5-cyano-8-acylaminoquinoline compound and preparation method thereof

A technology for amidoquinolines and compounds, applied in the field of 5-cyano-8-amidoquinolines and their preparation, to avoid metal catalysts and avoid competing reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

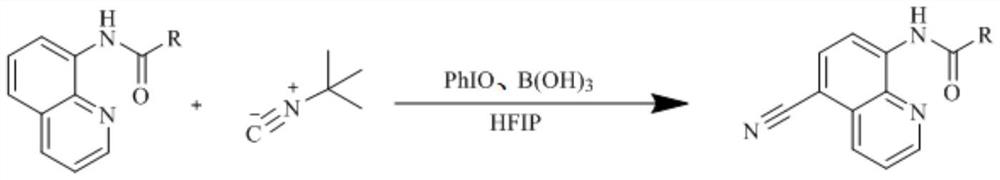

[0018] This specific embodiment provides a kind of preparation method of 5-cyano group-8-amidoquinoline compound, comprises the following steps: in reactor, adds 8-amidoquinoline, tert-butyl isonitrile, iodosobenzene ( Abbreviated as PhIO), boric acid (chemical formula is B(OH) 3 ) and hexafluoroisopropanol (abbreviated as HFIP), then stirred and reacted at 60-70°C for 12-16h to obtain the 5-cyano-8-amidoquinoline compound;

[0019] The obtained 5-cyano-8-amidoquinoline compound is further purified, including: adding water to the prepared 5-cyano-8-amidoquinoline compound, and then adding ethyl acetate to extract 3 -4 times to obtain the organic phase, the organic phase is distilled under reduced pressure to obtain the crude product, and the crude product is separated and purified by column chromatography; the material ratio of the water and the 8-acylaminoquinoline is (75-100 ) mL:1mmol, the volume ratio of the water to the ethyl acetate is (1.5-2):1. The mol ratio of descr...

Embodiment 1

[0026] This embodiment proposes a 5-cyano-8-acetylaminoquinoline, which is prepared by the following steps: add 0.2mmol 8-acetylaminoquinoline, 0.6mmol tert-butylisonitrile, 0.3mmol Iodophenone, 0.6mmol boric acid and 2mL hexafluoroisopropanol, and then add a No. 5 magnet, pass condensed water through the condenser tube from bottom to top, and then stir the reactor at 60°C for 12h to obtain the 5-cyano -8-Acetamidoquinoline;

[0027] The obtained 5-cyano-8-acetylaminoquinoline was further purified, including: adding 15 mL of water to the obtained 5-cyano-8-acetylaminoquinoline, and then adding 10 mL of ethyl acetate to extract 3 times to obtain Organic phase, the organic phase was distilled under reduced pressure to obtain a crude product, and the crude product was separated and purified by column chromatography to obtain purified 5-cyano-8-acetylaminoquinoline with a yield of 50%.

