Wall-attached wind nozzle, boiler and boiler system

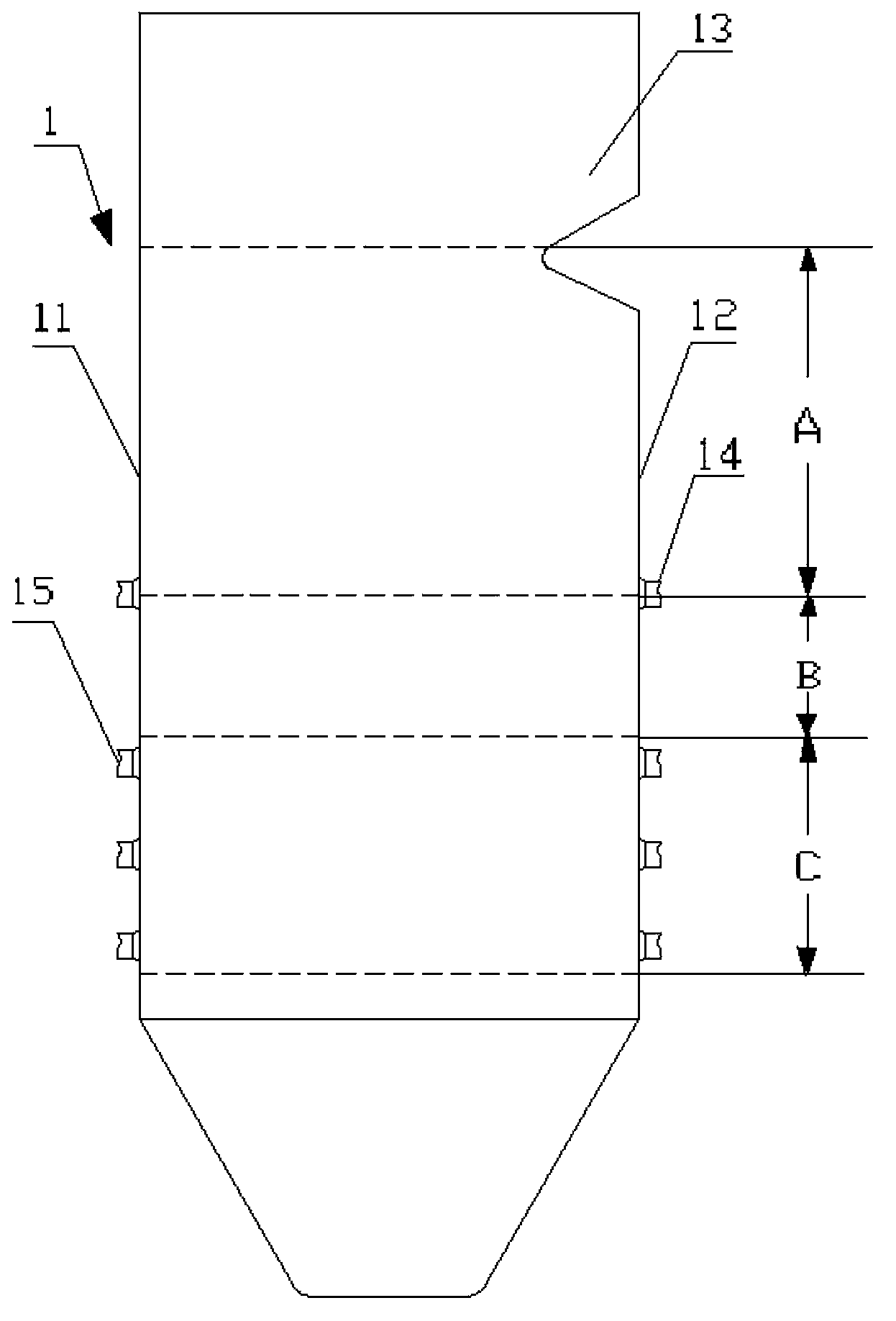

A wall-mounted air and nozzle technology, which is used in boiler systems, wall-mounted air nozzles and boiler fields, can solve the problems of increased high temperature corrosion of the water wall of side wall 13, increased temperature, and less obvious high temperature corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the accompanying drawings and specific embodiments are combined below. It should be noted that, for ease of understanding and brevity of description, the description of the boiler and the wall-attached air vent will be combined below, and the beneficial effects will not be discussed repeatedly.

