Laser machining precision metal plate device

A laser processing and precision technology, which is applied in the field of sheet metal processing, can solve the problems of laser processing over-burning, etc., and achieve the effects of reducing over-burning problems, simplifying programming, and maintaining height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

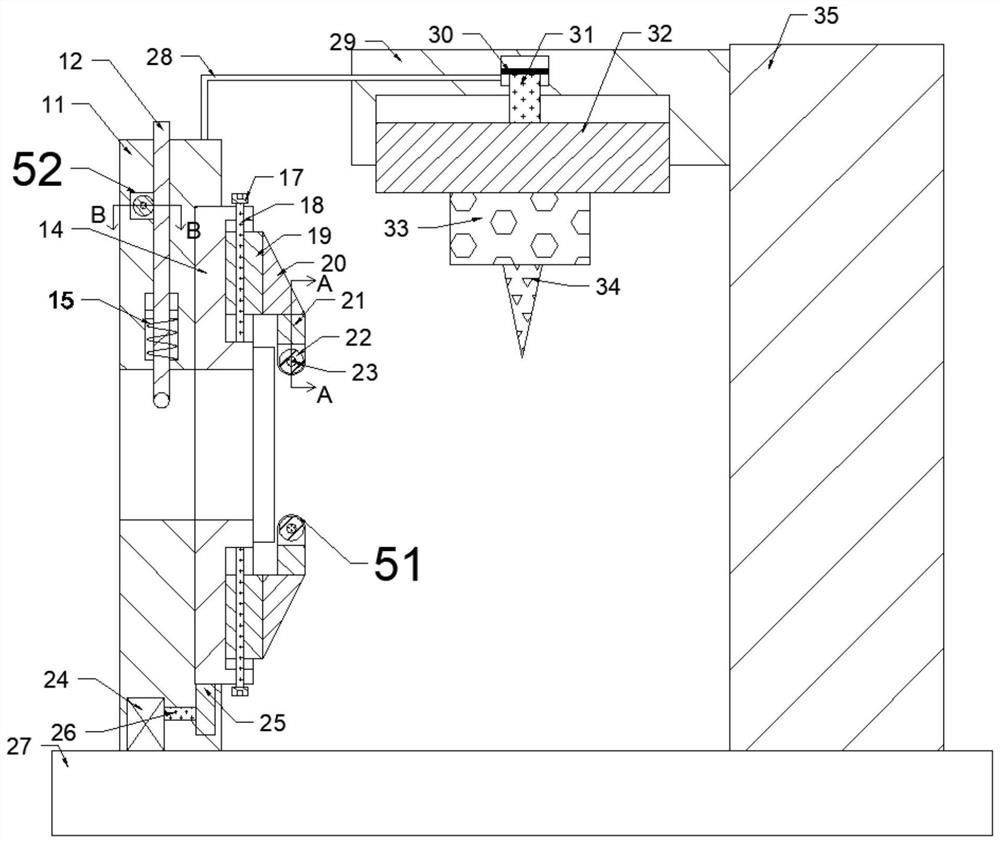

[0019] combined with Figure 1-4 The laser processing precision sheet metal device includes a clamping mechanism 51, and the clamping mechanism 51 is used for clamping and fixing the opposite tube and special-shaped tube;

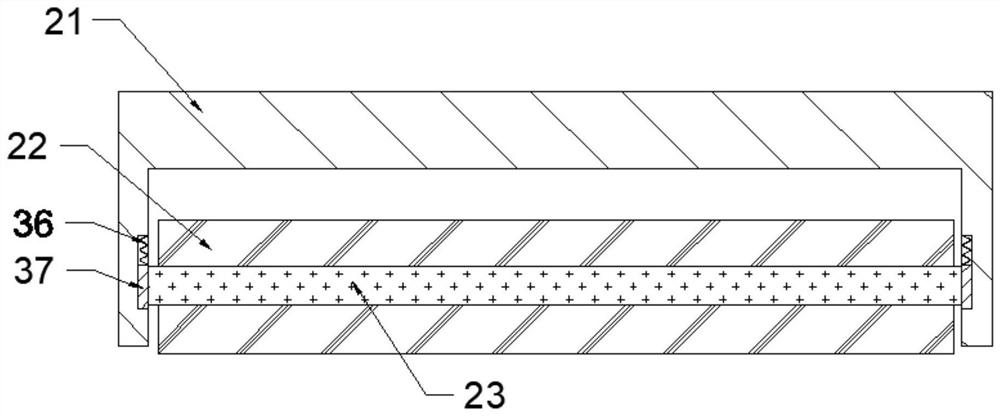

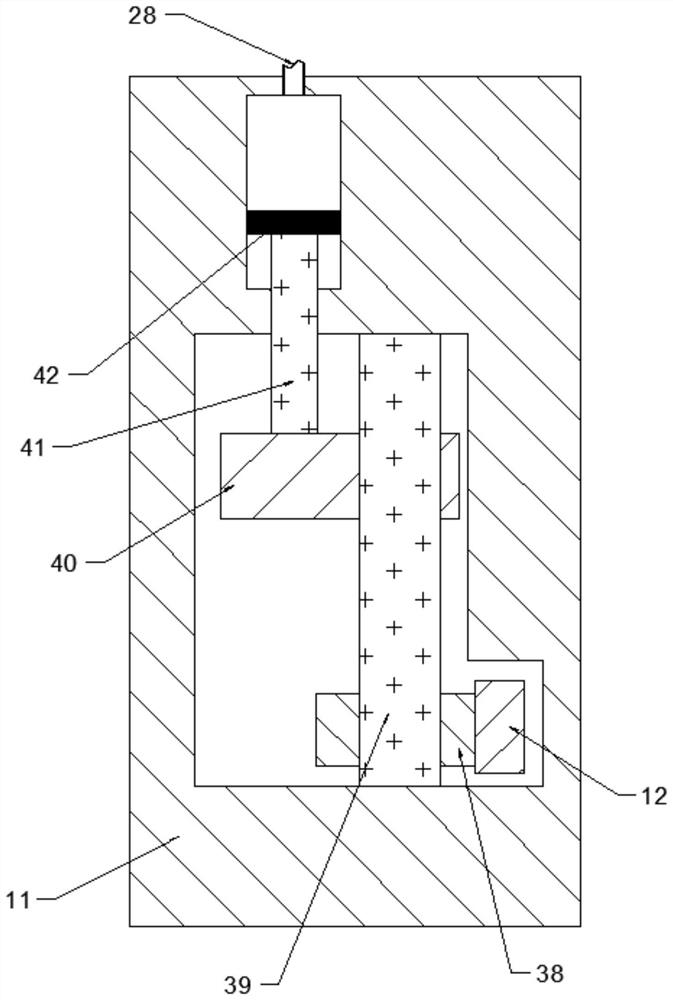

[0020] One side of the clamping mechanism 51 is provided with a distance-measuring adjustment mechanism 52, the distance-measuring adjustment mechanism 52 includes a distance-measuring rod 12 penetrating through the installation column 11, and the distance-measuring rod 12 and the installation column 11 are connected by a spring 15, the distance measuring rod 12 meshes with the distance measuring gear 38, the distance measuring gear 38 is fixedly connected to the distance measuring shaft 39, and the distance measuring shaft 39 is rotatably set on the installation column 11, and the distance measuring A distance measuring moving block 40 is threaded on the distance shaft 39, and a distance measuring piston rod 41 is fixedly connected to the distance measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com