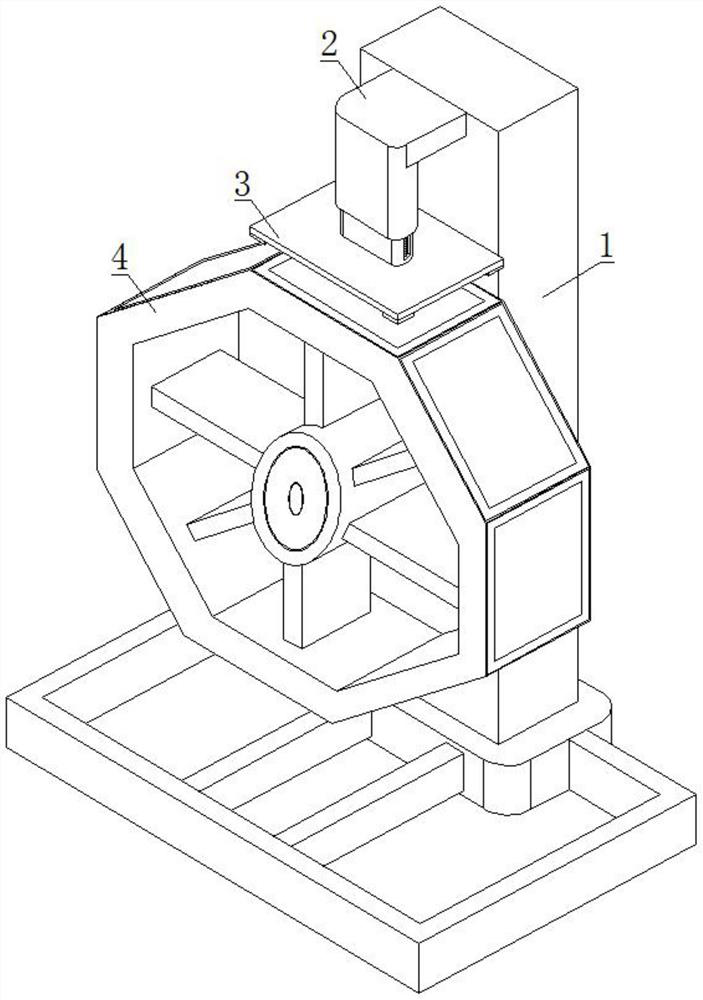

Solder mask silk printing device for high-density circuit board production and implementation method thereof

A screen printing device and circuit board technology, applied in screen printing, screen printing machines, printing, etc., can solve the problems of limited scraping range, cumbersome operation, and affecting the quality of circuit board screen printing, etc., and achieve the effect of convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