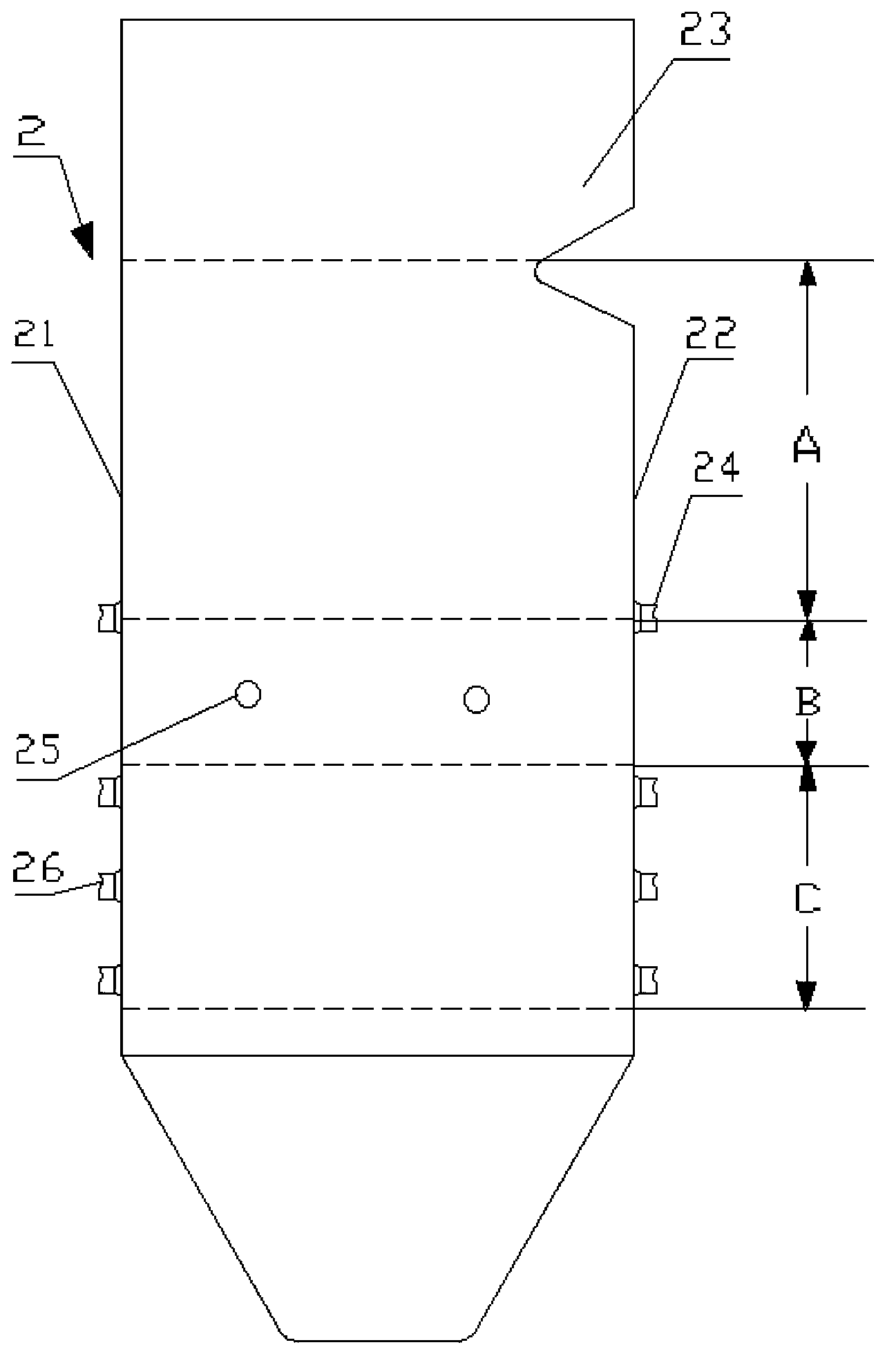

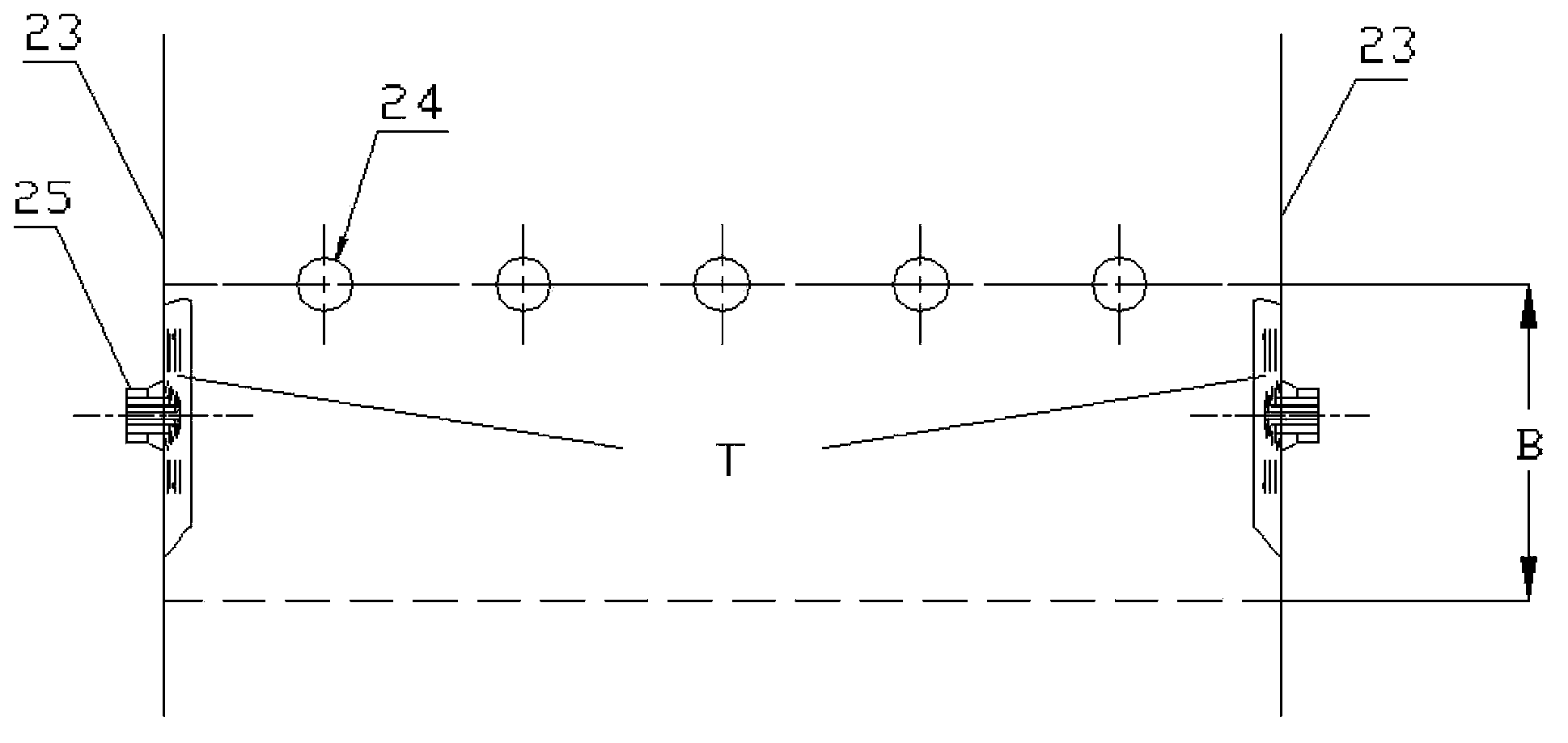

[0050] Please refer to Figure 2-4 , figure 2 A schematic diagram of a specific embodiment of the boiler provided by the present invention; image 3 for figure 2 The right view of the recovery area in the middle; Figure 4 for image 3 Schematic diagram of the structure of the wall-adherent wind nozzle.

[0051] The wall-attached air nozzle 25 in this embodiment is used to spray the overfired air, and can be located on the wall of the boiler 2. The wall of the boiler 2 usually includes a front wall 21, a rear wall 22 and two side walls 23, and any one wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com