Pre-filled wire laser ultra-narrow gap welding method for titanium alloy thick plate

A welding method and laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large welding deformation and welding stress, deterioration of joint performance, and influence of weld filling, etc., to achieve high precision and high Quality welding, low cost of technology transformation, and quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A laser ultra-narrow gap welding method for titanium alloy thick plate prefilled wire, which mainly includes the following steps:

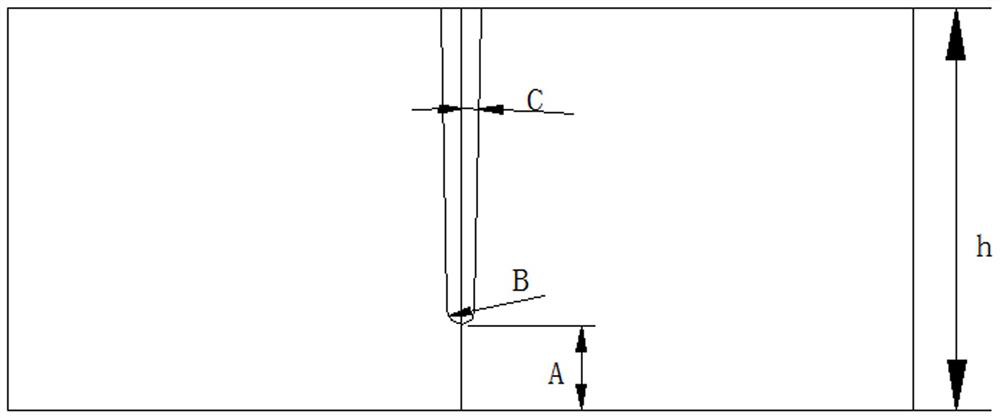

[0040] S1. Two TC4 plates with a thickness h of 45mm are butted, using such as figure 1 In the thick plate narrow gap groove structure shown, the blunt edge thickness A is 10mm, the fillet diameter B is 3mm, TC3 welding wire with a diameter of 3mm is used as the filling material, and the groove angle C is 1°;

[0041] S2, welding

[0042] S21. Carry out blunt edge laser welding. The welding process used for blunt edge welding is: laser power is 10KW, defocus amount is +15mm, and welding speed is 1000mm / min; there is no need to put welding wire into the blunt edge, and there is no gap left for the blunt edge Assembly, using laser self-fluxing welding;

[0043] S22. When filling, use 6KW power, 1000mm / min welding speed, and defocus + 30mm for welding. For the first time, put two welding wires, and the welding wires are arranged longitudinal...

Embodiment 2

[0047] A laser ultra-narrow gap welding method for titanium alloy thick plate prefilled wire, which mainly includes the following steps:

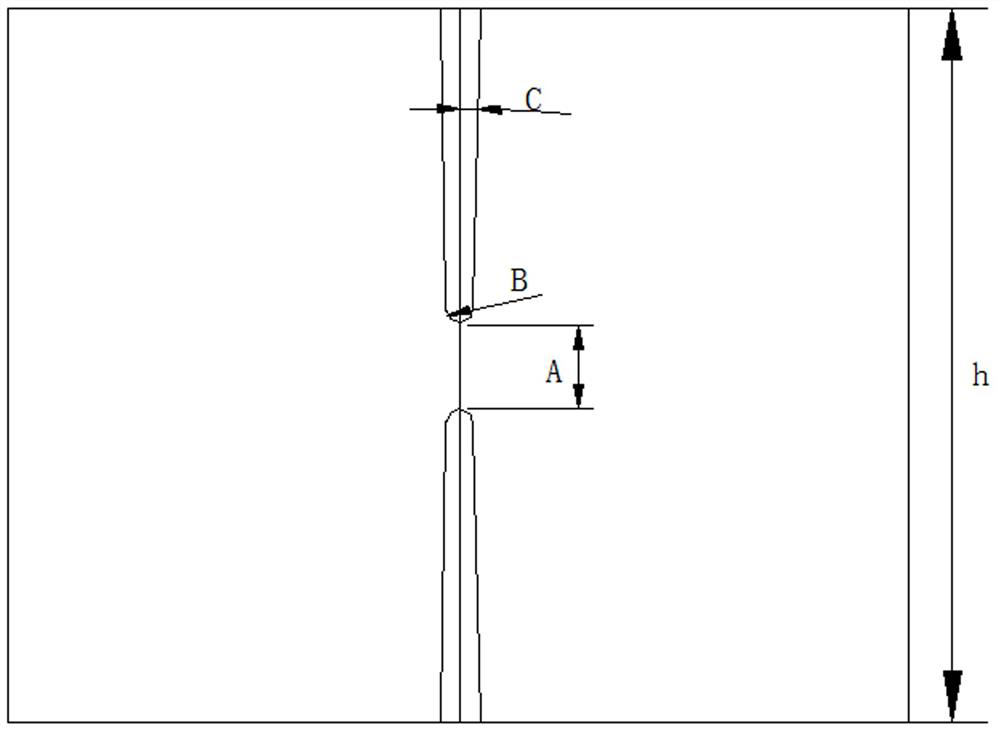

[0048] S1. Two TC4 plates with a thickness h of 90mm are butted, using such as figure 2 In the narrow gap groove structure of the titanium alloy thick plate shown, the groove needs to be welded symmetrically, that is, the other side is welded after one side is welded, which is beneficial to reduce welding deformation. The blunt edge thickness A is 10mm, the fillet diameter B is 3mm, TC3 welding wire with a diameter of 3mm is used as the filling material, and the groove angle C is 1.5°;

[0049] S2, welding

[0050] S21. Perform blunt edge laser welding. The welding process used for blunt edge welding is: laser power is 10KW, welding speed is 1000mm / min, defocus + 15mm;

[0051] S22. When filling, use 10KW power, 1000mm / min welding speed, and defocus + 30mm for welding. Put three welding wires in a single time. The welding wires are arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com