Device for preventing high-temperature corrosion of water cooling wall of combustion boiler and boiler corrosion prevention method

A high-temperature corrosion and water-cooled wall technology, which is applied in the fields of boiler anti-water-cooled wall high-temperature corrosion prevention device and boiler anti-corrosion, combustion boiler anti-water-cooled wall high-temperature corrosion device and boiler anti-corrosion field, can solve boiler side wall water-cooled wall high-temperature corrosion and other problems, To achieve the effect of strengthening the oxidizing atmosphere near the wall, reducing the possibility and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

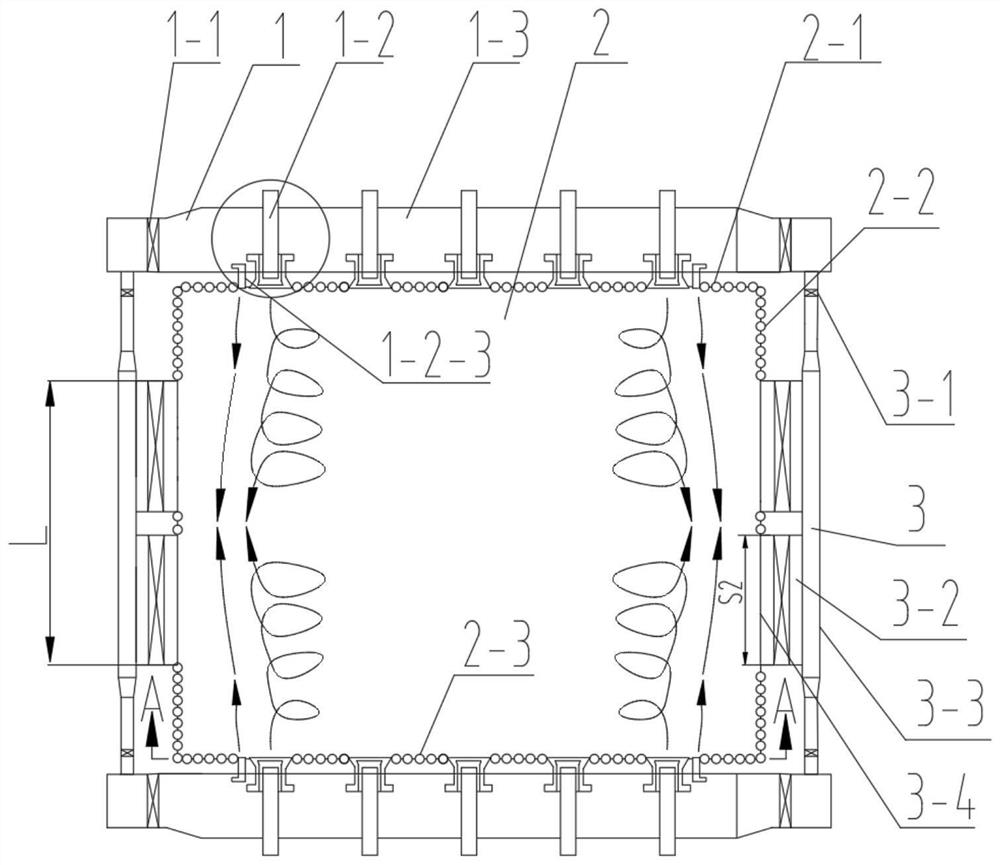

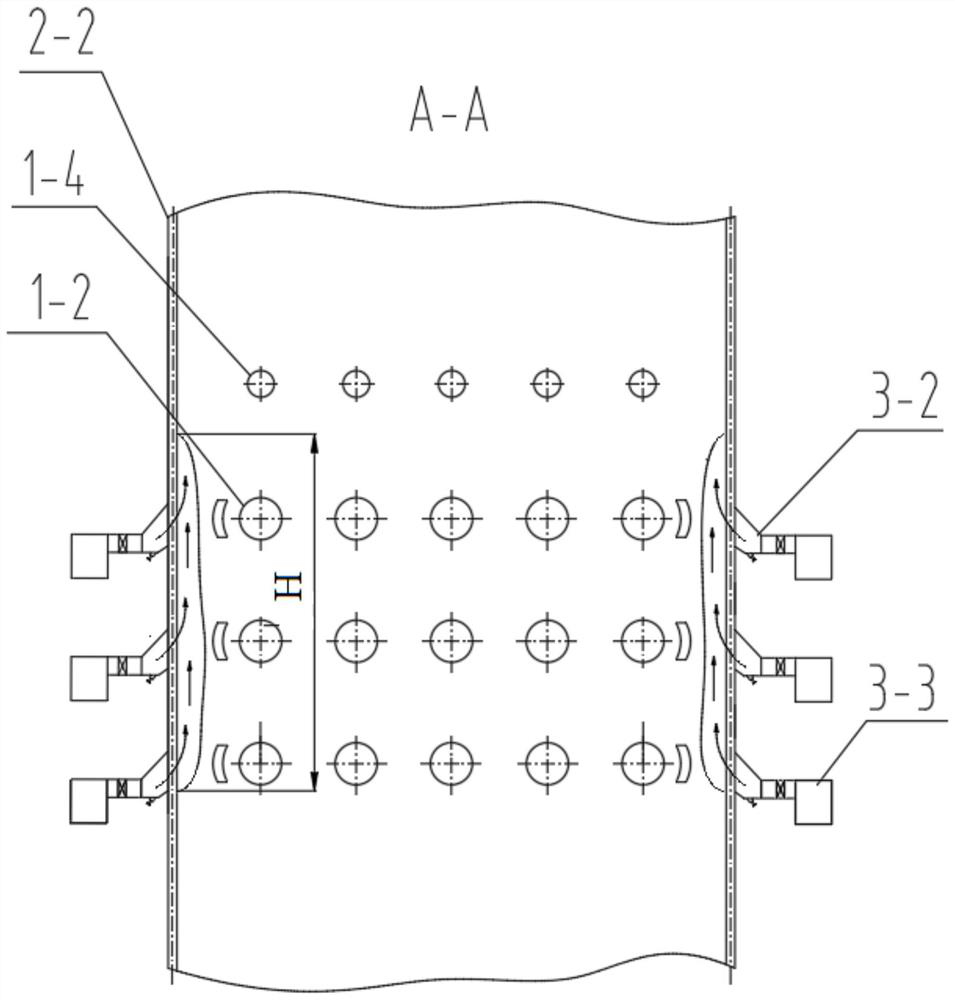

[0048] Specific implementation mode one: combine Figure 1-Figure 7 To illustrate this embodiment, the combustion boiler prevents high-temperature corrosion of the water wall, which includes a combustion system 1, a furnace 2 and two sets of wall-attached air systems 3; the furnace 2 includes a front wall 2-1, a rear wall 2-3 and Two side walls 2-2, the combustion system 1 includes two secondary air doors 1-1, two secondary air boxes 1-3, multiple burners 1-2 and multiple overfire air ports 1-4, The front wall 2-1, the rear wall 2-3 and two side walls 2-2 form the boiler body, the front wall 2-1 and the rear wall 2-3 are arranged oppositely, the two side walls 2-2 are arranged oppositely, and one secondary Damper 1-1 is installed on the front wall 2-1, and another secondary air door 1-1 is installed on the back wall 2-3, and a secondary air bellows 1-3 and a plurality of combustion air boxes 1-3 are installed on the front wall 2-1 A secondary air box 1-3 and a plurality of bu...

