Drill rod disassembly and assembly auxiliary device and drilling equipment

A technology for auxiliary devices and drill pipes, which is applied to drilling equipment, drill pipes, and drill pipes. It can solve problems such as increased construction difficulty and risk factors, restrictions on single drill pipes, and height restrictions on guide columns, so as to facilitate alignment and connection. Reduce construction difficulty and risk factor, reduce the effect of accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

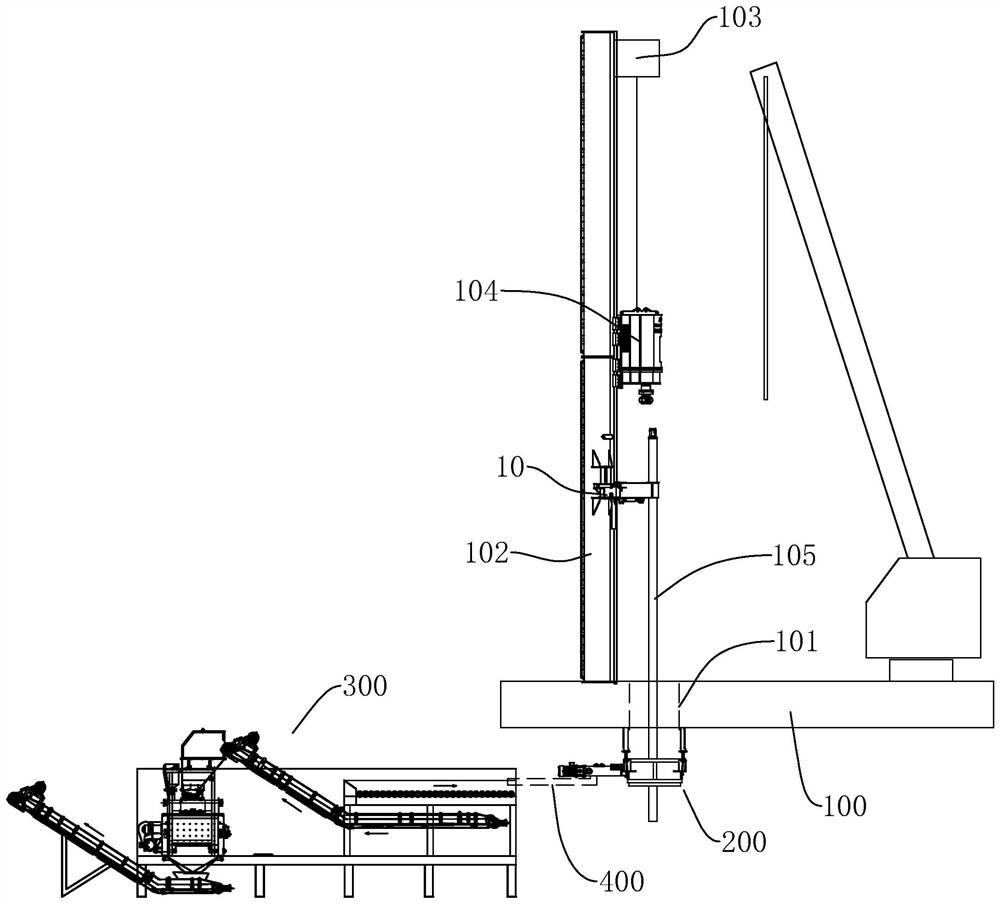

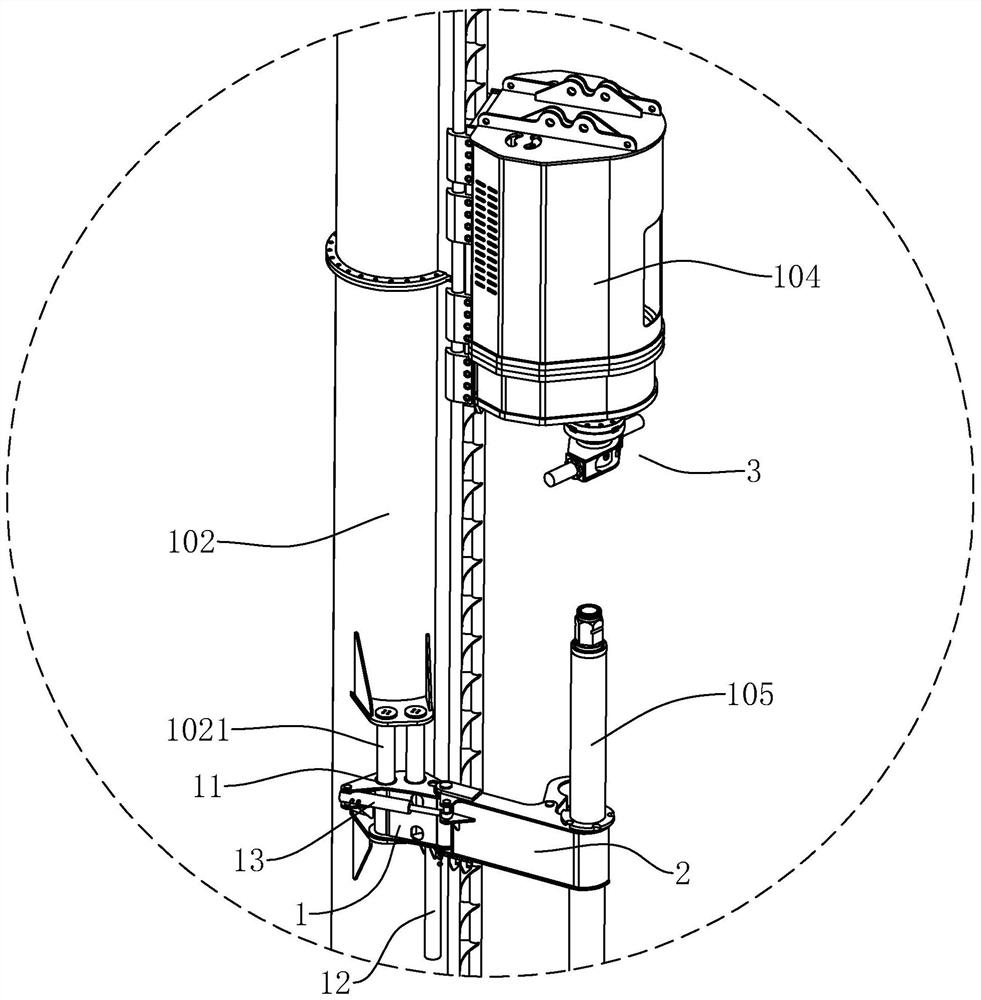

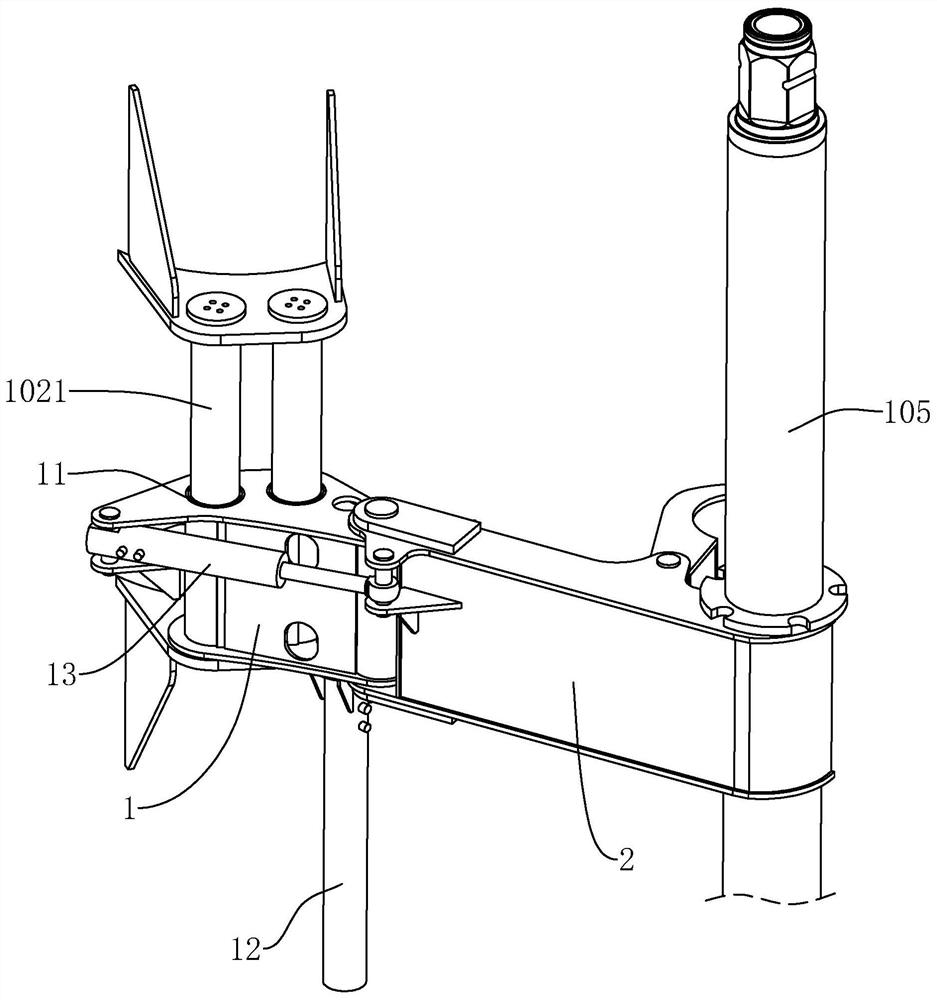

[0053] Such as figure 1 As shown, a kind of drilling equipment comprises frame 100, winch 103, drill pipe dismounting auxiliary device 10, muddy water conveying device 200 and muddy water mixing system 300, wherein frame 100 is equipped with vertically arranged guide post 102, guide post 102 is equipped with a power head 104, and the winch 103 controls the lifting and moving of the power head 104, and the power head 104 is equipped with a drill pipe 105.

