A highly adaptable multi-form steel mesh mold for indoor construction

An adaptable and architectural technology, applied in the direction of architecture, building components, building structures, etc., can solve the problems of inconvenient changes in different forms, limited applications, etc., and achieve the effect of convenient watering operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

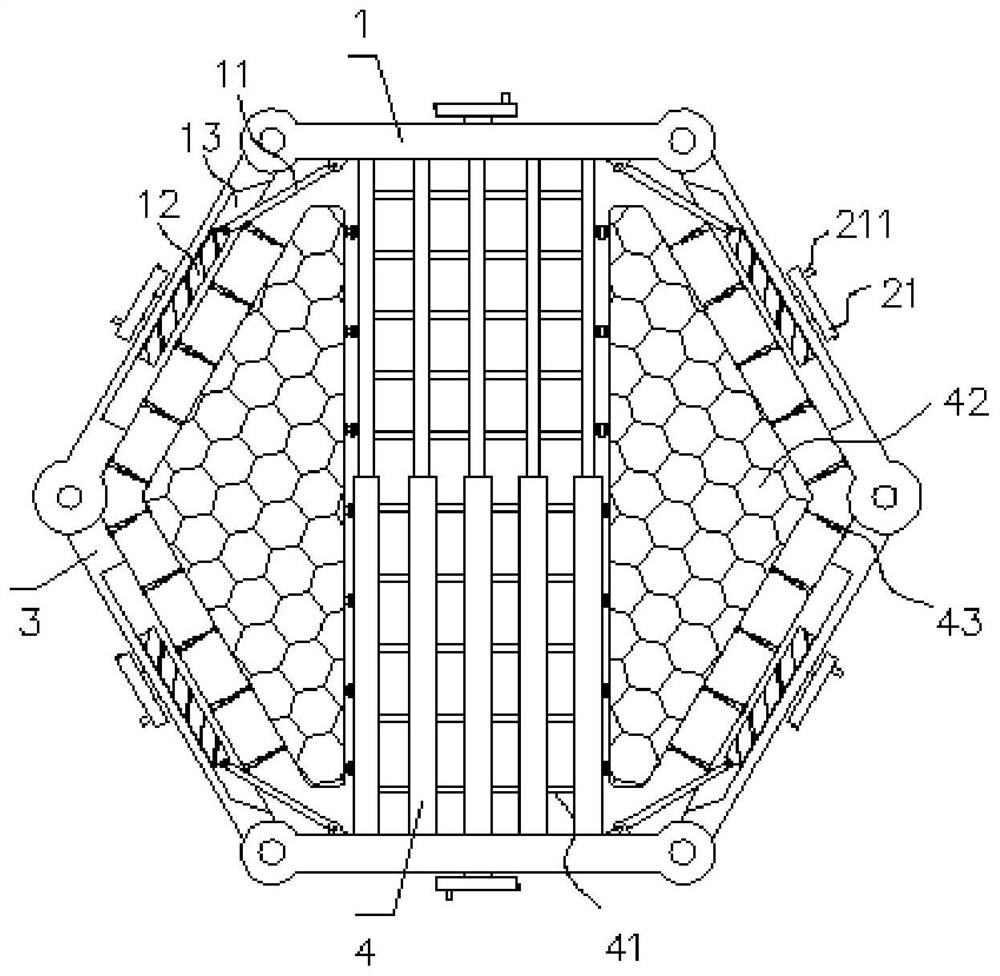

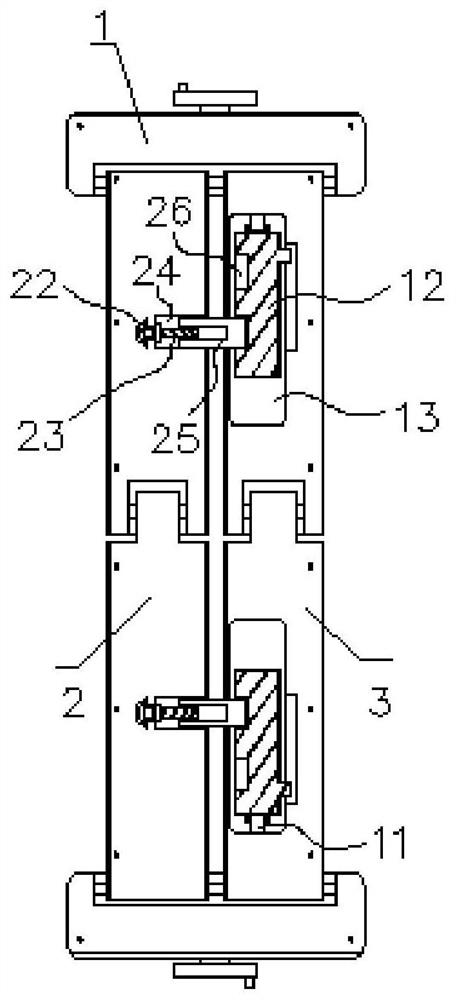

[0038] like Figure 1-Figure 7 As shown, a highly adaptable polymorphic stencil formwork for indoor construction of the present embodiment includes two sets of main formwork 1 arranged up and down correspondingly, and the two ends of each set of main formwork 1 are respectively hinged with second and third panels that are arranged side by side inside and outside. A pair of formwork 2 and a second secondary formwork 3, wherein the two sets of first secondary formwork 2 corresponding to the top and bottom of the same end, and the two sets of second secondary formwork 3 corresponding to the top and bottom of the same end are hinged; figure 1 and figure 2 As shown, the first auxiliary formwork 2 and the second auxiliary formwork 3 hinged at both ends of each main formwork 1 are symmetrically distributed at both ends of the main formwork 1, that is, a hexahedral steel mesh formwork structure is formed, and due to the hinged connection between the formwork Connection, so that the ...

Embodiment 2

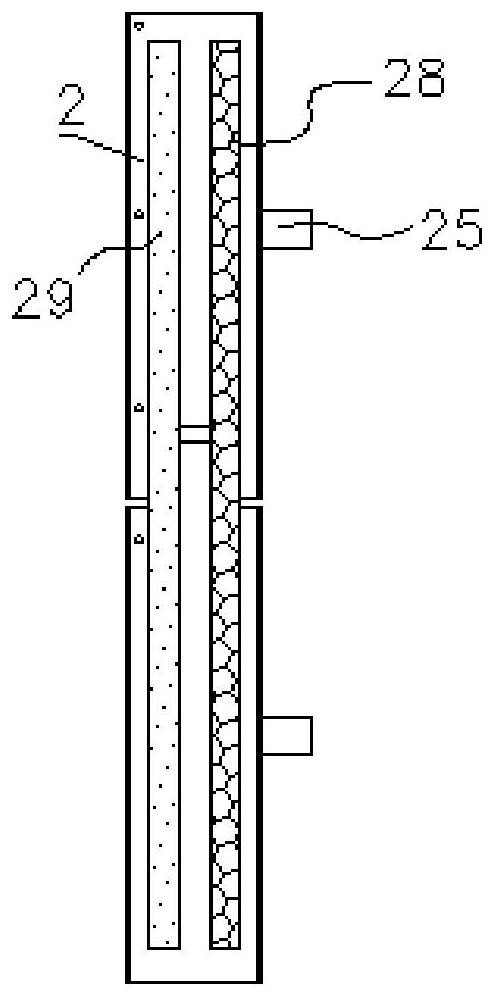

