Portable 3D printing ceramic slurry filter

A technology of 3D printing and ceramic slurry, which is applied in the direction of fixed filter element filter, filter separation, filter circuit, etc., can solve the problems of bulky filter device, difficult operation, failure to realize frame protection and convenient movement, and achieve detachable The effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

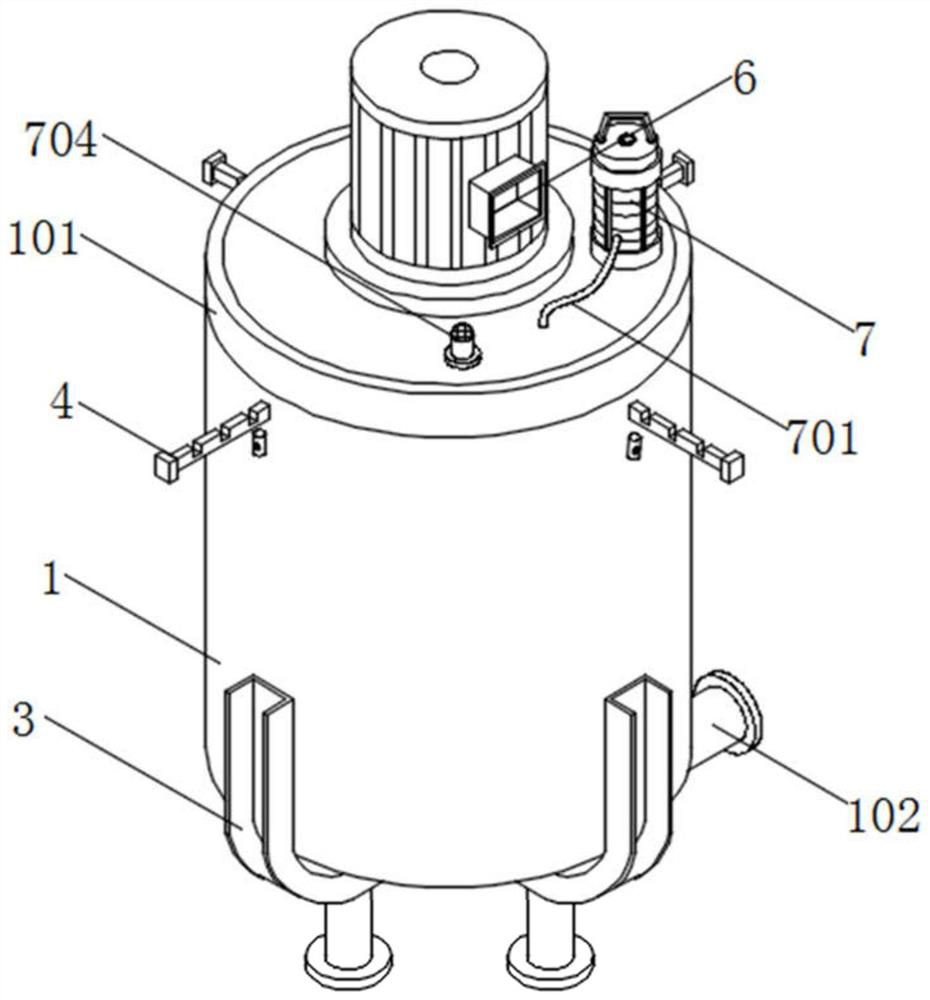

[0046] see figure 1 with Figure 9 , an embodiment provided by the present invention: a portable ceramic slurry filter for 3D printing, including a filter cylinder 1 and a booster pump 7, the top of the filter cylinder 1 is sealed with a sealing top cover 101, and the sealing top cover The top of 101 is equipped with booster pump 7;

[0047] The output end of the pressurizing pump 7 is connected with an air delivery pipe 701, the tail end of the air delivery pipe 701 extends into the inside of the filter cylinder 1, the bottom surface of the sealing top cover 101 is equipped with equidistantly arranged circular rings, and the pipe body of the air delivery pipe 701 Passing through the inside of the ring, the surface of the gas delivery pipe 701 is equipped with outlet nozzles 702 equidistantly arranged, and the bottom surface of the sealing top cover 101 and the surface of the gas delivery pipe 701 are equipped with overtime acoustic bubble detectors 703, and the sealing top c...

