Device capable of achieving single-piece separation on stacked glass fabric

A single-sheet separation and glass fiber cloth technology, which is applied in the directions of pile separation, packaging, and object separation, can solve the problems of inconvenient packaging, affecting work efficiency, and large labor force, and achieves high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

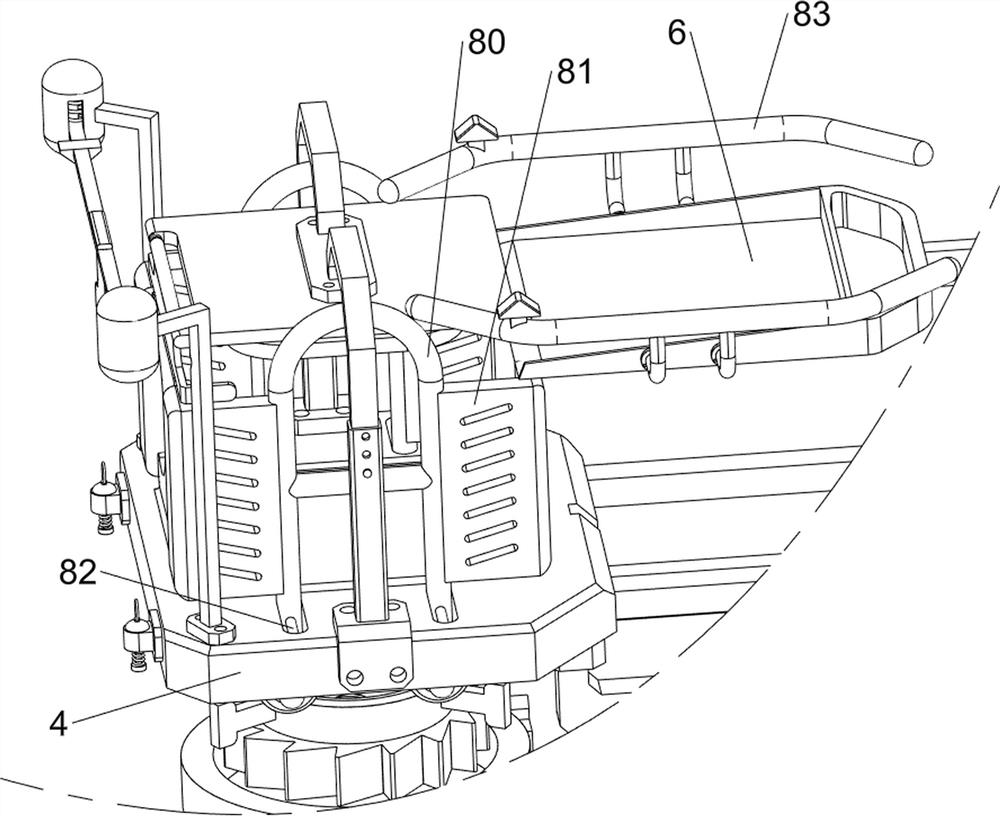

[0035] A device capable of separating sheets of stacked glass fiber cloth, such as Figure 1-6 As shown, it includes a base plate 1, a first support frame 2, an electric slide rail 3, a first support block 4, a push rod 5, a shovel 6, a lifting mechanism 7 and a clamping mechanism 8, and the top of the base plate 1 is symmetrically provided with a first The support frame 2, the first support block 4 is connected between the upper parts of the two first support frames 2, the electric slide rail 3 is arranged on the right side of the first support block 4, the electric slide rail 3 is connected with the bottom plate 1, and the electric slide rail 3 is on the right side The side sliding type is provided with a push rod 5, the top left side of the push rod 5 is provided with a shovel 6, the top of the base plate 1 is provided with a lifting mechanism 7, and the top of the first support block 4 is provided with a clamping mechanism 8.

[0036]When people need to separate the stacke...

