Fermentation system and method

A fermentation system and fermentation method technology, applied in the field of lactic acid fermentation, can solve the problems of increasing the usage of raw and auxiliary materials, increasing the number of sterilizations, and reducing the number of fermentation broth fermentation batches, so as to improve the utilization rate and production efficiency, and reduce the cultivation operation Pollution, the effect of shortening the fermentation inoculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

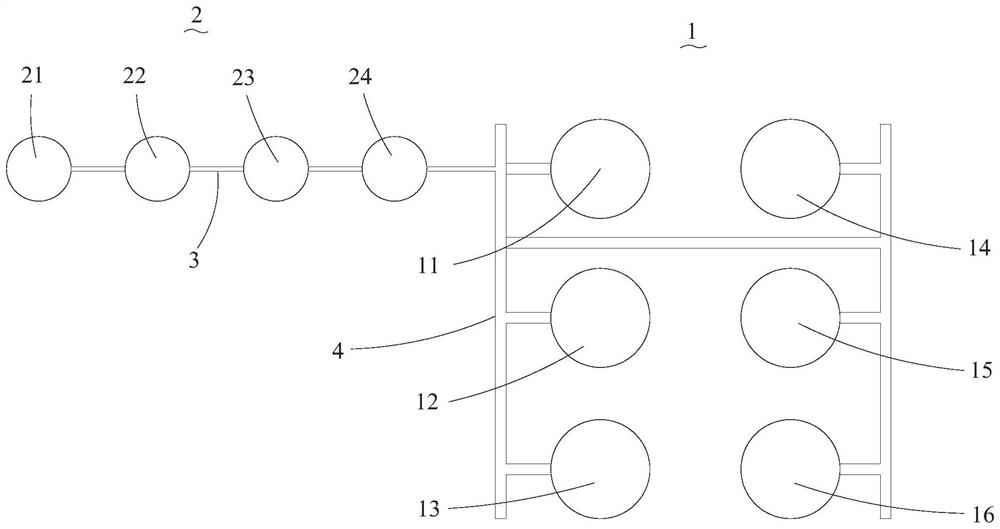

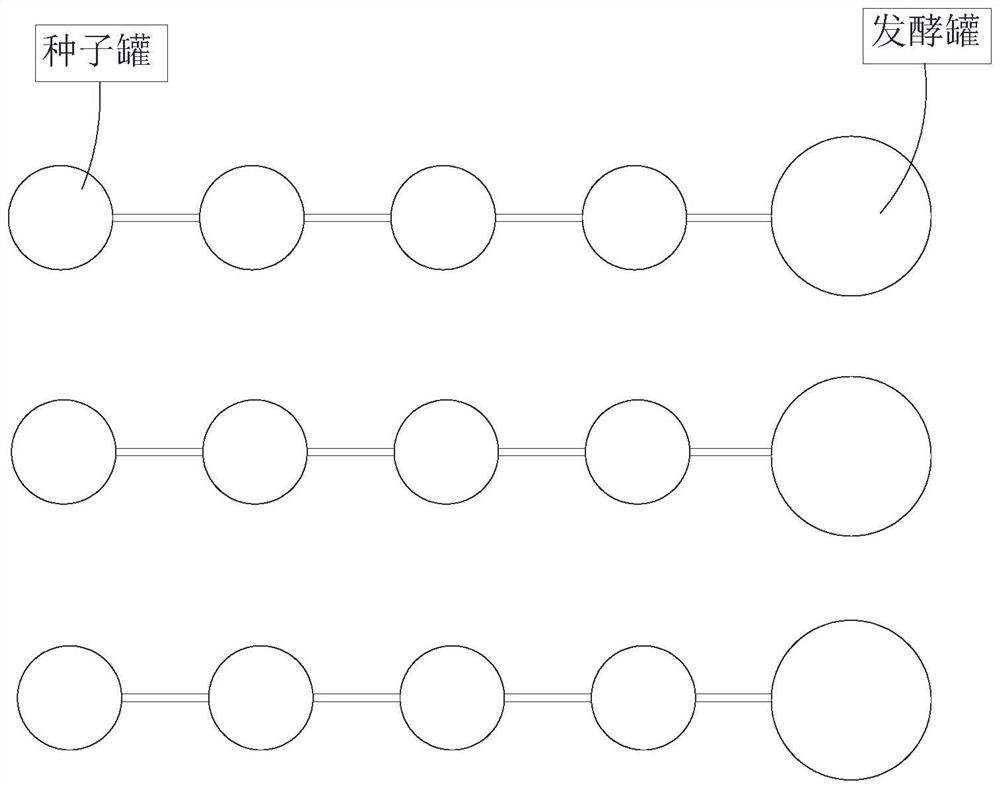

[0029] Please see figure 1 , The embodiment of the present invention provides a fermentation system, including several seed tanks 2 with different capacities, a transplanting tube 3 , several fermenting tanks 1 and a feeding tube 4 .

[0030] The transplanting tube 3 is connected with the seed tank 2, that is, the seed tanks 2 are connected sequentially through the transplanting tube 3, and are arranged in ascending order according to the capacity of the seed tank 2, and the feeding tube 4 is connected with the fermenter 1, so as to pass through the feeding tube 3. Feed pipe 4 enables fermenter 1 to carry out fermented liquid two by two, and transplanting pipe 3 is also connected with a fermenting tank 1, that is, the seed tank 2 with the largest capacity is connected with a fermenting tank 1 through a transplanting pipe 3, so as to cultivate mature The seeds are transported from the seed tank 2 to the fermenter 1.

[0031] Further, the fermentor 1 comprises a first fermente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com