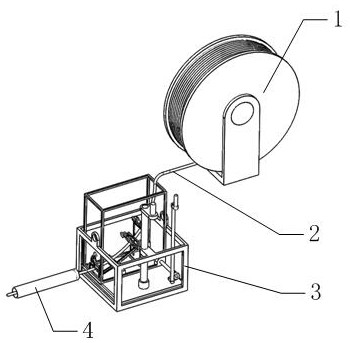

Cable laying mechanism in power construction

A technology for cable laying and electric power construction, which is applied to cable laying equipment, cable installation in underground pipelines, cable installation, etc., can solve problems such as large space occupation, difficulty in penetration, and failure of conductive pads, and achieve low labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

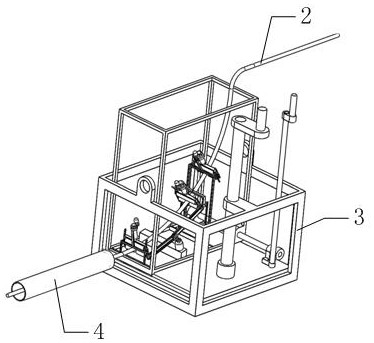

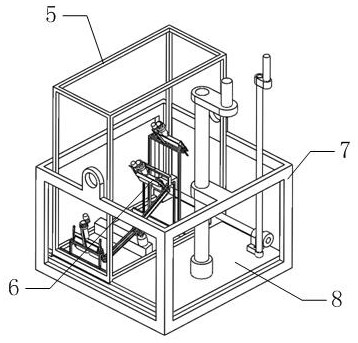

[0092] Embodiment: When using the equipment designed by the present invention, when in use, the laying mechanism 3 is first placed in the well, and then the clamping conveying mechanism and the clamping guide mechanism 13 are adjusted by the first rocker 10 and the second rocker 14 position; after the position is determined, pull out the cable 2 from the winding roller 1 on the upper side of the ground, insert it into the clamping guide mechanism 13, and then manually install the guide mechanism 42 on the cable 2 one by one. 42, first adjust the length of the adjustable-length support rod according to the inner diameter of the cable pipe 4 and the model of the guide mechanism 42, so that the support wheel 62 is in contact with the inner wall of the cable pipe 4; when adjusting, manually rotate Adjust the threaded sleeve 65 so that the adjustable threaded sleeve 65 drives the telescopic screw rod 63 to elongate or shorten relative to the fixed sleeve 64 under the action of threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com