Embodiment 2

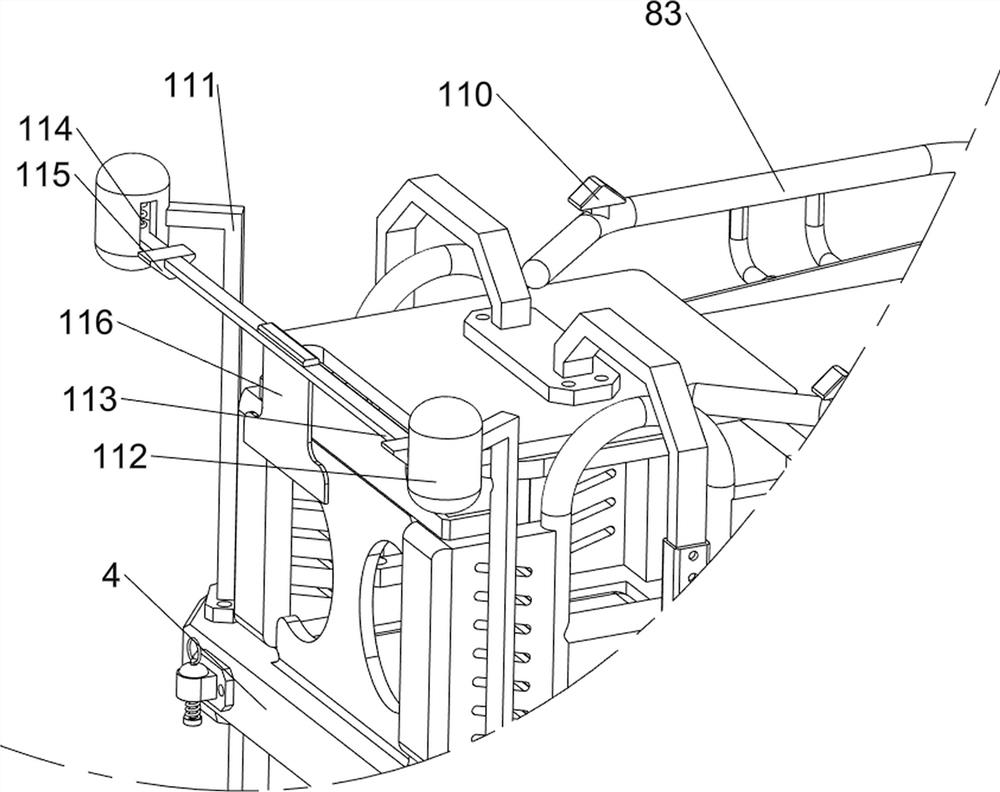

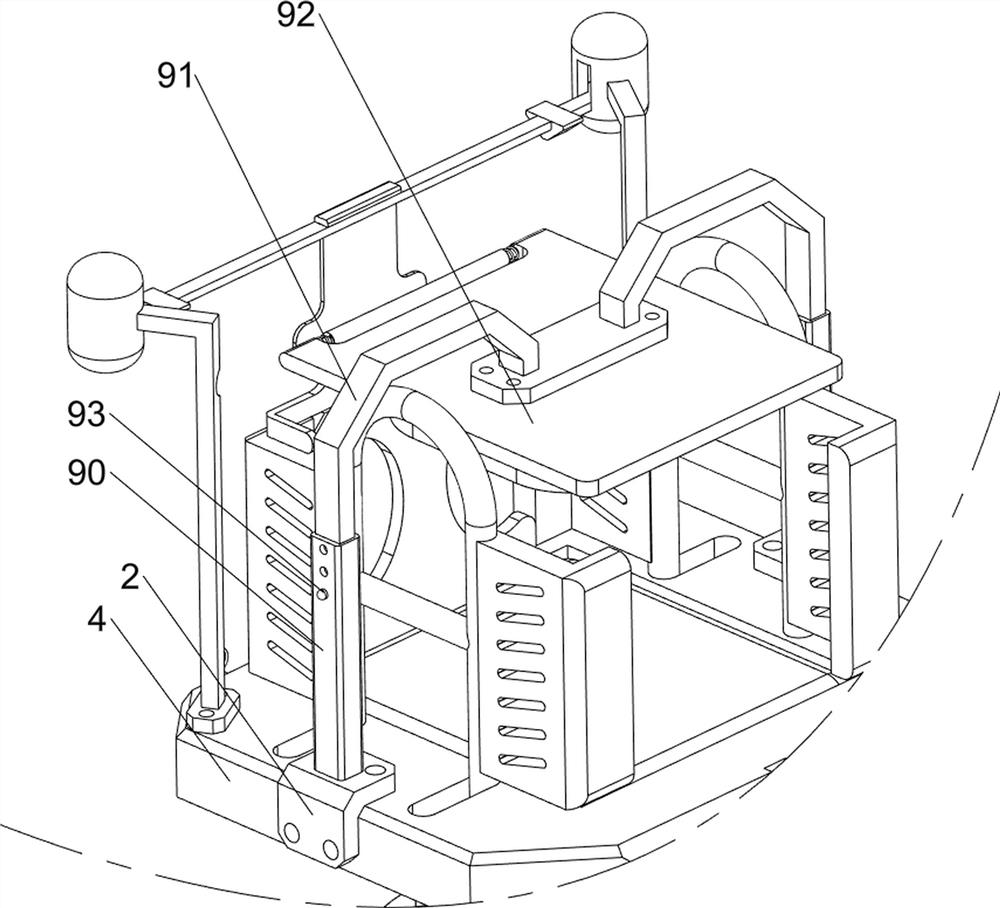

[0042] On the basis of Example 1, such as figure 1 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 As shown, an adjustment mechanism 9 is also included, and the adjustment mechanism 9 includes a sleeve 90, a first connecting rod 91, a second support plate 92, a button 93 and a second return spring 94, and the tops of the two first support frames 2 are provided with There are sleeves 90, the first connecting rods 91 are installed in the two sleeves 90, the second support plate 92 is connected between the bottoms of the two first connecting rods 91, and the lower sides of the two first connecting rods 91 are sliding A button 93 is provided, and a second return spring 94 is connected between the button 93 and the first connecting rod 91 on the same side. There are three adjustment slots on the outer sides of the upper parts of the two sleeves 90, and the button 93 can block the three on the same side. Adjustment slot.

[0043] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com