High-level waste bin nondestructive detector control system and method

A high-level radioactive waste and detector technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as shortening detection time, and achieve the effect of improving safety and ensuring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the technical problems solved by the present invention, the technical solutions adopted and the technical effects achieved clearer, the technical solutions of the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

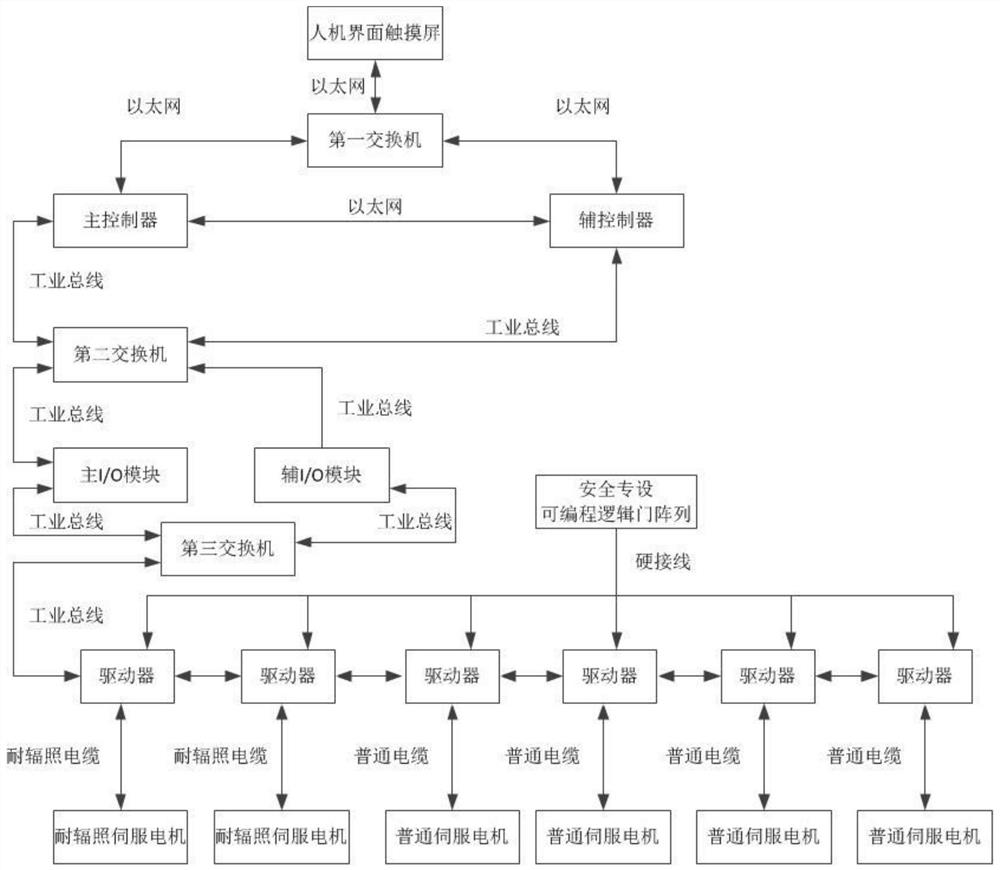

[0049] Such as figure 1 As shown, the embodiment of the present invention provides a high-level radioactive waste barrel non-destructive testing instrument control system, including: a main controller, an auxiliary controller, a main I / O module, an auxiliary I / O module, a man-machine interface touch screen, a safety expert A programmable logic gate array, a first switch, a second switch, a third switch, multiple drivers and multiple servo motors are set; the touch screen of the man-machine interface is connected to the first switch through Ethernet, and the first switch is connected to the main controller through Ethernet and the secondary controller, the main control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com