[0043] A highly adaptable polymorphic steel mesh mold for indoor construction of this embodiment, the basic structure is the same as that of Embodiment 1, and further, such as figure 1 As shown, a plurality of sets of vertical support telescopic rods are arranged between the main templates 1 distributed up and down, the vertical support telescopic rods are distributed at equal intervals and are connected with transverse screw rods 41, and the outer side of the vertical support telescopic rods is provided with elastic The steel mesh 42 and the elastic steel mesh 42 are fixed on the inner walls of the main template 1 and the second auxiliary template 3 through the elastic fixing member 43 to form a whole-surface type elastic steel mesh 42 laying structure. Specifically, the elastic fixing member 43 may adopt a structure such as an elastic fixing belt or an elastic fixing buckle that is common in the industry, which belongs to the conventional technology, and will not be described...

Embodiment 3

[0048] The basic structure of a highly adaptable polymorphic steel mesh mold for indoor construction of this embodiment is the same as that of the above-mentioned embodiment, and further, such as Figure 5 and Image 6 As shown, further, the outer walls of the main template 1 and the first sub-template 2 are also provided with a splicing mechanism for splicing and assembling, and multiple groups of steel mesh membranes are spliced through a connecting mechanism.

[0049] It is worth noting that in this embodiment, the splicing mechanism and the positioning mechanism in Embodiment 1 are both integrated on the knob 21, that is, as Figure 5 As shown, the knob 21 set on the main template 1 can only be used as a splicing mechanism, and there is no other structural setting of the positioning mechanism inside, while the knob 21 set on the first sub-template 2 can have both splicing and positioning functions. , using the corresponding structure provided on the outside of the knob ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com