Combined prefabricated ballast bed suitable for shock absorption and noise reduction of railway tunnel

A technology of prefabricated roads and ballast beds, applied in the directions of roads, tracks, ballast layers, etc., can solve the problems of poor shock absorption and noise reduction, and achieve the effects of increasing the effective working area, reducing noise, and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

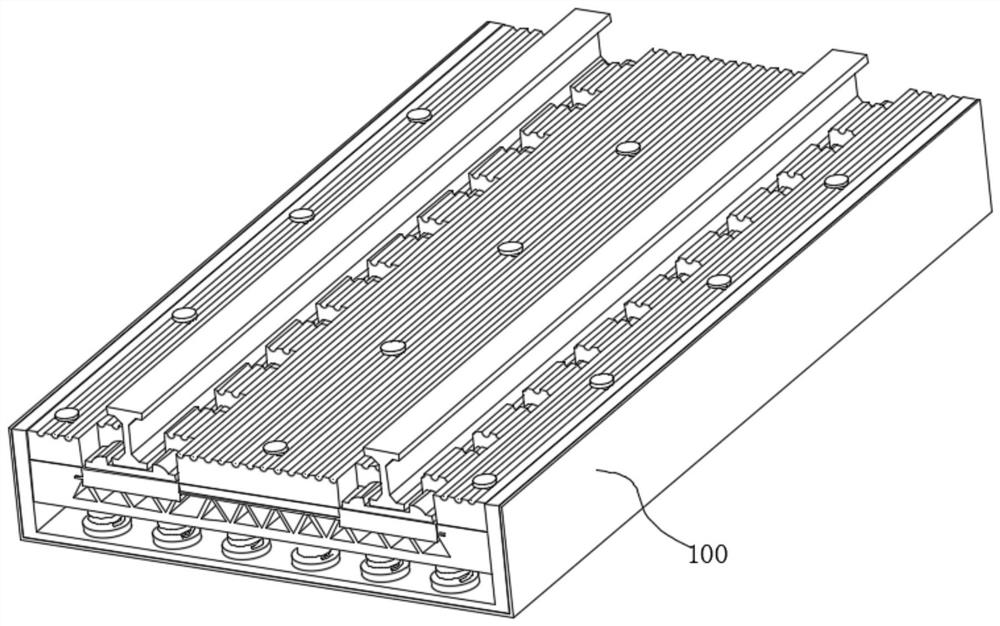

[0039] see figure 1 , the present invention provides a technical solution: a combined prefabricated ballast bed suitable for vibration and noise reduction in railway tunnels, including a ballast bed assembly 100 .

[0040] Among them, seefigure 1 , the ballast bed assembly 100 can effectively reduce the noise generated by the train running in the railway tunnel, greatly reducing the dynamic effect of the train, and the prefabricated shock-absorbing and noise-reducing ballast bed can ensure the quality of the project and improve the construction efficiency.

