Artillery barrel rifling inner diameter measuring system and method

A technology for artillery barrels and measurement systems, which is applied in the direction of measuring devices, instruments, and optical devices, and can solve the problems of difficult access to measuring instruments, low precision, and difficulty in observation by human eyes, so as to eliminate processing and installation errors and improve measurement accuracy. Accuracy, the effect of small probe structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

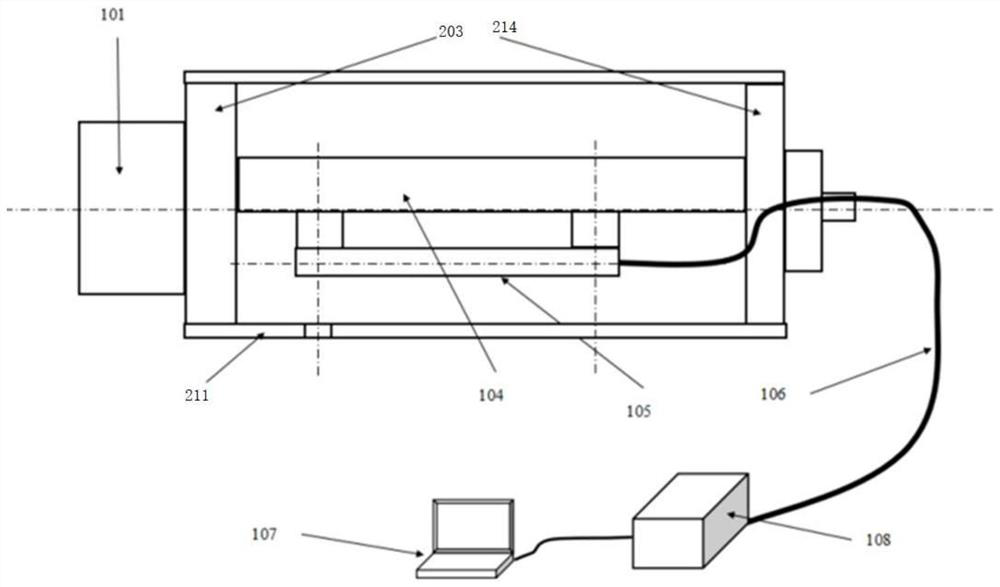

[0028] Such as figure 1 As shown, a system for measuring the inner diameter of the gun barrel rifling provided in this embodiment includes a measuring vehicle unit, a laser displacement sensor controller 108, and a control computer 107. The measuring vehicle unit communicates with the laser displacement sensor controller 108 through a probe optical cable 106 connected, the laser displacement sensor controller 108 is connected with the control computer 107;

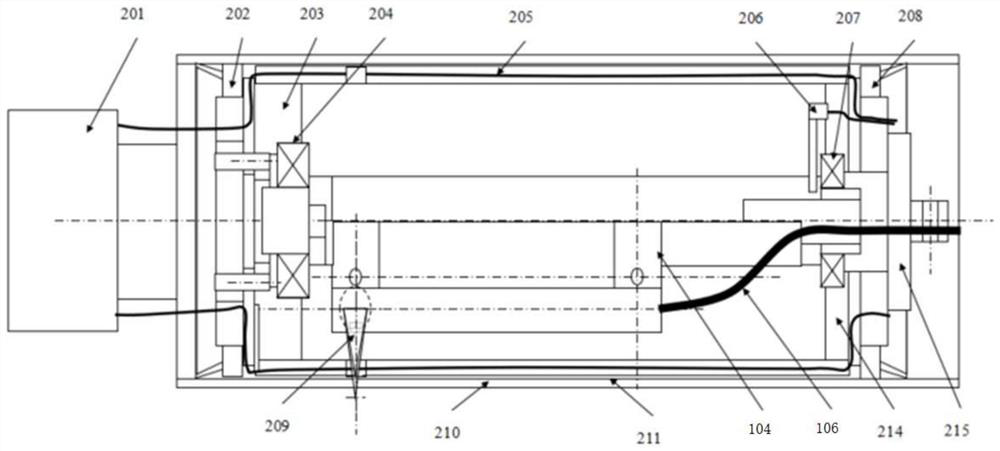

[0029] The measuring car unit includes a motor unit 101, a measuring car shell 211, a rotating bracket 104, a laser displacement sensor probe 105, a front motor flange 203, and a rear motor flange 214. The left end and the right end of the measuring car shell 11 are respectively provided with the The front motor flange 203, the rear motor flange 214, the front motor flange 203 and the motor unit 101, the rotating bracket 104 is arranged on the front motor flange 203, the rear motor flange 214 and is connected in rotation, ...

Embodiment 2

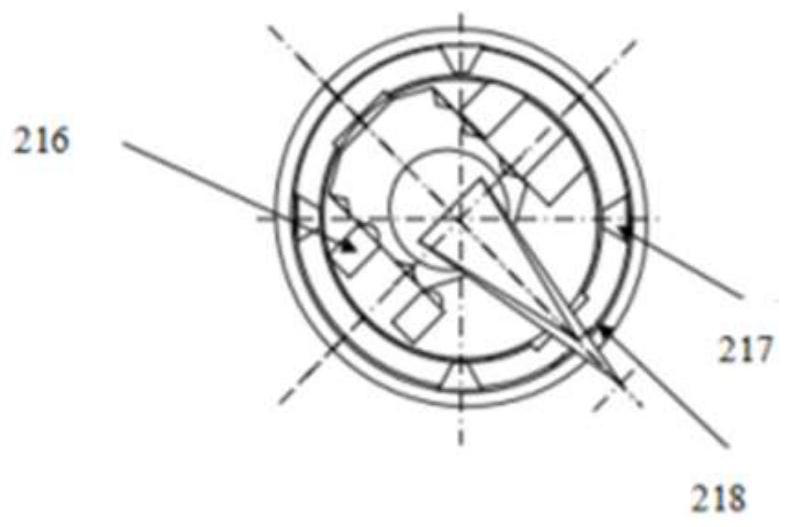

[0032] Such as Figure 2-4 As shown, in this embodiment, the rotating bracket 104 is connected to the laser displacement sensor probe 105 through a positioning bead structure, and the position of the laser displacement sensor probe 105 can be adjusted by adjusting the positioning bead structure. When measuring gun barrels of different calibers, the fixed position of the laser displacement sensor probe 105 is switched by rotating the positioning bead structure on the bracket 104 according to the size of the measured caliber.

[0033] Wherein, the positioning bead structure can adopt known technology.

[0034] In addition, after the measuring vehicle unit is installed into the barrel of the gun to be tested, under the centering action of the front and rear centering claws, the axis of the overall system is coaxial with the axis of the barrel, and the longitudinal axis of the measuring vehicle is perpendicular to the axis of the barrel. When in use, the front centering claw 202 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com