Multi-channel multifunctional flow metering system

A flow metering and multi-channel technology, applied in volume flow ratio measurement, measurement flow/mass flow, temperature measurement of moving fluid, etc., can solve the problem of increased personnel costs and data error rate, low efficiency and accuracy, high error rate, etc. problems, to achieve the effect of improving the efficiency and convenience of measurement and monitoring, improving production efficiency, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Tests the flow of steam and condensate in steam pipes and calculates and displays the condensate mass as a percentage of the total fluid mass in the pipe.

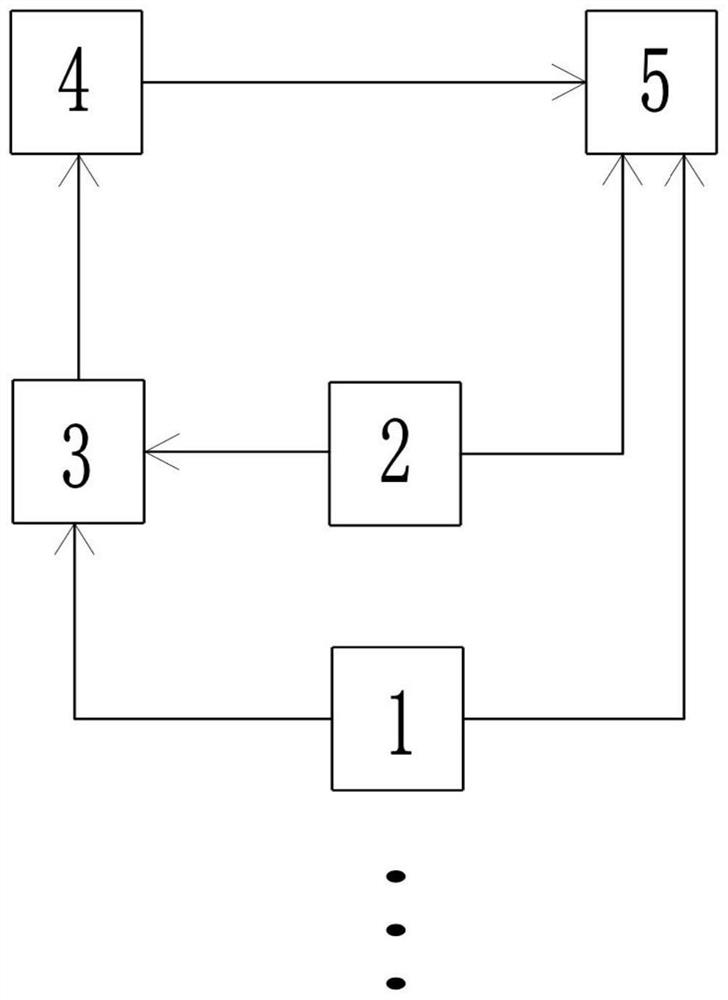

[0015] The flow detection unit 1 is installed on the branch pipe separating the condensed water from the steam pipe, detects the pressure, temperature and flow of the condensed water, and sends these signals to the multi-channel display unit 3 and the proportional calculation display unit 5; The flow detection unit 2 is installed on the steam pipeline after the condensed water is separated, and is located on the steam pipeline behind the branch pipe of the flow detection unit 1, and detects the pressure, temperature and steam flow in the steam pipeline after the condensed water is separated, and these The signal is delivered to the multi-channel display unit 3 and the proportional calculation display unit 5; the multi-channel display unit 3 displays the pressure, temperature, flow of condensed water and the steam pre...

Embodiment 2

[0017] Calculate and display the metering of multiple water supply pipes and the proportion of water volume of each channel.

[0018] The flow detection unit 1, the flow detection unit 2, ..., the flow detection unit N are respectively installed on N water supply pipes, measure the flow of each path, and simultaneously detect the pressure and temperature of each path of water as required, and send these signals Delivered to the multi-channel display unit 3 and the proportional calculation display unit 5; the multi-channel display unit 3 displays the flow, pressure, temperature, etc. of each road water, and sends each road flow signal to the sum calculation display unit 4; The summation calculation display unit 4 calculates the flow signals of N channels from the multi-channel display unit 3, finds the total value of the flow sum of the N channels, displays the total flow value and sends the signal to the proportional calculation display unit 5; The ratio calculation and displa...

Embodiment 3

[0021] Calculate and display the steam metering of multiple steam pipelines and the flow ratio of each channel. Implementation is similar to Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com