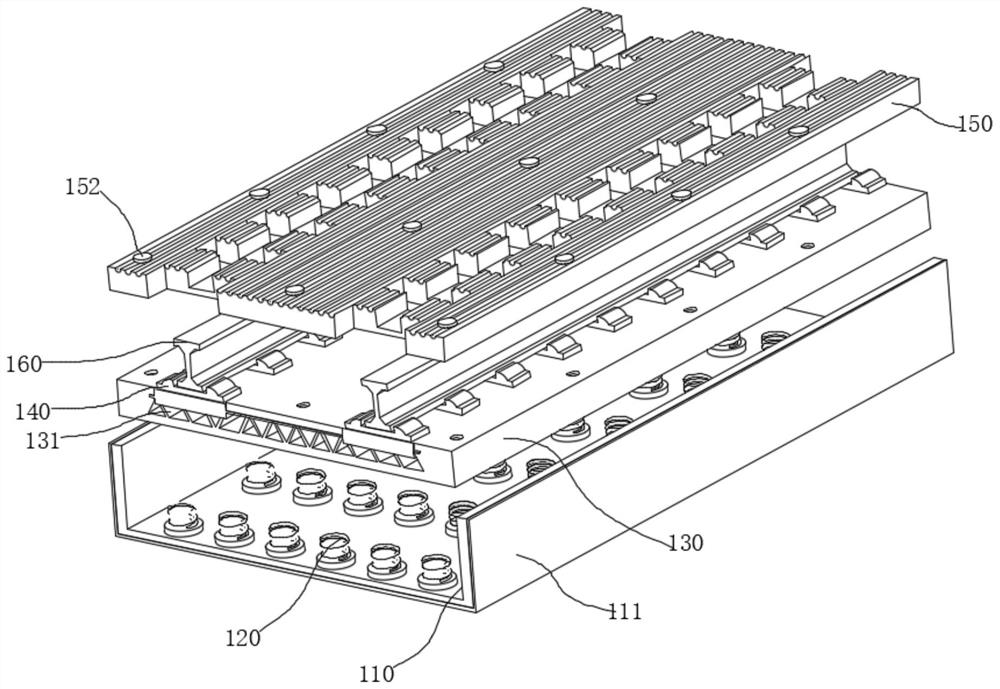

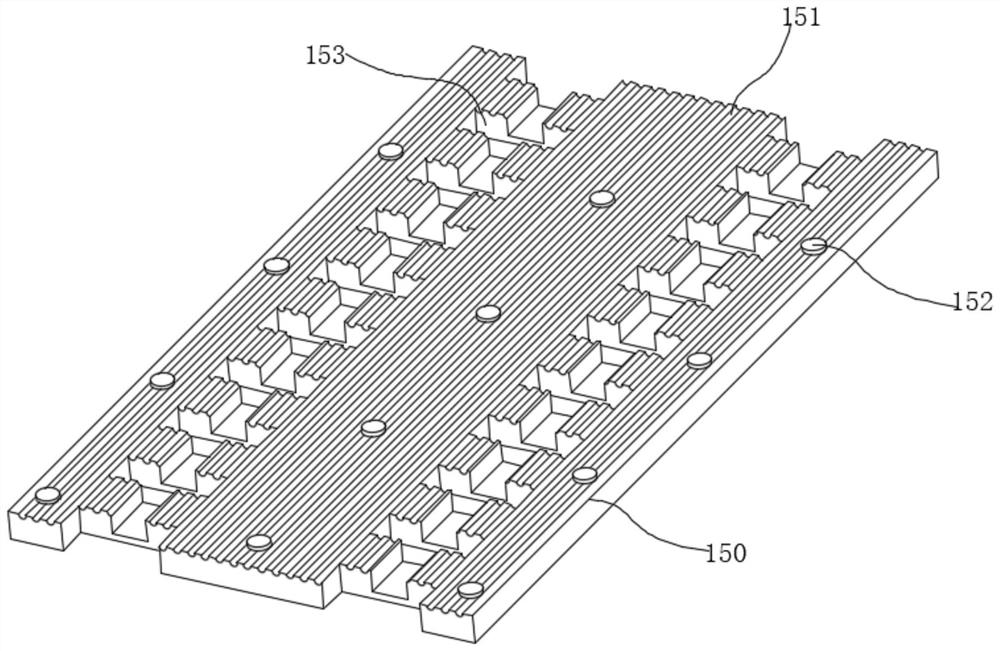

[0041] see figure 1 , figure 2 and image 3 The track bed assembly 100 includes a prefabricated shell 110, a shock absorber 120, a prefabricated track bed slab 130, a sleeper 140, a sound-absorbing plate 150 and a steel rail 160, the shock absorber 120 is arranged in the prefabricated shell 110, and the shock absorber 120 is provided with a plurality of And they are respectively evenly distributed between the prefabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com