[0054] During use, the crane lifts the drill pipe 105 to the drill pipe dismounting auxiliary device 10, the drill pipe dismounting auxiliary device 10 will grab the drill pipe 105, and move the drill pipe 105 to the bottom of the power head 104, and then put the drill pipe 105 It is matched with the power head 104 and installed; then the power head 104 drives the drill pipe 105 to rotate and move down to complete a drilling; after a drilling is completed, the installation between the power head 104 and the first drill pipe ...

Embodiment 2

[0085] Such as Figure 11 As shown, the following settings are made on the basis of Embodiment 1. The auxiliary device 10 for drilling pipe disassembly and assembly also includes a monitoring component 106. The monitoring component 106 can be installed on the body of the power head 104, and the monitoring component 106 can also be installed on the guide column 102. Above, the monitoring component 106 may be a monitoring device such as a camera, an infrared distance measuring device, or the like.

[0086] The monitoring component 106 is used to monitor the cooperation between the drill pipe 105 and the power head 104, which is convenient for the operator to remotely monitor the cooperation between the drill pipe 105 and the power head 104, so as to adjust the position of the drill pipe 105 or the power head 104 according to the cooperation , thereby ensuring the accuracy of the drill rod 105 dismounting, and relatively safe.

Embodiment 3

[0088] Such as Figure 12 As shown, the difference from Embodiment 1 is that the part of the fixed claw part 21 away from its own claw mouth is slidably connected with the mounting base 1, and the sliding direction of the fixed claw part 21 is horizontally close to or away from the vertical direction of the power head 104. Set to the path; the first drive assembly 13 is a linear reciprocating drive mechanism such as an air cylinder, a hydraulic cylinder, and a motor screw drive structure. One end of the first drive assembly 13 is fixedly connected to the mounting base 1, and the other end of the first drive assembly 13 is fixed to the mounting base 1. The claw portion 21 is fixedly connected, that is, the first driving assembly 13 drives the clamping claw 2 to move by horizontal sliding, so as to realize the position adjustment of the drill rod 105 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com