Novel method for adjusting intensity of X-rays irradiating on surface of object to be measured

A technology of surface strength and object to be measured, applied in measurement devices, using wave/particle radiation, instruments, etc., can solve problems such as errors, and achieve the effect of convenient operation, simple structure, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

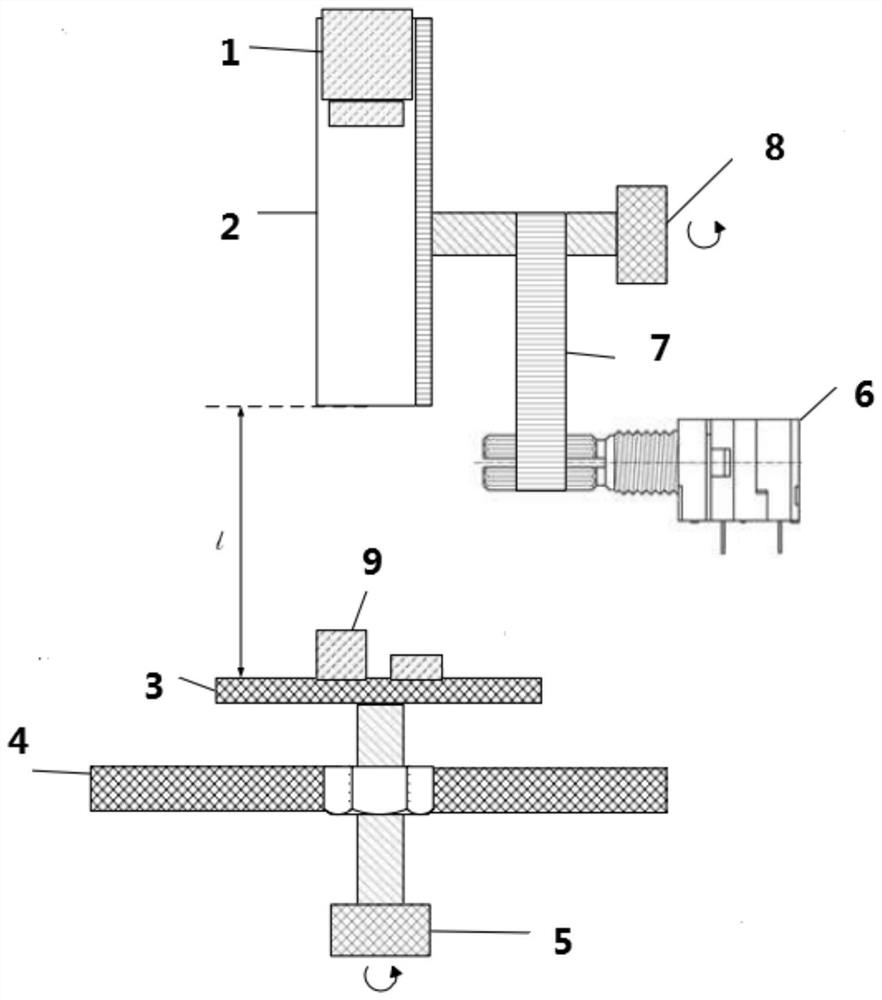

[0031] Embodiment 1: A new adjustment method for X-ray irradiation on the surface intensity of the object to be measured, such as figure 1 Shown, including the following working steps:

[0032] Step 1: Place an ultra-thin standard sheet on the object-to-be-tested stage 3, adjust the height adjustment knob 8 of the collimator sleeve, fix the height adjustment knob 8 of the collimator sleeve to a certain position, and adjust the precision adjustable potentiometer 6 It is connected with the height adjustment knob 8 of the collimator sleeve through the toothed transmission belt 7, rotates together with the height adjustment knob 8 of the collimator sleeve, and reads the resistance value from the precision adjustable potentiometer 6, which can be converted into the object to be measured Subtract the thickness of the ultra-thin standard sheet from the distance between the stage 3 and the collimator sleeve 2 to obtain the distance l between the surface of the standard sheet and the c...

Embodiment 2

[0038] Embodiment two: a new method for adjusting the intensity of X-ray irradiation on the surface of the object to be measured, such as figure 1 Shown, including the following working steps:

[0039] Step 1: Place an ultra-thin standard sheet on the object-to-be-tested stage 3, adjust the height adjustment knob 8 of the collimator sleeve, fix the height adjustment knob 8 of the collimator sleeve to a certain position, and adjust the precision adjustable potentiometer 6 It is connected with the height adjustment knob 8 of the collimator sleeve through the toothed transmission belt 7, rotates together with the height adjustment knob 8 of the collimator sleeve, and reads the resistance value from the precision adjustable potentiometer 6, which can be converted into the object to be measured Subtract the thickness of the ultra-thin standard sheet from the distance between the stage 3 and the collimator sleeve 2 to obtain the distance l between the surface of the standard sheet a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com