Drive and control integrated motor

A technology for driving and controlling circuit boards, which is applied in the direction of connection with control/drive circuits, electrical components, electromechanical devices, etc., to achieve the effects of simplifying manufacturing procedures, preventing over-positioning, and preventing unstable electrical connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

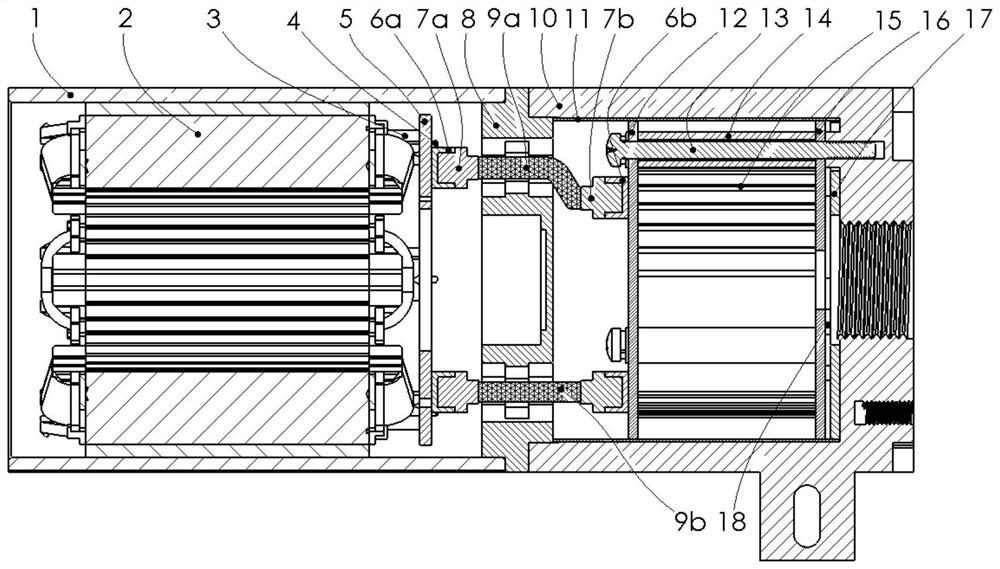

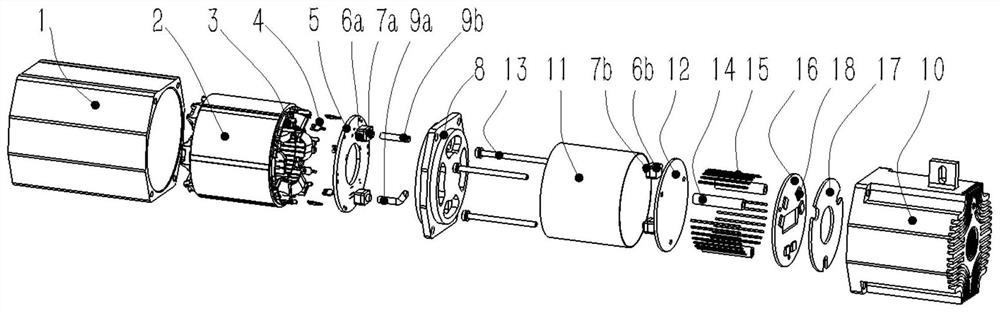

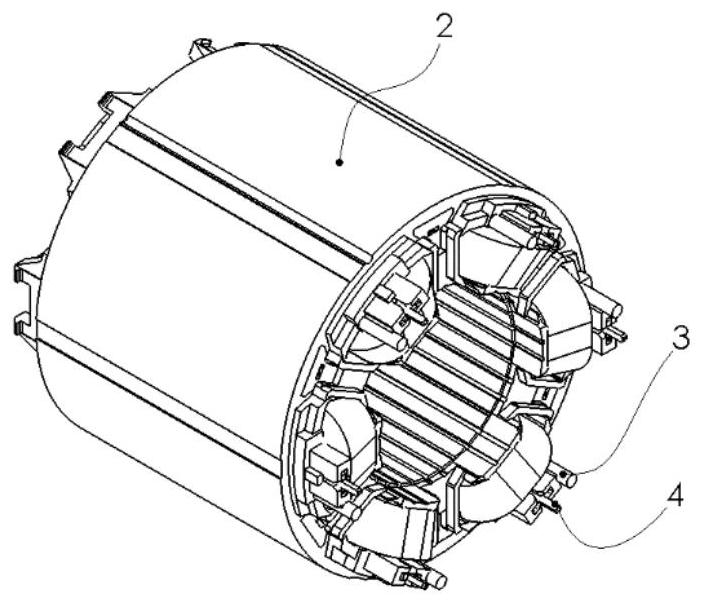

[0033] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail from four perspectives of electrical connection, structural support, electromagnetic shielding and power tube heat dissipation in combination with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. figure 1 and figure 2 Shown is a sectional view and a three-dimensional exploded view of the drive-control integrated motor of the present invention, and the structure is applicable to any type of motor.

[0034] Such as figure 1 , figure 2 As shown, the drive-control integrated motor mainly includes a housing 1, a stator 2, a winding frame 3, a puncture piece 4, a bus circuit board 5, a rectangular socket, a rectangular plug, an end cover 8, a cable, a heat dissipation base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com