Concrete mixture outlet temperature real-time monitoring system and method

A technology for real-time monitoring system and outlet temperature, applied in radiation pyrometry, temperature measurement of moving fluid, measuring device, etc., can solve problems such as untimely temperature feedback, unfavorable health, large dust at the outlet, etc., to achieve Avoid wear and temperature perception sluggishness, reduce pollution, ensure stability and real-time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

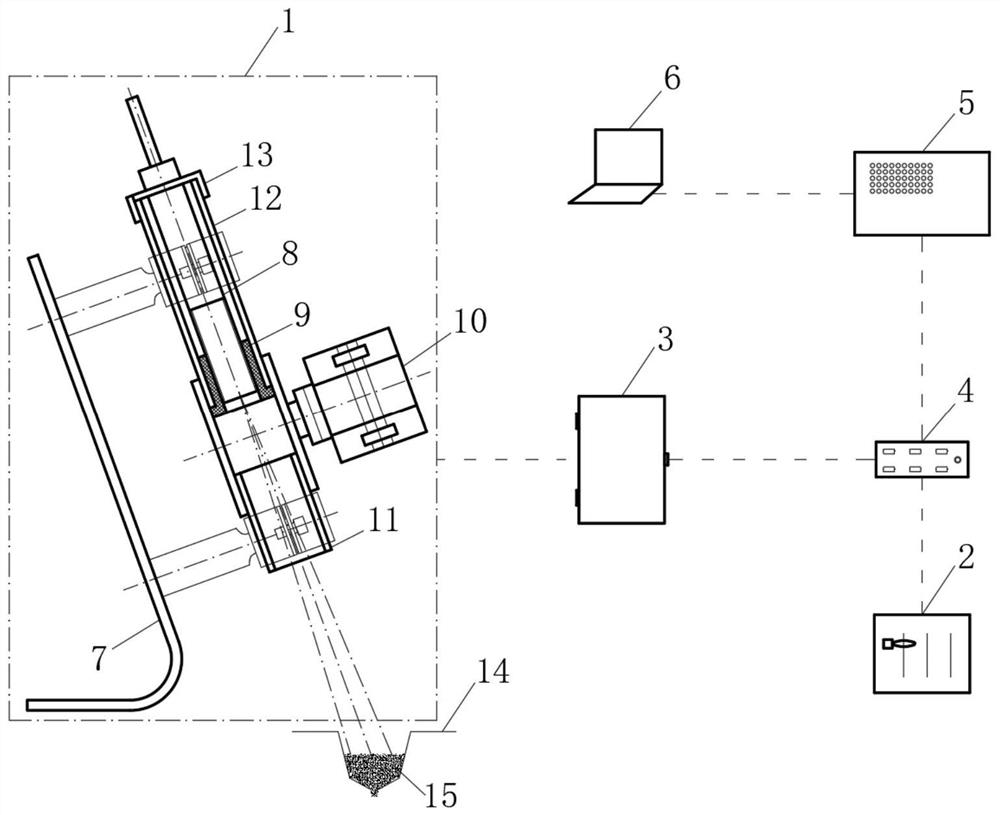

[0035] There is a concrete mixing station at a hydropower station site. On the second floor of the station, there is a receiving hopper under the outlet of the mixer. The concrete mixture unloaded from the mixer falls into the receiving hopper 14 for a short stay, and then continues to fall into the transport vehicle. Choose to weld and fix the temperature sensing device 1 on the upper edge of the receiving hopper 14 and the supporting steel column of the mixer, so that the probe is aimed at the position where more concrete is received at the bottom of the receiving hopper 14 . Bind and fix the measurement and control unit 3 on the railing in the station. The front host 4 and the unloading sensing device 2 are placed on the top surface of the control cabinet in the central control room, and the current transformer ring of the unloading sensing device 2 is hooked to the power supply line of the mixer in the power distribution cabinet.

[0036] The temperature sensor 8 is a CK-0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com