Gas storage device for carbon dioxide oil displacement

A carbon dioxide and gas storage device technology, applied in fixed-capacity gas storage tanks, climate sustainability, other gas emission reduction technologies, etc., can solve problems affecting the service life of gas storage devices, increasing costs, and affecting the strength of storage tank steel. , to achieve the effect of unaffected steel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

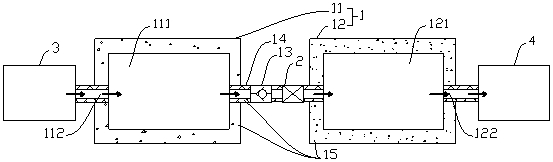

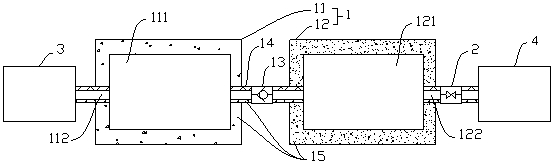

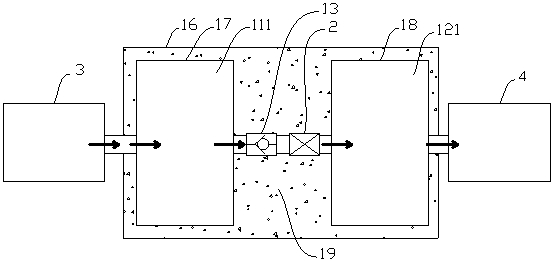

[0040] Such as Figure 1 to Figure 4 As shown, the present invention provides a gas storage device for carbon dioxide flooding, including a storage tank 1, the storage tank 1 includes a first tank body 11 with a first storage cavity 111 and a second tank body with a second storage cavity 121 12. There is a first valve 13 between the first storage chamber 111 and the second storage chamber 121 to control the on-off of the two. The first tank body 11 is provided with a fluid inlet 112 communicating with the first storage chamber 111. The fluid inlet 112 The second tank body 12 is provided with a fluid outlet 122 communicating with the second storage chamber 121, and the fluid outlet 122 communicates with the injection device 4 arranged outside the storage tank 1 , a gas storage device for carbon dioxide flooding is also provided with a pressure regulating device 2, by means of the pressure regulating device 2, the pressure in the second storage chamber 121 can be closer to that ...

Embodiment approach 1

[0047] Implementation mode one: if figure 1 and image 3 As shown, the pressure regulating device 2 is a supercharger arranged between the first storage chamber 111 and the second storage chamber 121 , and the supercharger is connected in series with the first valve 13 .

[0048] In this embodiment, a supercharger is set between the first storage chamber 111 and the second storage chamber 121 as the pressure regulating device 2, and the supercharger cooperates with the first valve 13 to form a The one-way pressurization device, on the one hand, the action force of the supercharger is fast, which can quickly increase the pressure of carbon dioxide between the first storage chamber 111 and the second storage chamber 121, greatly shortening the pressurization process, and further reducing The length of the idle period during which the injection device 4 starts. On the other hand, in the prior art, a supercharging device is added at the gas outlet of the gas storage device. Afte...

Embodiment approach 2

[0050] Implementation mode two: if figure 2 and Figure 4 As shown, the pressure regulating device 2 is a back pressure valve arranged between the second storage chamber 121 and the injection device 4. The back pressure valve is provided with a pressure value close to the pressure at the inlet end of the injection device 4. The second storage chamber 121 When the pressure is greater than or equal to the pressure value, the back pressure valve is opened to connect the second storage chamber 121 with the injection device 4 .

[0051] A back pressure valve is set between the second storage chamber 121 and the injection device 4 as the pressure regulating device 2, which is different from Embodiment 1. In this embodiment, the pressure regulating device 2 is arranged downstream of the second storage chamber 121, and the back pressure valve is set There is a pressure value close to the pressure at the inlet of the injection device 4. When the carbon dioxide in the first storage ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com