Novel cantilever scaffold building method for high-assembly-rate building

A technology of cantilevered scaffolding and construction, applied to the scaffolding supported by the building structure, scaffolding accessories, buildings, etc., can solve the problems of easily damaged concrete beams, instability, and increased construction costs, so as to reduce the hidden dangers of water seepage and leakage on the floor, The effect of reducing vertical displacement and saving engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

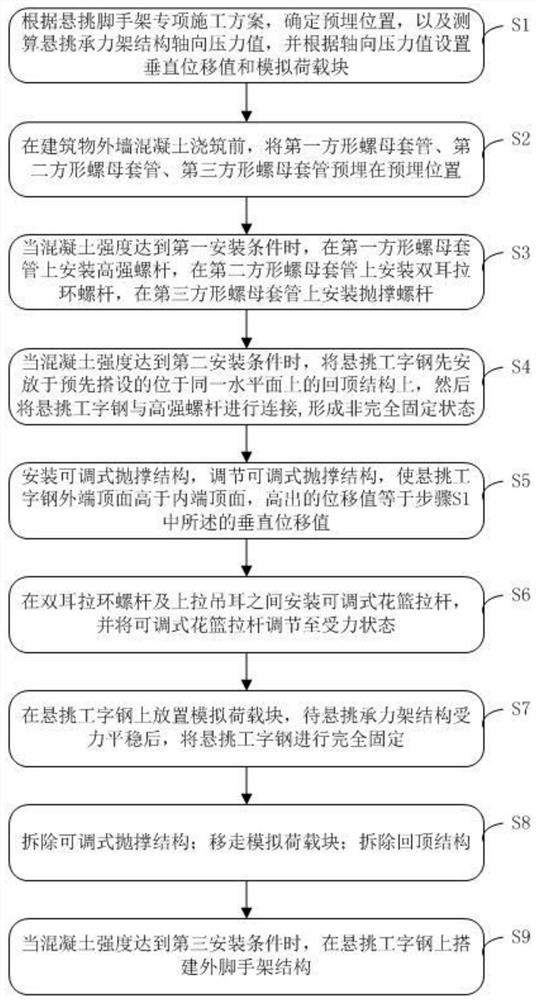

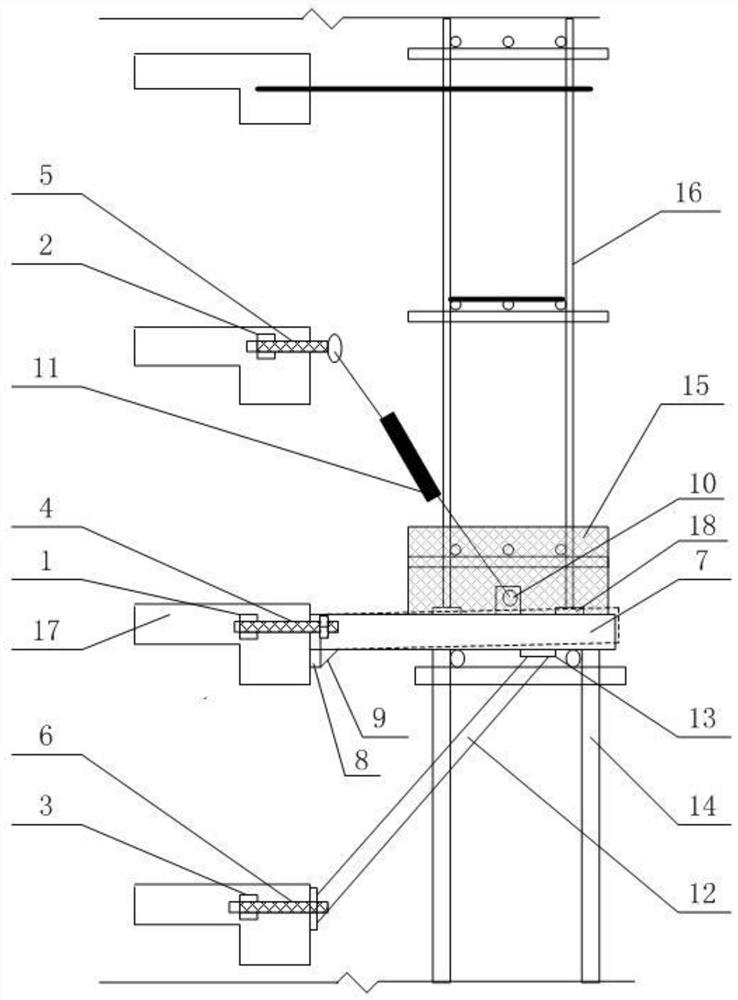

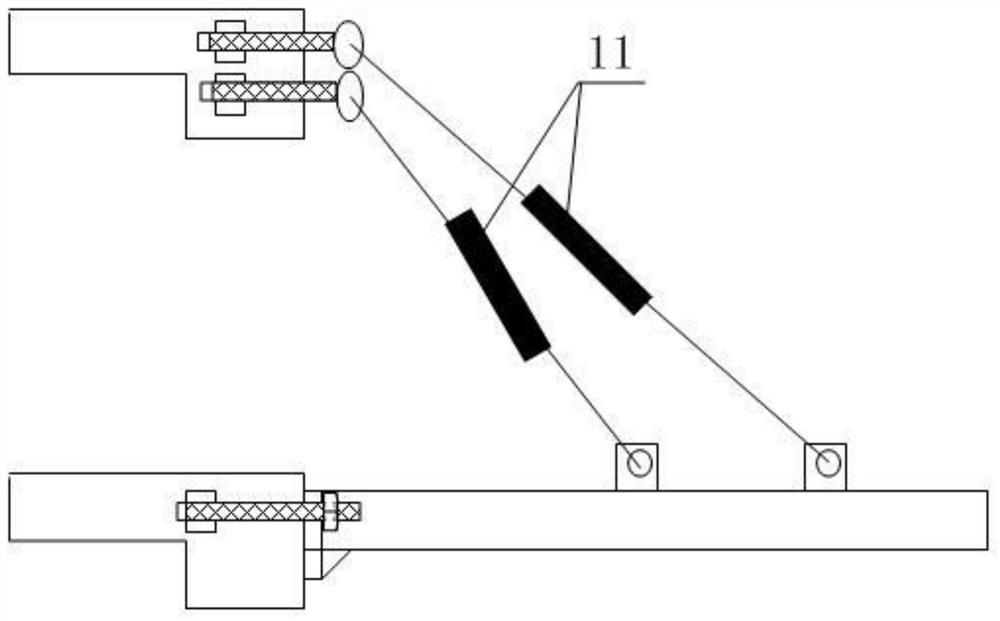

[0046] Such as Figure 1 to Figure 3 As shown, the present invention provides a novel cantilevered scaffold construction method for buildings with a high assembly rate. The cantilevered scaffold includes a first square nut sleeve 1, a second square nut sleeve 2, a second square nut sleeve as embedded parts. Three square nut sleeves 3, the high-strength screw rod 4 matched with the first square nut sleeve 1, the double-ear pull ring screw 5 matched with the second square nut sleeve 2, matched with the third square nut sleeve 3 The set throwing screw 6, the cantilevered I-steel 7 connected with the high-strength screw 4, the base plate 8 set on the inner end surface of the cantilevered I-steel 7, and the pull-up suspension set on the outer end surface of the cantilevered I-steel 7 Ear 10, adjustable turnbuckle pull rod 11 installed between the double-ear pull ring screw 5 and the pull-up lug 10, and the outer scaffold structure 16 arranged on the cantilevered I-beam 7, wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com