Automatic assembling production line for powder metallurgy brake lining of non-dovetail type motor train unit

A powder metallurgy and automatic assembly technology, which is applied in the field of processing and manufacturing railway product parts, can solve the problems of insufficient installation of support positioning seats, metal inlays and pieces falling, complex steel back structure of support positioning seats, etc., and achieve installation efficiency saving, The effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

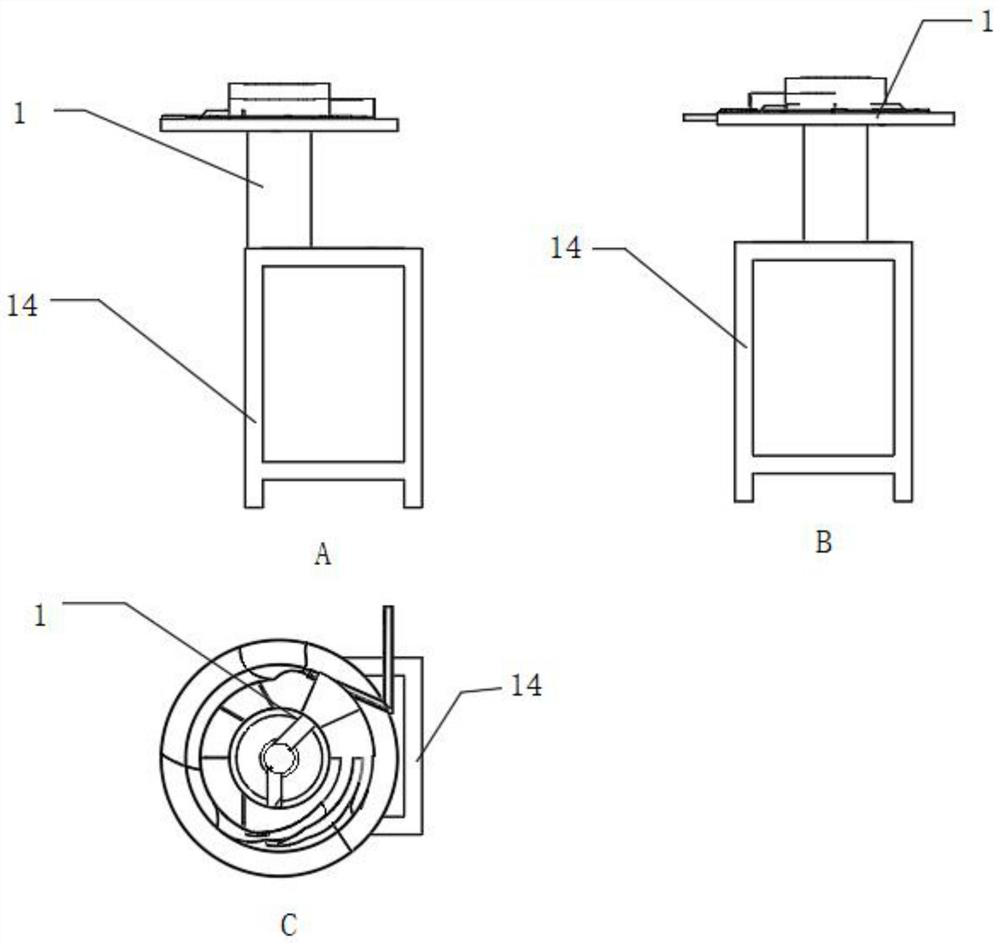

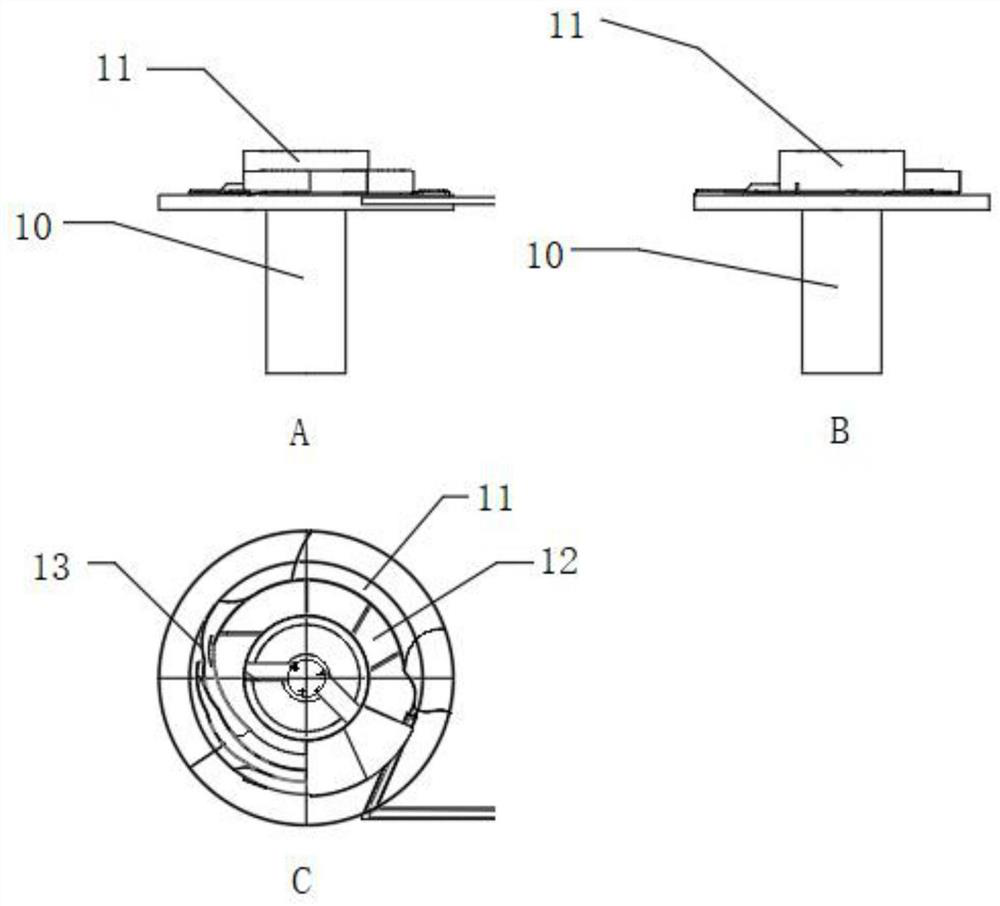

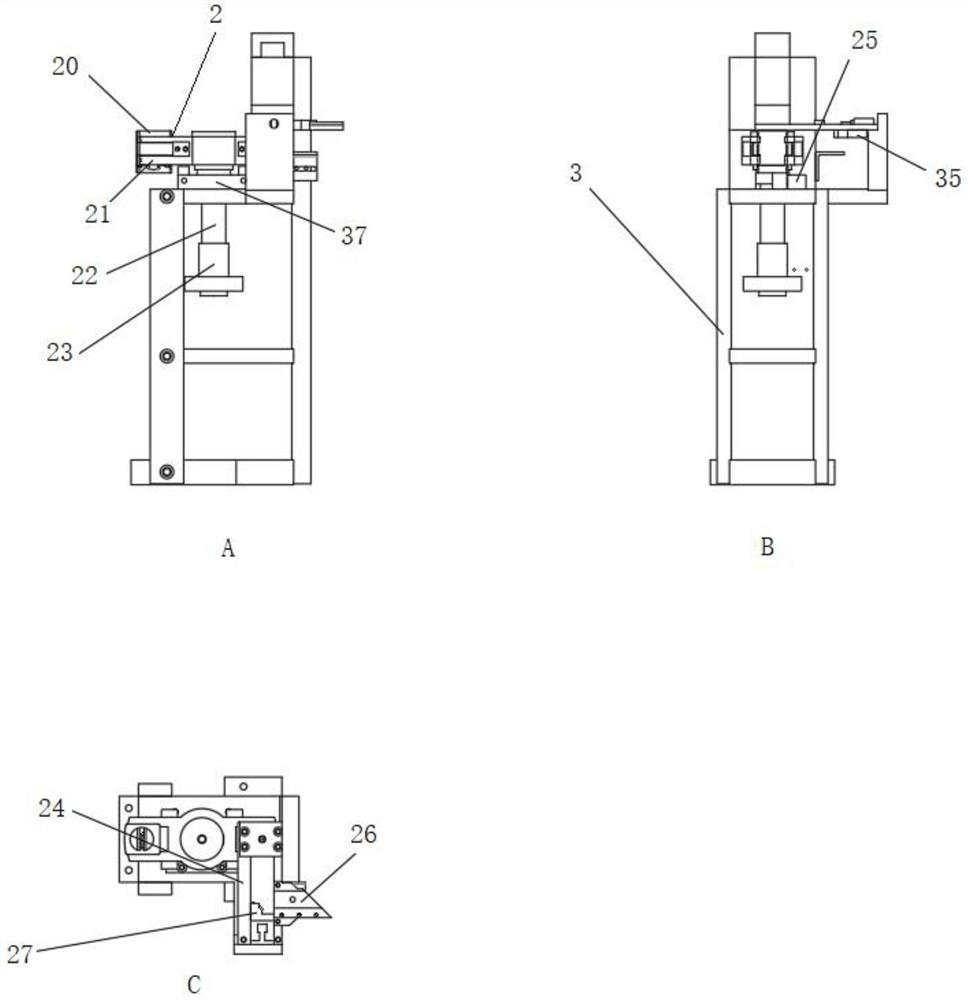

[0099] An automatic assembly line of powder metallurgy brake pads for non-dovetail EMUs, including a product component placement part, a product assembly part, a product marking and testing part 7, and a product delivery part; the product component placement part 8 is composed of a friction body The component grabbing transmission frame 80, the supporting positioning seat grabbing transmission frame 81, the steel back grabbing transmission frame 82 and the grabbing and placing manipulator 83; The circlip assembly part is combined; the product marking and testing part 7 can be divided into a product labeling part 70, a marking part 71 and a testing part.

[0100] The placement part of each part of the product is composed of a friction body component grabbing transmission frame, a support positioning seat grabbing transmission frame, a steel back grabbing transmission frame and 2 grabbing and placing manipulators; the support positioning seat The grab transport frame consists of...

Embodiment 2

[0153] The product transfer unit is assembled using welds and nuts and nuts.

[0154] The components of the grabbing device bracket of the friction body assembly are assembled and completed by welding. Place the longitudinal slide rail, motor, transverse slide rail and support positioning seat storage rack on the friction body component grabbing device bracket. Use nuts and nuts to complete the combination of the friction body assembly grabbing transverse slider and the friction body assembly grabbing device. Place the friction body assembly tray on the friction body assembly grabber bracket. Mount the manipulator on the bracket using nut screws. Install the friction body assembly and the position detection camera of the support positioning seat on the manipulator.

[0155] Use the welding method to complete the assembly of each part of the frame of the steel-backed grabbing and placing frame. Use nuts and nuts to complete the assembly of the steel-backed grab support. Us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com