Chamber cooling unit of heat treatment furnace

A heat treatment furnace and cooling unit technology, applied in furnace cooling devices, electrical components, drying chambers/containers, etc., can solve the problems of insufficient high-performance process capability, product quality restrictions, difficult chamber high temperature, etc., and achieve improvement Safety of use and performance of heat treatment furnaces, prevention of burnout or normal malfunction, and effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

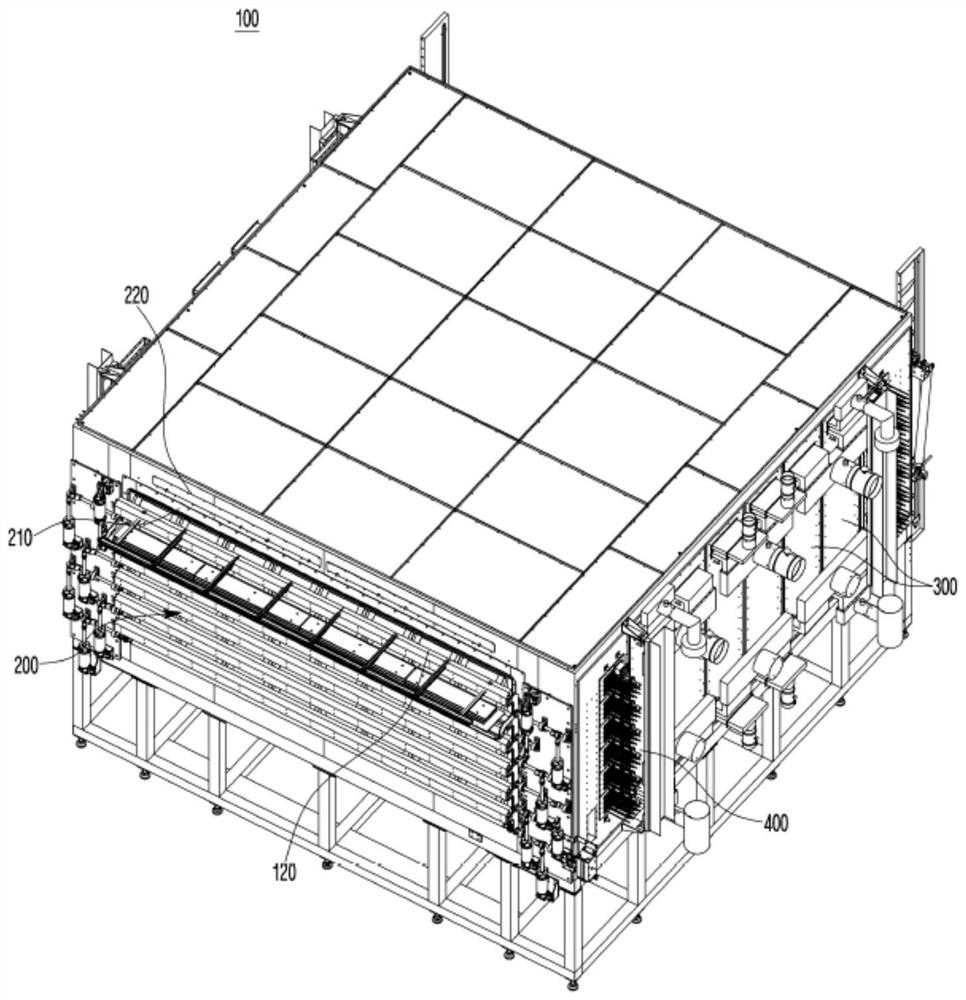

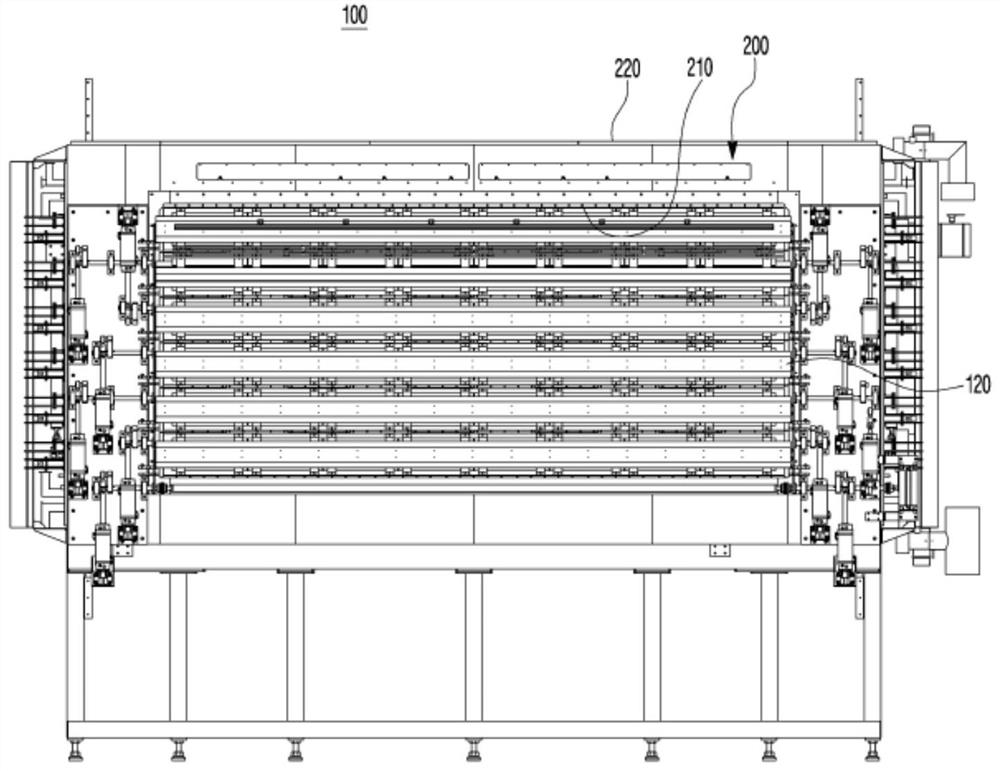

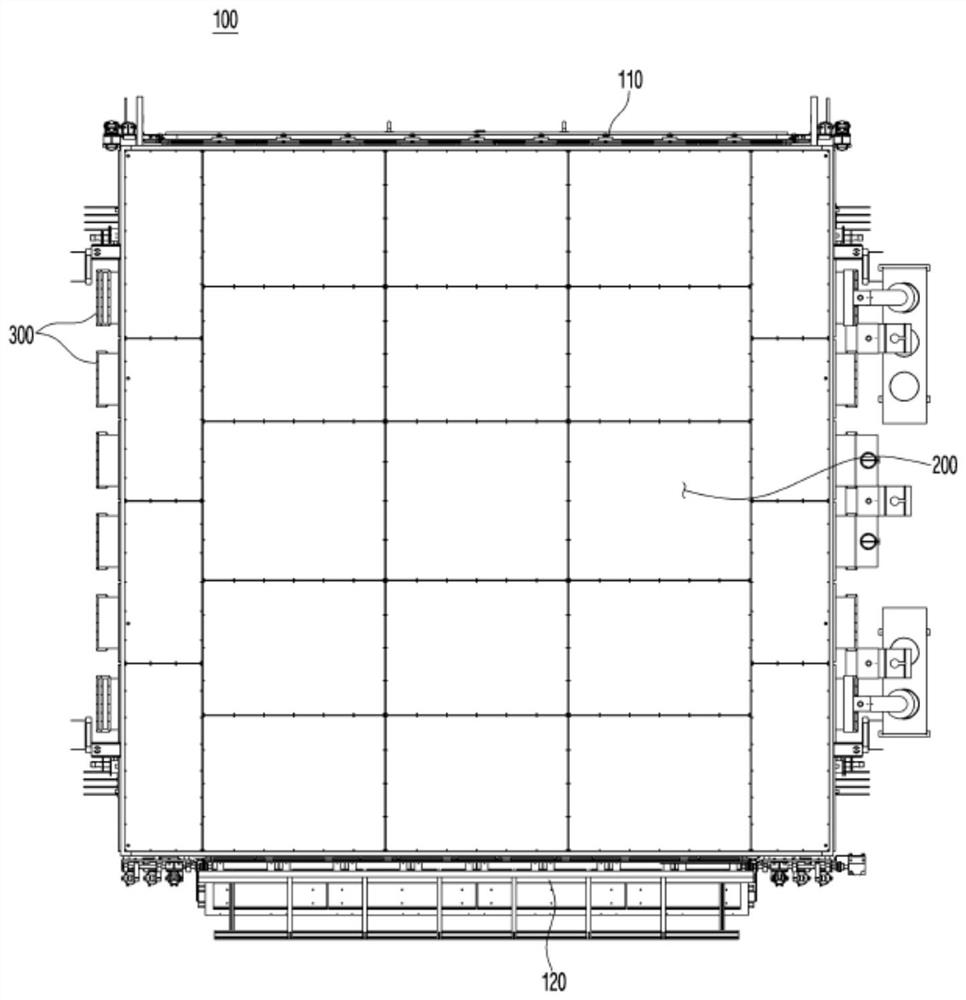

[0056] Hereinafter, the content of the cooling unit of the heat treatment furnace chamber according to the preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0057] Generally, the front side of the heat treatment furnace for heat treatment of substrates can have a shutter, and the rear side can have a furnace door, so that the substrates to be heat treated can be put into the preset tables in the chamber or the substrates after the heat treatment process can be removed from the chamber.

[0058]In addition, the heat treatment furnace has a chamber for accommodating a substrate to be heated or dried, and a heating body composed of a heater is installed in the chamber so that the substrate can be heated with heat generated from the heater or dried by evaporating moisture. In addition, although it varies depending on the configuration, generally the upper and lower parts of the heater are provided with upper / low...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap