Silkworm cocoon pretreatment equipment and pretreatment process thereof

A pretreatment and silkworm cocoon technology is applied in the silkworm cocoon pretreatment process. , In the field of silkworm cocoon pretreatment equipment, it can solve the problems of inability to distinguish and sort silkworm cocoons, and achieve the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

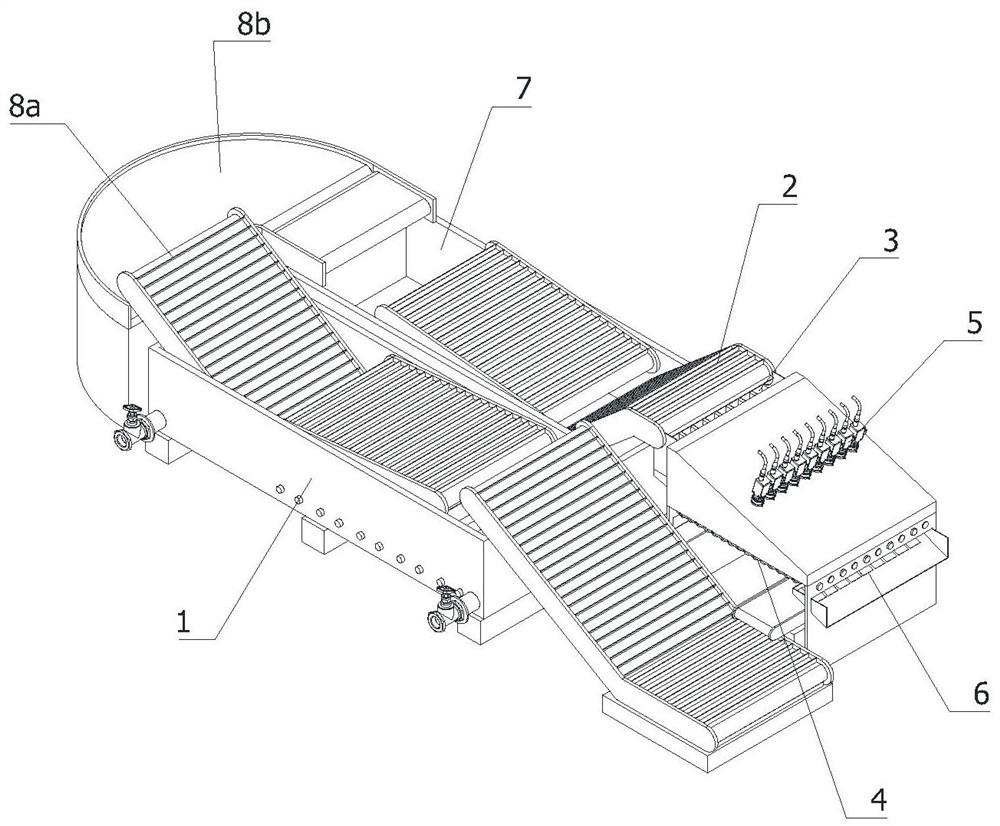

[0050] In order to solve the technical problem that the existing cocoon pretreatment equipment cannot effectively detect and screen the incompletely degummed cocoons, such as figure 1 As shown, the following preferred technical solutions are provided:

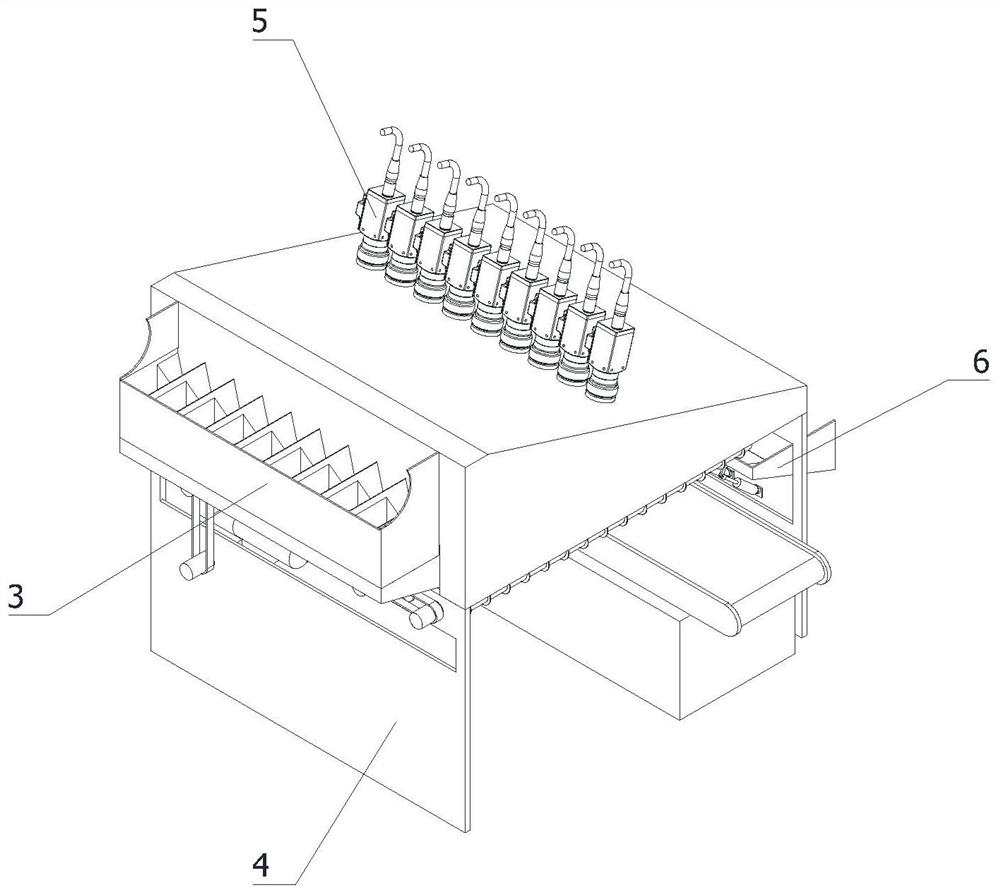

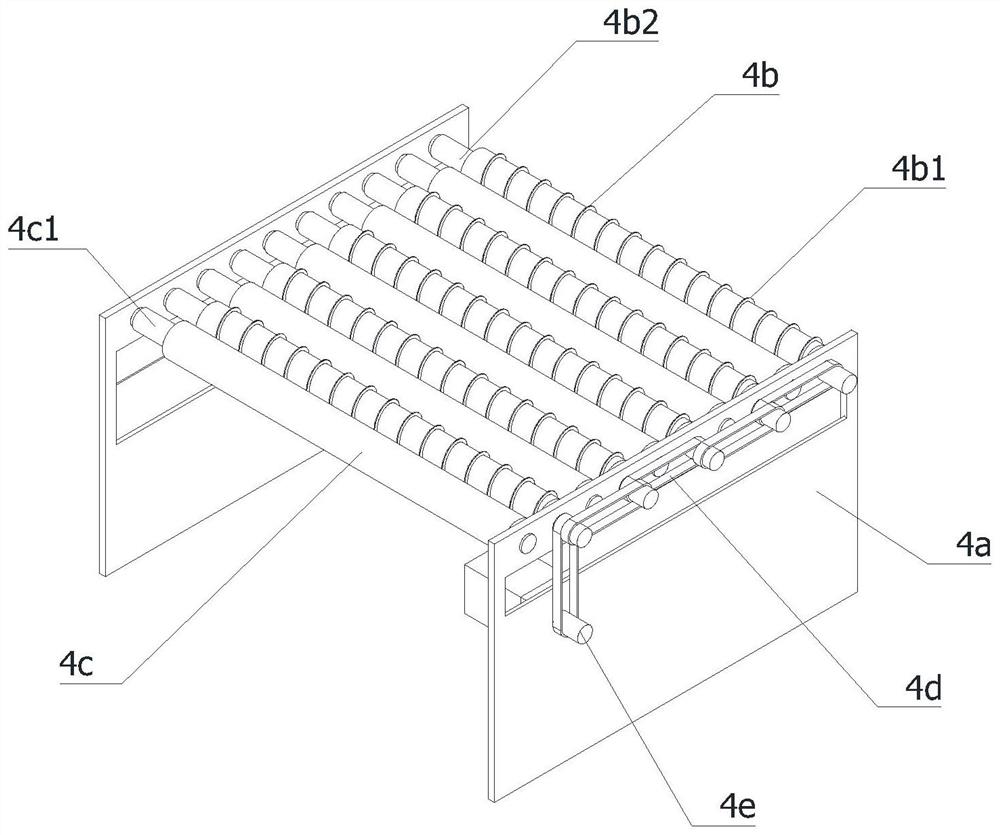

[0051] A kind of silkworm cocoon pretreatment equipment, comprising, degumming tank 1 and first mesh chain partition conveyor 2, the first mesh chain partition conveyor 2 is obliquely arranged in the degumming pond 1, and the first mesh chain partition The discharge end of the conveyor 2 is higher than its feed end and extends to the outside of the degumming pool 1; it also includes a material distribution mechanism 3, which is arranged at the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com