Vertical unbonded prestressed anti-seismic reinforcing structure for masonry building

A reinforced structure, non-bonded technology, applied in the direction of building components, buildings, building types, etc., can solve the problems of the reduction of the concealment of the anti-seismic fixing mechanism, the impact on the appearance and internal parts of the house, and the strong destructiveness of the anti-seismic reinforcement method. Elasticity, simple construction, structurally destructive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

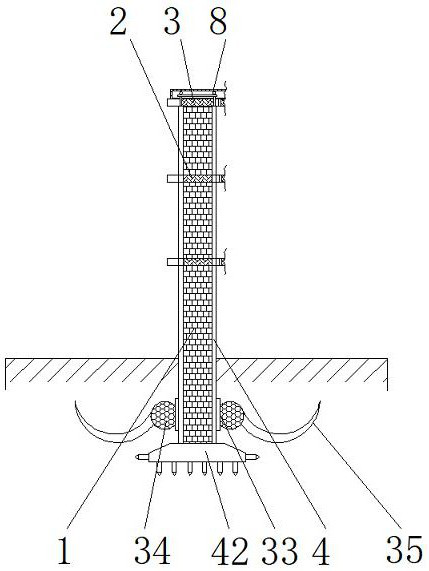

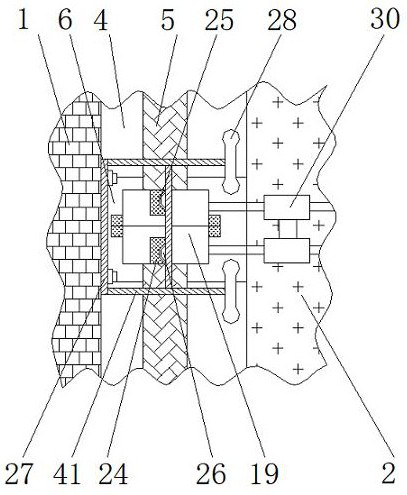

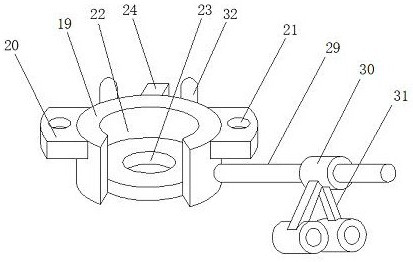

[0030] Such as Figure 1-6 As shown, the vertical unbonded prestressed anti-seismic strengthening structure of a masonry building according to an embodiment of the present invention includes a wall 1 on which a multi-layer floor 2 is arranged, and the top of the wall 1 is provided with Roof panel 3, the top of the roof panel 3 is provided with a number of evenly distributed hollow reinforcing plates 8, and the top of the hollow reinforcing plates 8 is provided with symmetrically arranged fixing blocks 9, and the fixing blocks 9 of the two groups are all reinforced by The strips 10 are connected, and the inside and outside of the wall 1 are provided with a number of evenly distributed vertical installation grooves 4, and a number of evenly distributed seismic reinforcement ribs 5 are installed in the vertical installation grooves 4, and the topmost The anti-seismic reinforcing ribs 5 all extend into the hollow reinforcing plate 8 and run through the reinforcing bar 10, and the ...

Embodiment 2

[0032] Such as Figure 1-6As shown, the vertical unbonded prestressed anti-seismic strengthening structure of a masonry building according to an embodiment of the present invention includes a wall 1 on which a multi-layer floor 2 is arranged, and the top of the wall 1 is provided with Roof panel 3, the top of the roof panel 3 is provided with a number of evenly distributed hollow reinforcing plates 8, and the tops of the hollow reinforcing plates 8 are provided with symmetrically arranged fixing blocks 9, and the fixing blocks 9 of the two groups are all reinforced by The strips 10 are connected, and the inside and outside of the wall 1 are provided with a number of evenly distributed vertical installation grooves 4, and a number of evenly distributed seismic reinforcement ribs 5 are installed in the vertical installation grooves 4, and the topmost The anti-seismic reinforcing ribs 5 all extend into the hollow reinforcing plate 8 and run through the reinforcing bar 10, and the...

Embodiment 3

[0034] Such as Figure 1-6 As shown, the vertical unbonded prestressed anti-seismic strengthening structure of a masonry building according to an embodiment of the present invention includes a wall 1 on which a multi-layer floor 2 is arranged, and the top of the wall 1 is provided with Roof panel 3, the top of the roof panel 3 is provided with a number of evenly distributed hollow reinforcing plates 8, and the tops of the hollow reinforcing plates 8 are provided with symmetrically arranged fixing blocks 9, and the fixing blocks 9 of the two groups are all reinforced by The strips 10 are connected, and the inside and outside of the wall 1 are provided with a number of evenly distributed vertical installation grooves 4, and a number of evenly distributed seismic reinforcement ribs 5 are installed in the vertical installation grooves 4, and the topmost The anti-seismic reinforcing ribs 5 all extend into the hollow reinforcing plate 8 and run through the reinforcing bar 10, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com