Control method for safe combustion of industrial furnace

A control method and technology for industrial furnaces, which are applied in combustion methods, furnace control devices, and combustion control to achieve the effect of avoiding explosions and other safety accidents and reducing safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

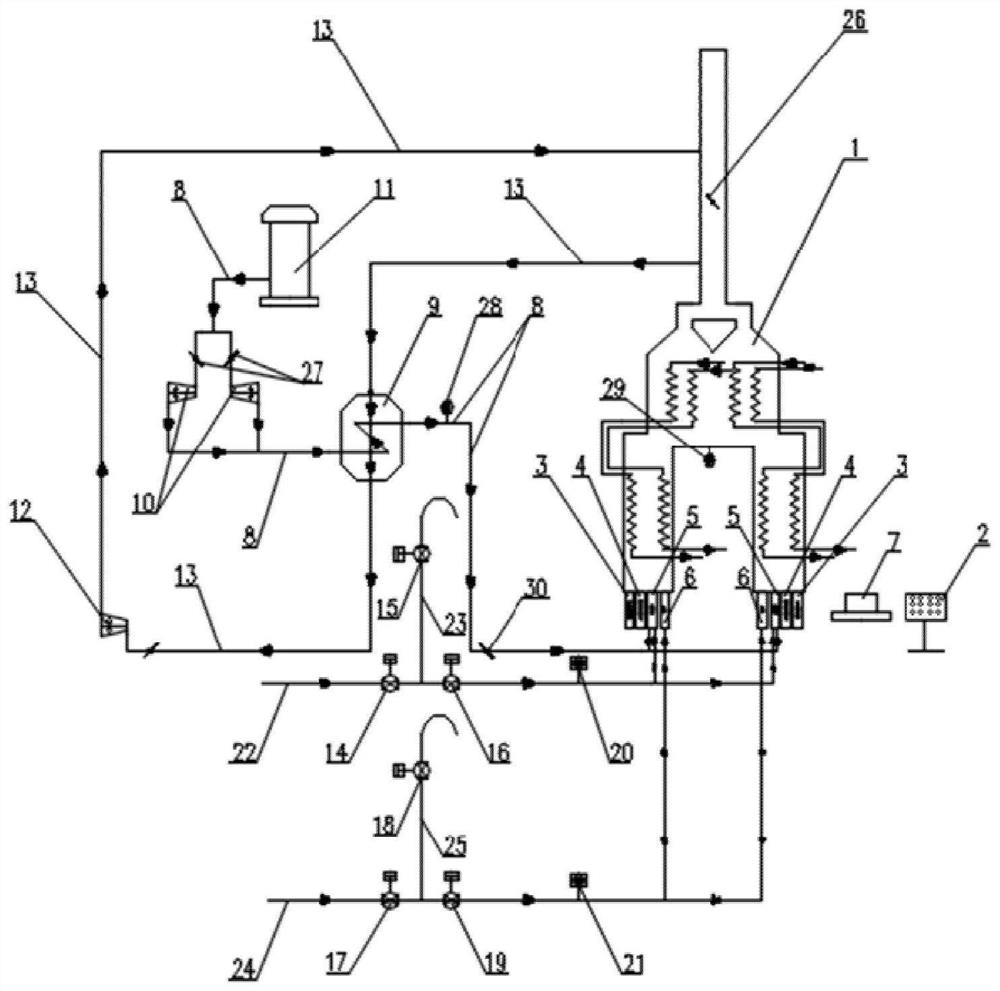

[0051] figure 1 The shown industrial furnace includes industrial furnace body 1, main burner fuel pipeline 22, pilot lamp fuel pipeline 24, combustion air duct 8, pilot lamp 6 and main burner 5; the volume of the furnace is 2050m 3 , take the following steps to carry out safe ignition and operation control of the industrial furnace:

[0052] S1: Leak detection of fuel lines

[0053] Through the sequential pressurization and pressure release of the main burner fuel pipeline 22 and the pilot lamp fuel pipeline 24, at the same time cooperate with the main flame fuel gas regulating valve 14, the main flame fuel gas vent valve 15 the main flame fuel gas cut-off valve 16 the pilot lamp fuel gas regulating valve 17 The switch of the fuel gas vent valve 18 and the fuel gas cut-off valve 19 of the permanent lamp. By comparing the pressure difference of the main flame fuel gas pressure measuring instrument 20 and the pilot light fuel gas pressure measuring instrument 21 before and aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com