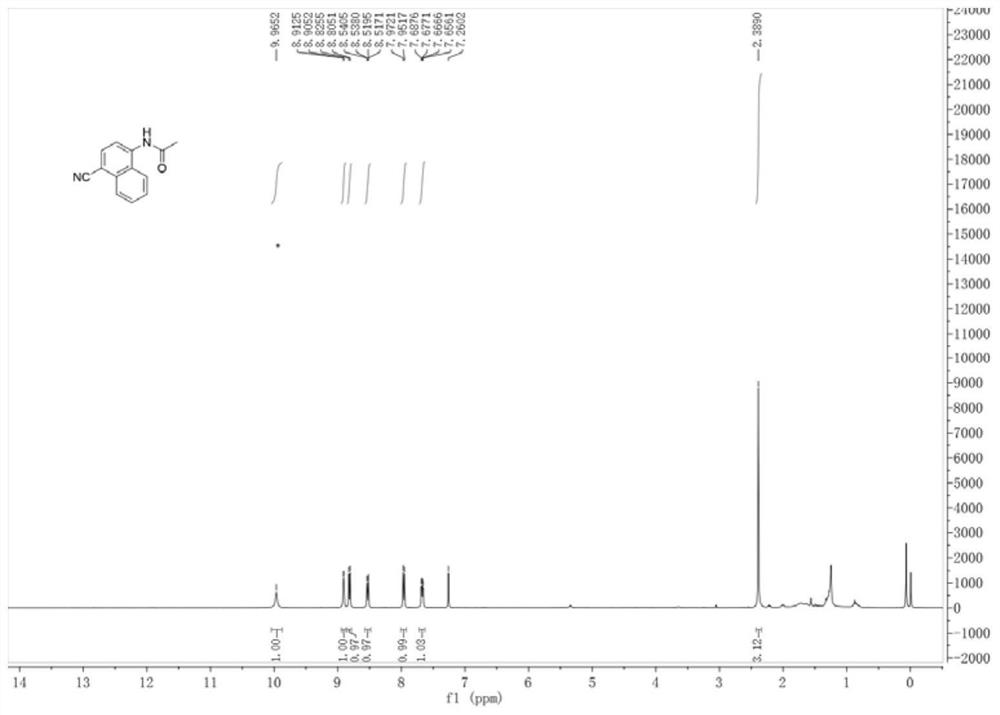

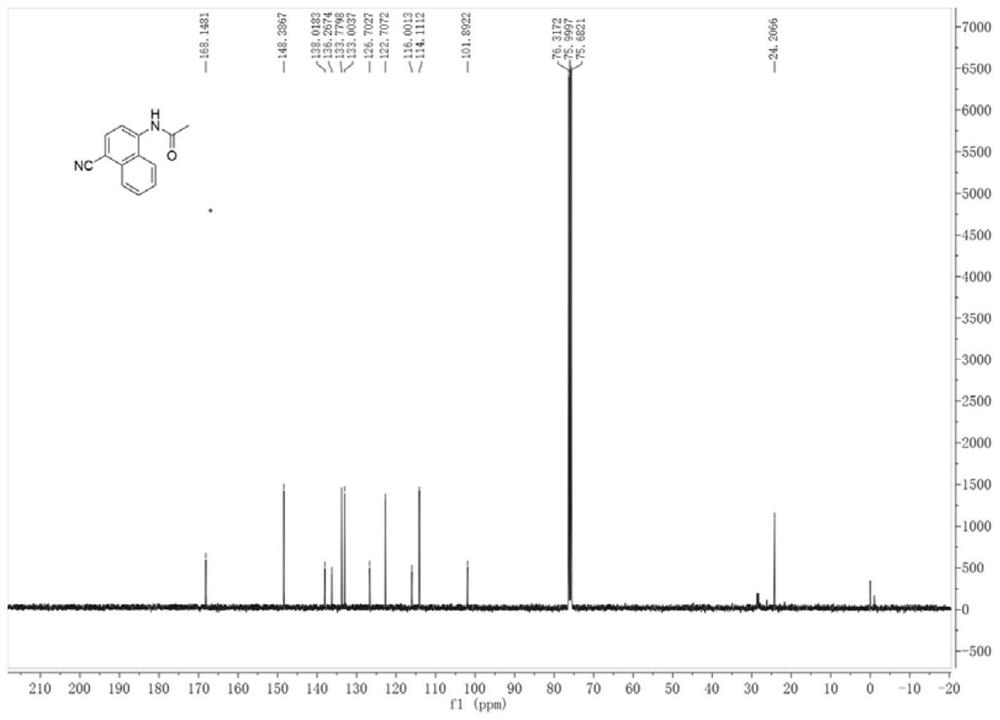

[0028] combine figure 1 and 2 The structure of the product was determined by H NMR and C NM...

Embodiment 2

[0032] This embodiment proposes a 5-cyano-8-acetylaminoquinoline, which is prepared by the following steps: add 0.2mmol 8-acetylaminoquinoline, 0.7mmol tert-butylisonitrile, 0.35mmol Iodosobenzene, 0.7mmol boric acid and 2.5mL hexafluoroisopropanol, and then add a No. 5 magnet, pass the condensed water through the condenser tube from bottom to top, and stir the reactor at 65°C for 14h to obtain the 5- Cyano-8-acetylaminoquinoline;

[0033] The obtained 5-cyano-8-acetylaminoquinoline was further purified, including: adding 15 mL of water to the obtained 5-cyano-8-acetylaminoquinoline, and then adding 10 mL of ethyl acetate to extract 3 times to obtain Organic phase, the organic phase was distilled under reduced pressure to obtain a crude product, and the crude product was separated and purified by column chromatography to obtain purified 5-cyano-8-acetylaminoquinoline with a yield of 48.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com