Horizontal pushing type gear shifting mechanism and system

A shift mechanism, flat-push technology, applied in mechanical equipment, components with teeth, belts/chains/gears, etc., can solve the problems of mechanical wear, complex structure, affecting performance, etc., to achieve long service life, simplified Structure, enhance the effect of lightweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

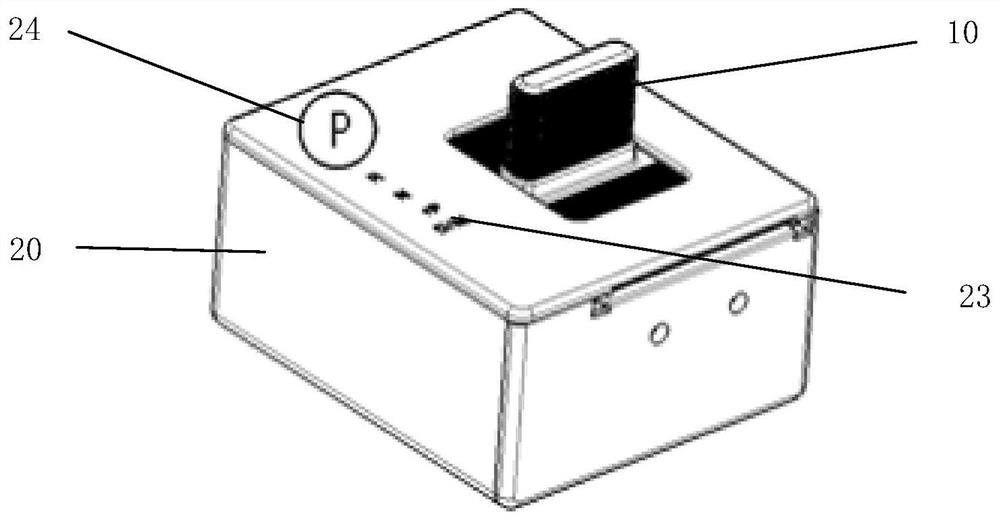

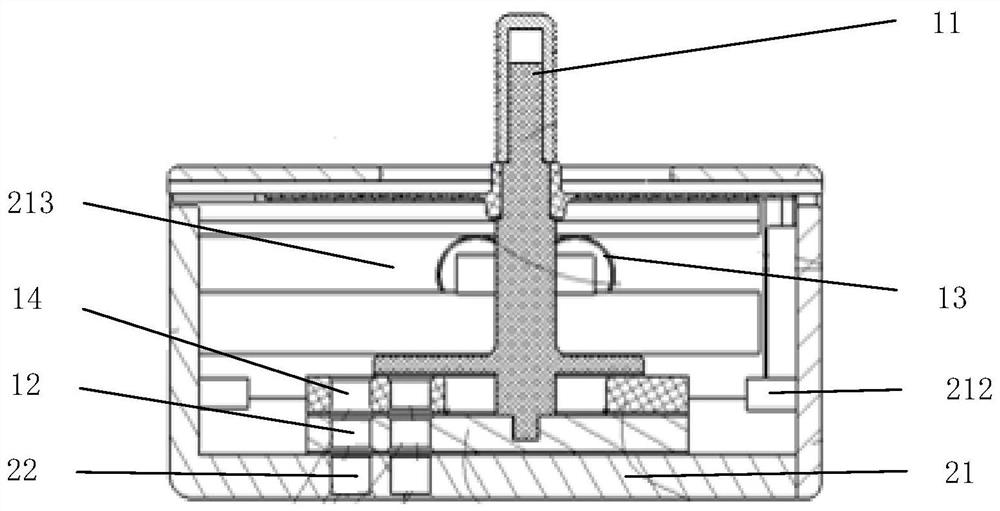

[0029] Please refer to Figure 1 to Figure 7 , the first embodiment of the present invention is a flat-push shift mechanism for shift-by-wire vehicles, including a shift lever assembly 10 and a base assembly 20 . The shift rod assembly 10 includes a rod body 11, a bearing group 13, a first magnetic element 12 and a third magnetic element 14 fixed on the rod body 11, and the base assembly 20 includes a base body 21, a second magnetic element fixed on the base body 21 Magnetic element 22, and gear display device 23.

[0030] The bearing set 13 includes at least one bearing, and the base body 21 is provided with a limiting groove 213 , and the bearing is installed in the limiting groove 213 with an interference fit. The inner ring of the bearing is fixed on the rod body 11, the outer ring of the bearing is in contact with the seat body 21, the bearing group 13 is used to make the shift lever assembly 10 slide on the base assembly 20, and the limit groove 213 is used to make the ...

no. 2 example

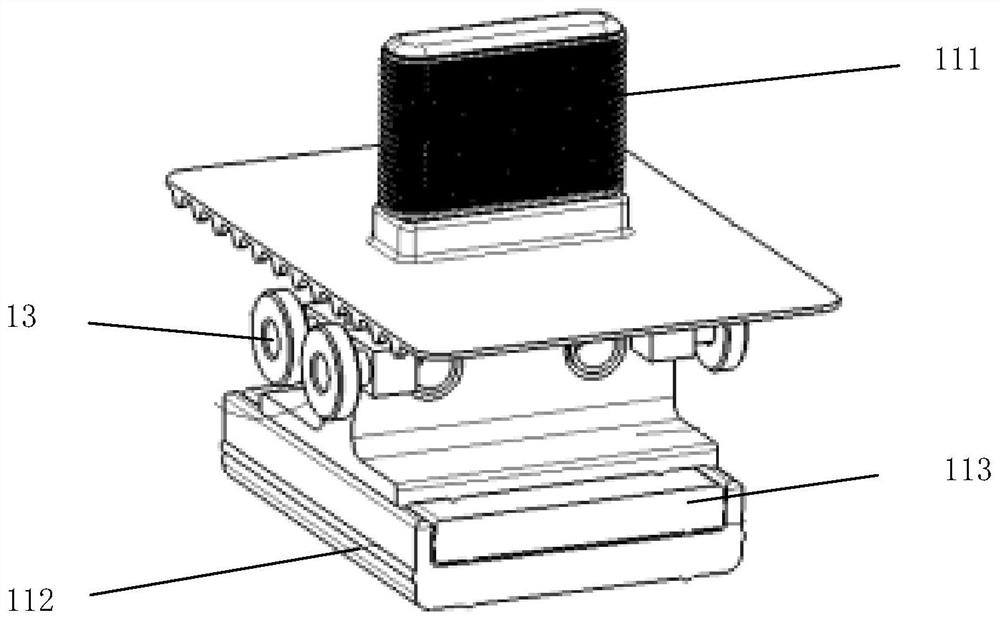

[0047] Please refer to Figure 8 to Figure 10 The difference between the second embodiment of the present invention, a flat-push shift mechanism, and the above-mentioned first embodiment is that in this embodiment, the rod body 11 only includes a handle 111 and a first sliding piece 112 fixedly connected to the end of the handle 111 , the moving position includes the front first position and the rear first position.

[0048] Other parts such as the bearing group 13 and the detection device are consistent with the first embodiment. The polarity of the first magnetic element 12 is opposite to that of the second magnetic element 22 , and the shift lever assembly 10 is located at the initial position under the action of the attractive force of the first magnetic element 12 and the second magnetic element 22 . The first sliding piece 112 can slide forward and backward in the base assembly 20 when the handle 111 is pushed by an external force, and can reach the first front position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com