Embodiment 2

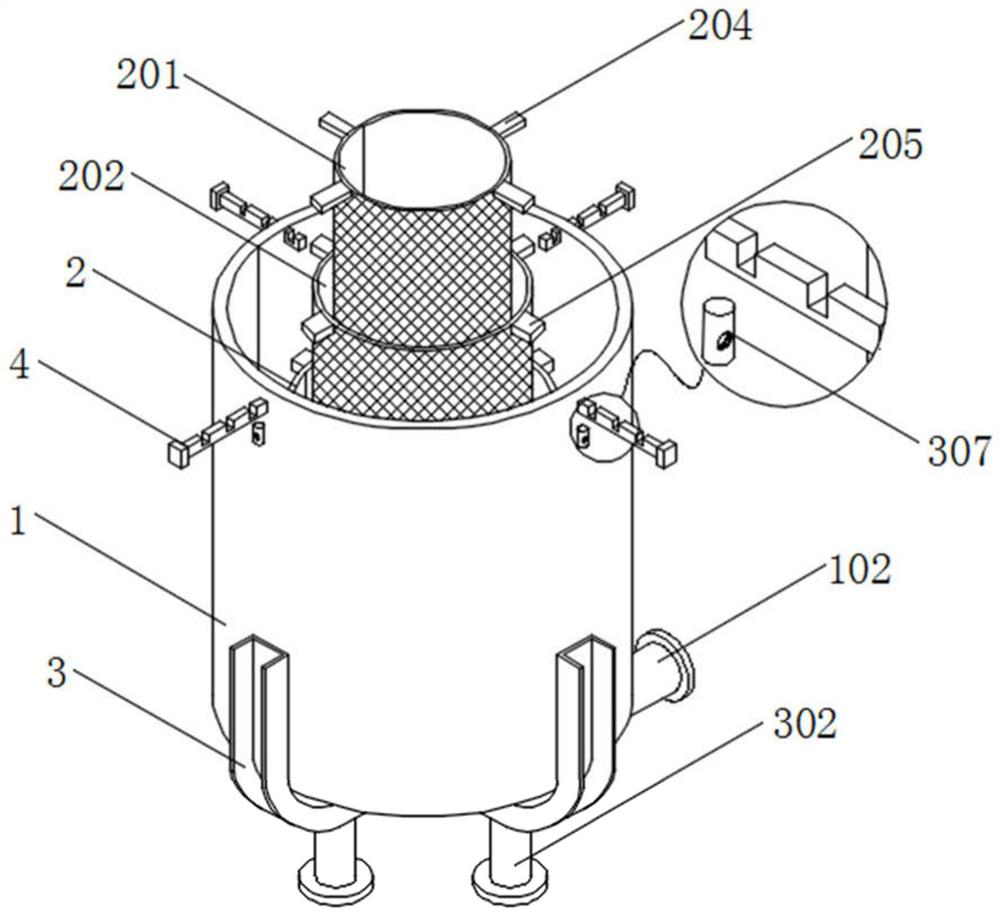

[0053] see figure 1 , figure 2 with Figure 4 , an embodiment provided by the present invention: a portable ceramic slurry filter for 3D printing, including a protective slide rail 3, L-shaped protective slide rails 3 are installed equidistantly on the surface of the filter cylinder 1, and the protective slide rail 3 There is a slider 301 slidingly connected inside the slider 301, a telescopic rod 304 is installed on the surface of the slider 301, a connecting screw 306 is installed through the tail end of the telescopic rod 304, a support rod 302 is installed on the bottom of the slider 301, and the tail end of the support rod 302 A protective pad 303 is connected, and a moving wheel 305 is installed on the bottom surface of the rear end of the protective slide rail 3 .

[0054] The surface of the filter cylinder 1 is equipped with positioning rods 307 equidistantly arranged, and the positioning rods 307 are located above the protective slide rail 3, and the inside of the ...

Embodiment 3

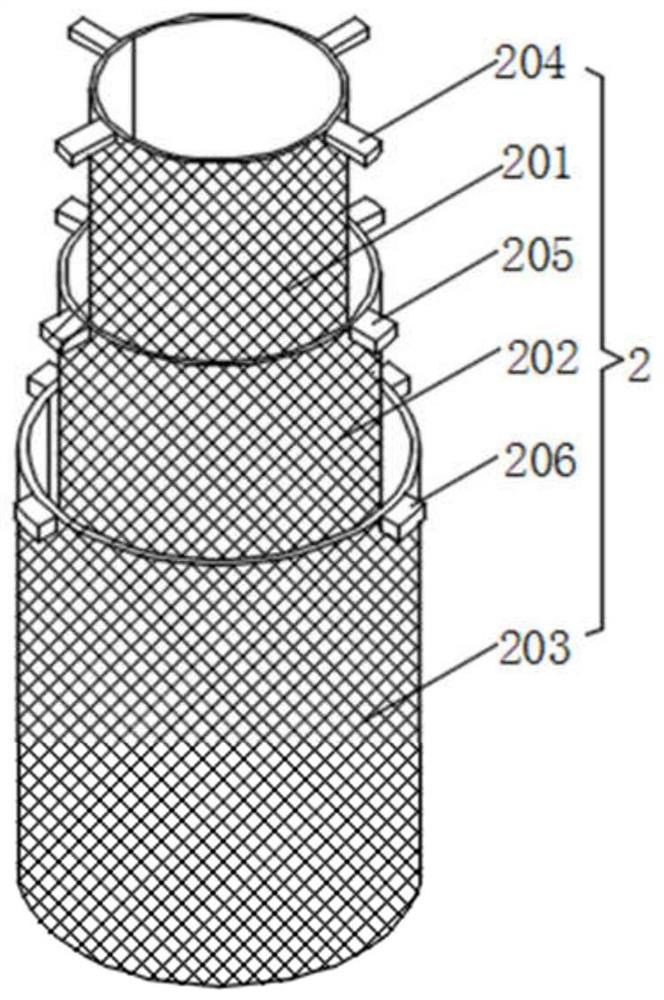

[0058] see figure 2 , image 3 with Figure 5 , an embodiment provided by the present invention: a portable ceramic slurry filter for 3D printing, including a screening structure 2, the inner wall of the filter cylinder 1 is penetrated with pull-out slide bars 4 arranged equidistantly, and the filter cylinder 1 A screening structure 2 is installed inside the screen by pulling the sliding bar 4. The screening structure 2 includes a No. 1 screen 201, a No. 2 screen 202, a No. 3 screen 203, a No. 205 and No. 3 fitting block 206, the top of the drawing slider 4 is provided with three sets of fitting grooves 402 equidistantly arranged, and the top of the drawing slider 4 is connected to a No. 1 fitting block through three sets of fitting grooves 402 204, No. 2 chimeric block 205 and No. 3 chimeric block 206, the surface of No. 1 chimeric block 204 is connected with No. 1 screen 201, the surface of No. 2 chimeric block 205 is connected with No. A No. 3 screen 203 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com