Styrene storage tank for ABS high rubber powder production

A technology of styrene and high rubber powder, which is applied in the direction of tank cars, transport passenger cars, railway car body parts, etc., can solve the problem of uneven cooling of styrene particles in storage, and improve the cooling effect, cooling uniformity and response speed Fast, thorough results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

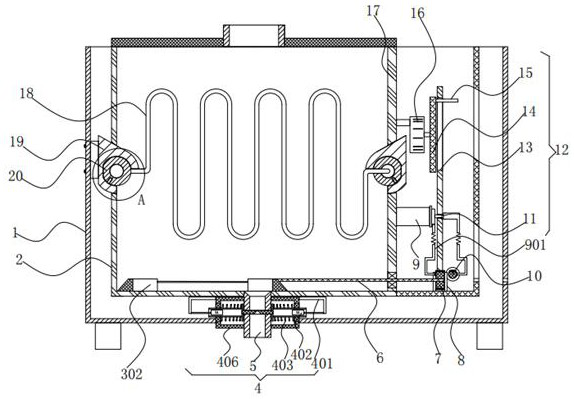

[0032] refer to Figure 1-4 , a styrene storage tank for the production of ABS high rubber powder, comprising an insulating casing 1 with a cavity inside and a rectangular parallelepiped structure as a whole, the inner wall of the insulating casing 1 is provided with an inner barrel 2 whose opening is upward, and the outer wall of the inner barrel 2 is in line with the Insulation material is filled between the heat preservation shells 1, and a vertical inner partition 17 is fixed on the bottom inner wall of the inner barrel 2 at a quarter position, and the inner partition 17 divides the inner wall of the inner barrel 2 into a storage chamber and a control chamber, And the middle of the bottom of the storage cavity is provided with a discharge mechanism 4, and the top of the discharge mechanism 4 is provided with a cooling pipe 18 in a coil-shaped structure. Both ends are fixed with inner slide tubes 20, the inner wall of the inner bucket 2 and the middle of the surface of the ...

Embodiment 2

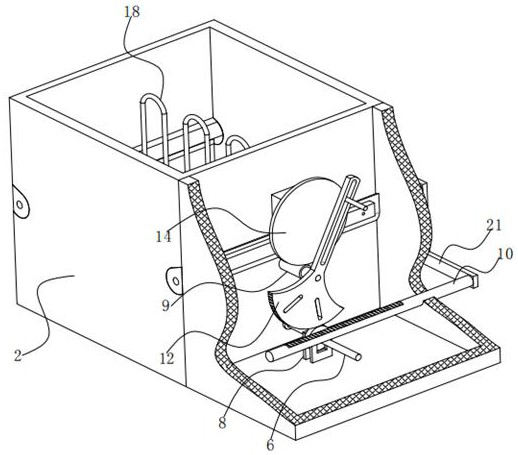

[0039] refer to Figure 5-6 , a styrene storage tank for ABS high rubber powder production. Compared with Embodiment 1, this embodiment also includes an inner barrel 2 which is a cylindrical inner barrel 201 with a cavity inside, and a bearing is embedded in the middle of the inner partition 17. The end of the cooling pipe 18 passes through the bearing and is sleeved with a driven pulley 23 on its outer wall, and the bottom inner wall of the cylindrical inner barrel 201 is rotatably connected with a transmission rod 232, and the outer wall of the transmission rod 232 is arranged in the storage chamber and fixed with a helical blade 24, The other end of the transmission rod 232 is respectively fixed with a driving pulley 231 and a driving motor, the driving pulley 231 and the driven pulley 23 form a transmission connection, and the side of the cylindrical inner barrel 201 away from the inner partition 17 is fixed with a cooling pipe 18 to form a slip ring connection. Condenser ...

Embodiment 3

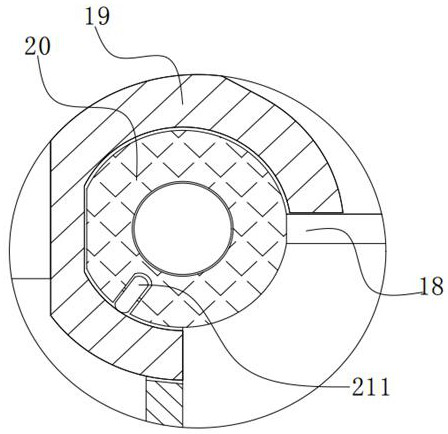

[0043] refer to Figure 7-8 , a styrene storage tank for the production of ABS high rubber powder. This implementation improves the internal structure of the cylindrical inner barrel 201 on the basis of the cylindrical inner barrel 201 with the same structure in Example 2. The improvement is that the cylindrical inner barrel 201 There is also a material-turning mechanism 25 inside, and the material-turning mechanism 25 includes two inner rings 251 parallel to each other and equal in size, between which two inner rings 251 are fixed with L-shaped pocket material plates 252 equidistant and symmetrically distributed. The outer wall of the ring 251 is provided with roller grooves 253 distributed equidistantly. The roller grooves 253 are provided with protruding rollers 254. The cooling pipe 18 inside the cylindrical inner barrel 201 is fixed and placed horizontally. The horizontal plate edge of the L-shaped pocket material plate 252 There are anti-slip convex ribs reserved at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com