specific Embodiment approach 2

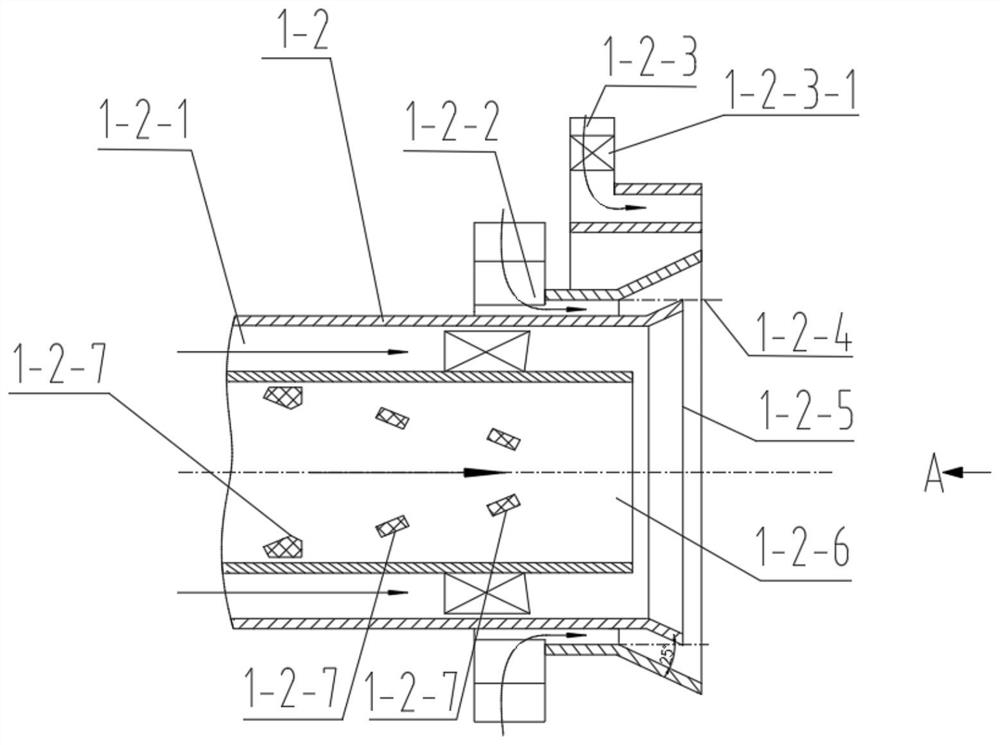

[0049] Specific implementation mode two: combination figure 1 and image 3 Describe this embodiment, the high-temperature corrosion prevention device for the water wall of the combustion boiler described in this embodiment, the burner 1-2 includes an inner secondary air swirler 1-2-1, an outer secondary air swirler 1-2-2 , Outer secondary air nozzle 1-2-4, inner secondary air nozzle 1-2-5, primary air pipe 1-2-6 and three conical pulverized coal separators 1-2-7; three conical The pulverized coal separator 1-2-7 is arranged in the primary air pipe 1-2-6 along the length direction, and the inner secondary air nozzle 1-2-5 and the outer secondary air nozzle 1-2-4 are arranged in sequence from the inside to the outside Outside the primary air duct 1-2-6, the inner secondary air cyclone 1-2-1 is installed inside the inner secondary air nozzle 1-2-5 outside the primary air duct 1-2-6, and the outer secondary air The wind cyclone 1-2-2 is installed at the outer secondary air nozzl...

specific Embodiment approach 3

[0050] Specific implementation mode three: combination figure 1 and image 3 To illustrate this embodiment, the device for preventing high-temperature corrosion of the water-cooled wall of the combustion boiler described in this embodiment also includes a plurality of offset high-temperature corrosion-resistant air ducts 1-2-3; the offset high-temperature corrosion-resistant air ducts 1-2-3 are Arc-shaped pipe, air door 1-2-3-1 is installed on the offset high-temperature corrosion-resistant air duct 1-2-3, and the offset high-temperature corrosion-resistant air duct 1-2-3 is installed on both sides of the front wall 2-1 close to On the burner 1-2 at the position of the side wall 2-2, the offset high-temperature corrosion-resistant air duct 1-2-3 is installed on both sides of the rear wall 2-3 close to the burner 1-2 at the position of the side wall 2-2. Other compositions and connection methods are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com