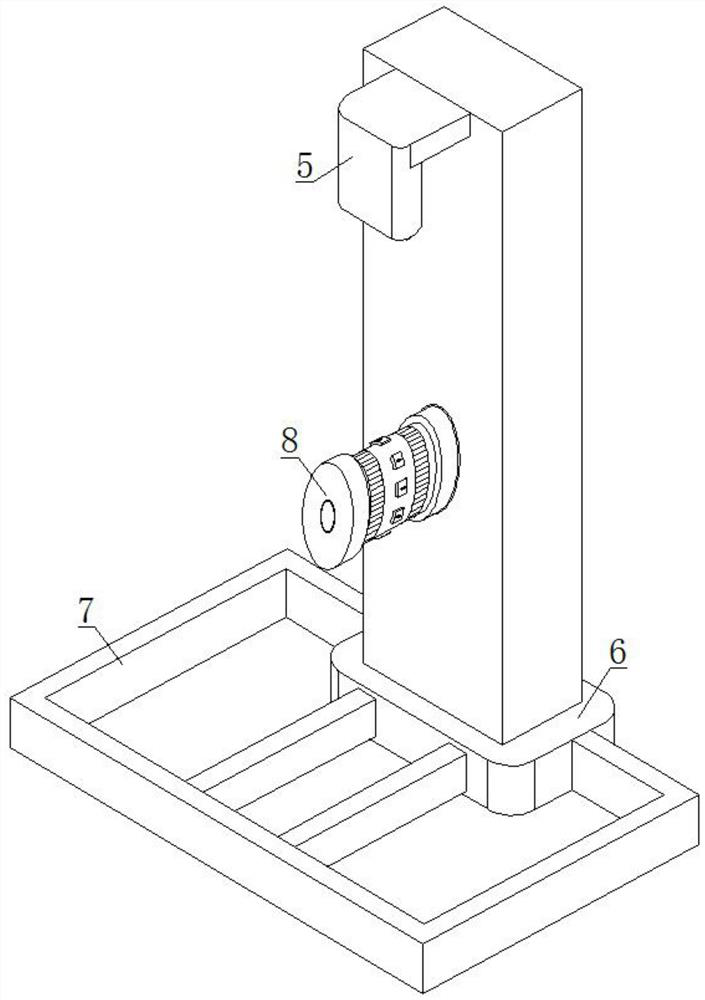

Method used

Image

Examples

Embodiment approach , 1 Embodiment approach

[0043] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, a method for implementing a solder resist screen printing device for high-density circuit board production, including the following steps:

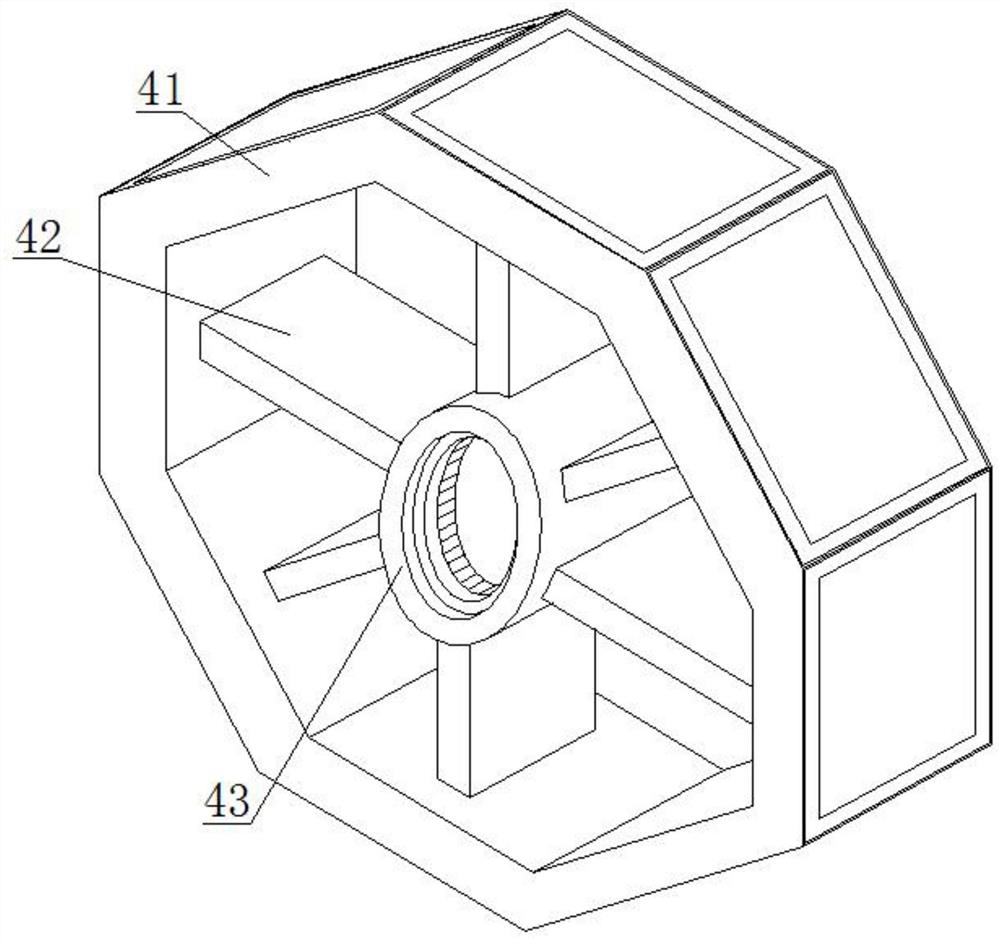

[0044] Step 1: Start the telescopic rod 4133, turn the connecting rod 4113 to move along the sliding groove 4131, and as the rotating connecting rod 4113 tilts up, use the return spring 4123 to make the limiting plate 412 drive the pressing plate 411 out of the receiving groove 413, and One end of the pressing plate 411 is limited by the hinge 4111, the other end of the pressing plate 411 is tilted up, the circuit board is placed in the limit slot 4121, and then the telescopic rod 4133 is pushed to drive the rotating connecting rod 4113 to the receiving groove The inner bottom surfaces of 413 are moved closer together, so that the pressing plate 411 and the limiting plate 412 are re-accommodated into the receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com