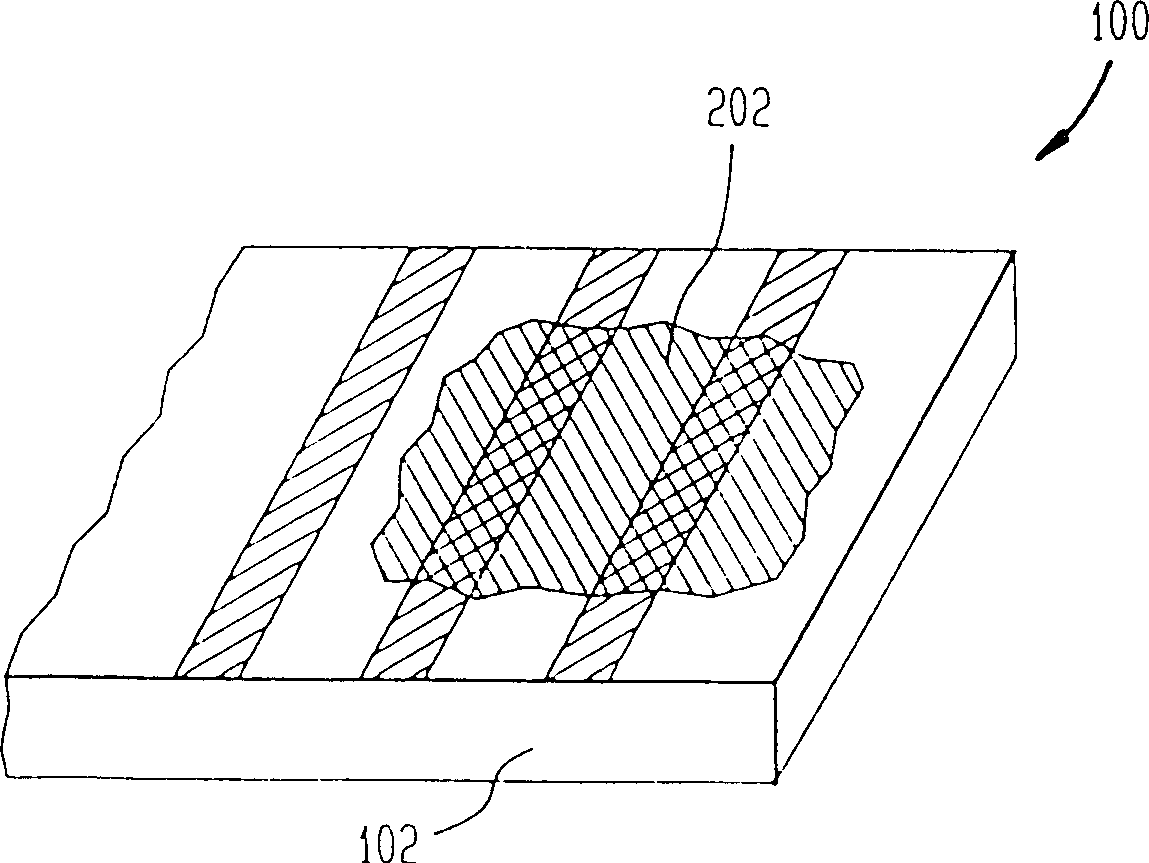

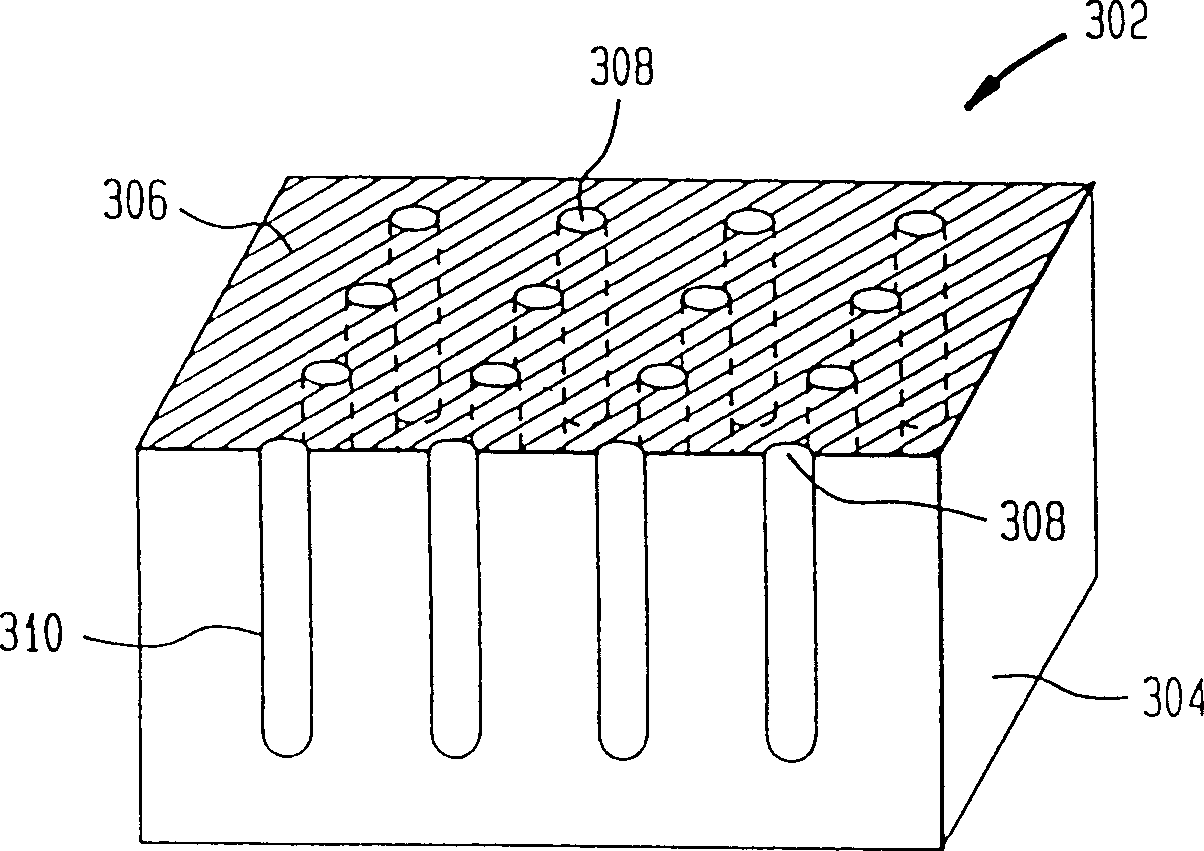

[0021] The present invention will be described in detail below with reference to several exemplary embodiments provided in the drawings. In the following description, some specific details are described in order to fully understand the present invention. However, it is obvious that for those skilled in the art, the present invention can be implemented without some or all of these specific details. On the other hand, the well-known process steps and / or structures are not described in detail, which is to make it easier to understand the present invention.

[0022] According to an embodiment of the present invention, an inventive silica stain formation technology is provided, which can significantly increase the amount of silicon dissolved in the cleaning process. By adding silicon hydrates, the silica stains remaining on the test structure after drying will be significantly enlarged and / or thickened, so that the use of ordinary optical monitoring equipment (eg, using a conventional ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical dimension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com