Boiler denitration integrated system

A denitrification and boiler technology, applied in the field of waste heat boiler flue gas denitrification, can solve the problems of increasing flow resistance, difficulty in changing flow direction, increased ammonia gas escape, etc., and achieve the effect of full reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

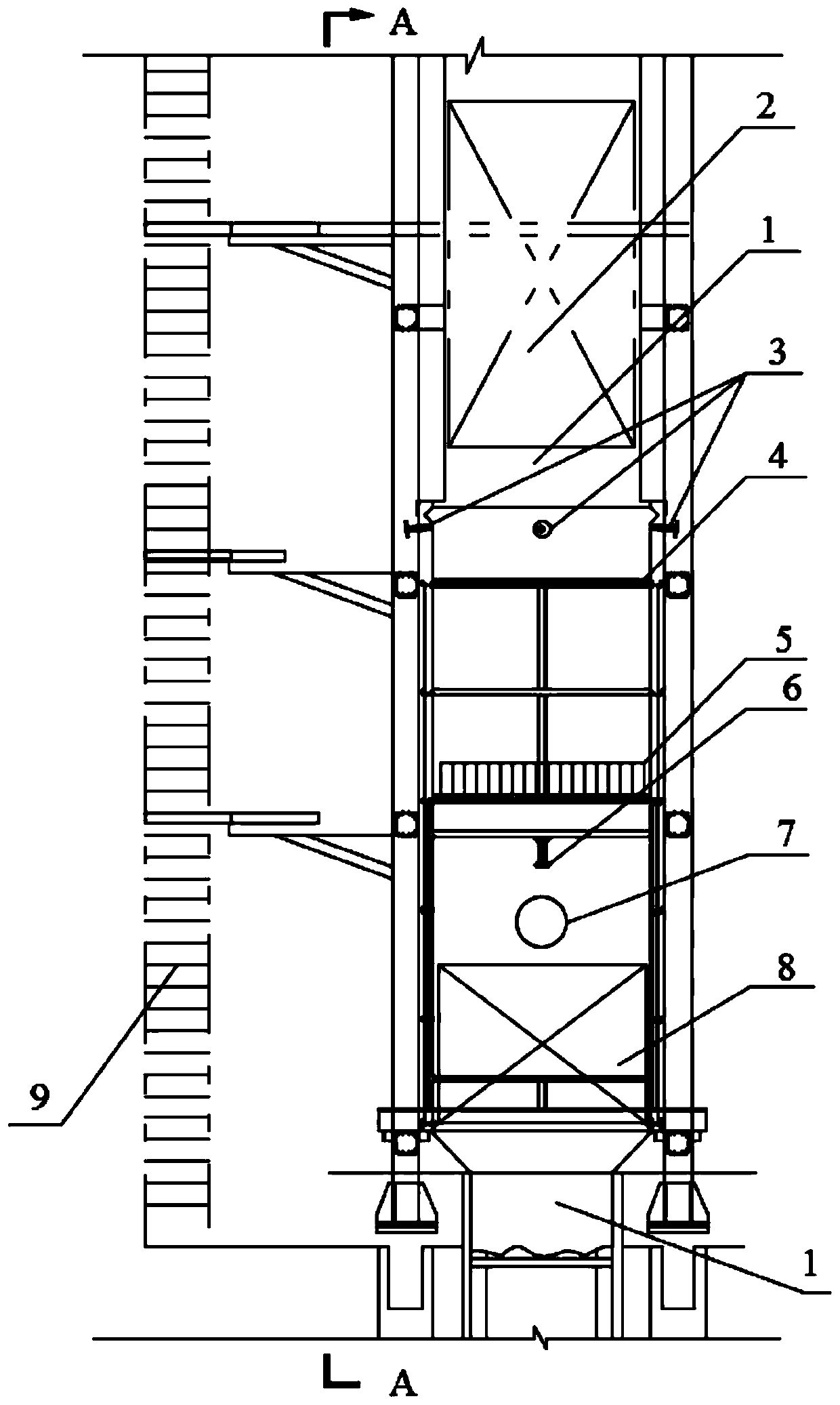

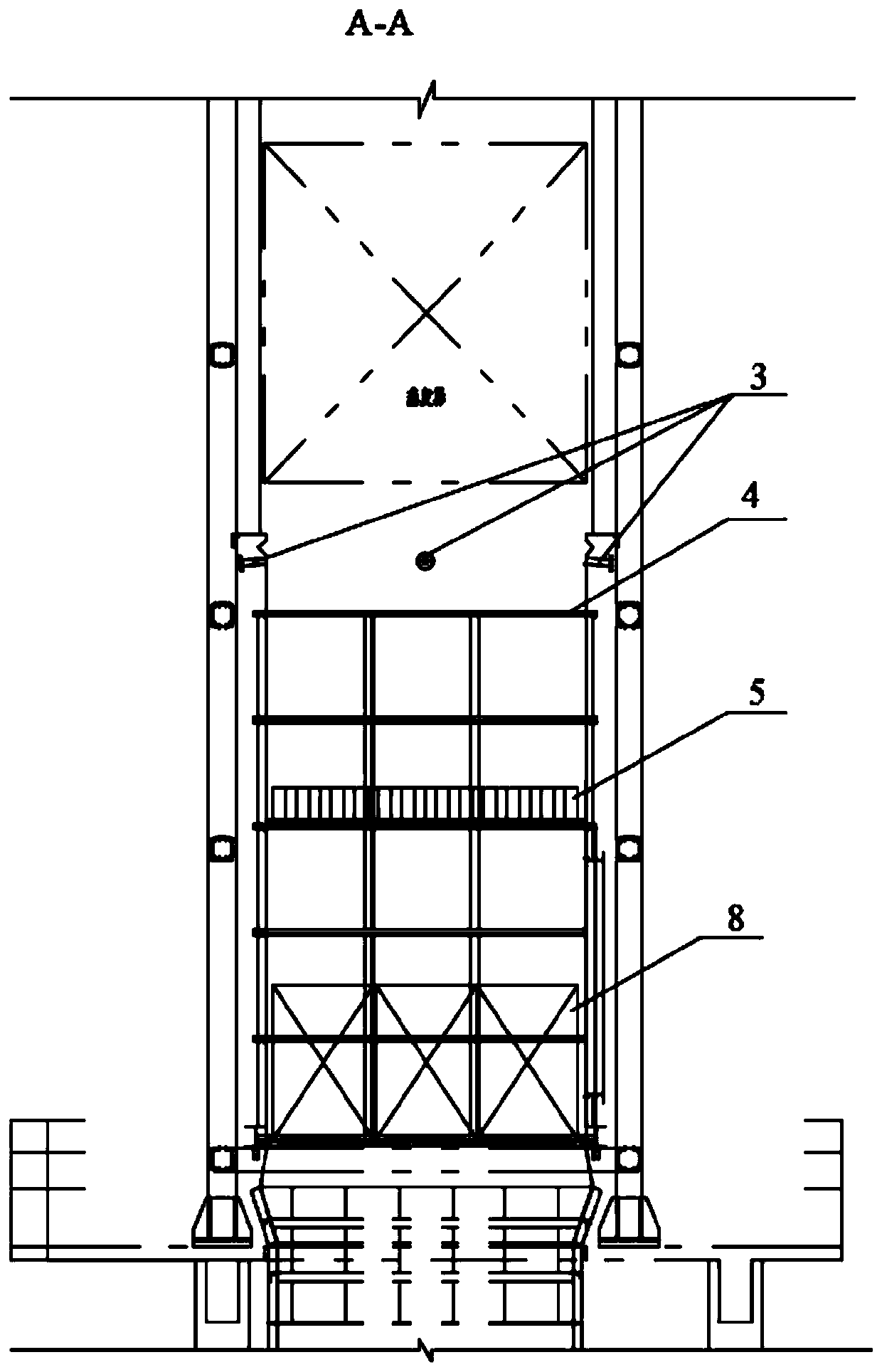

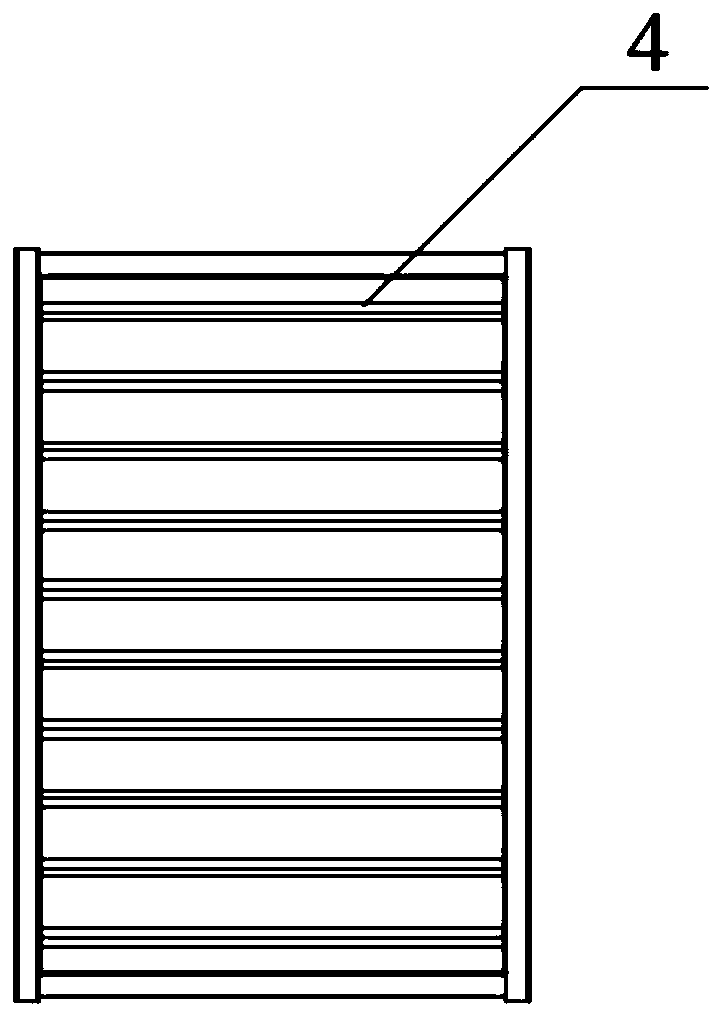

[0025] like Figure 1-4 The boiler denitration integrated system shown includes a flue 1, an ammonia water injector 3 is symmetrically arranged on the side wall of the flue 1, and a spoiler pipe 4, a rectifier is arranged from top to bottom below the ammonia water injector 3 in the flue 1. Grid 5 , catalyst hoisting track 6 , soot blower 7 and catalyst module 8 .

[0026] The ammonia water injector 3 is located below the evaporator 2 provided in the flue 1 .

[0027] The ammonia water injector 3 is arranged obliquely.

[0028] The inclination angle of the ammonia water injector 3 to the horizontal direction is 5-30°. In this embodiment, the inclination angle is 15°.

[0029] The number of ammonia water injectors 3 is at least four, and they are arranged symmetrically along the circumferential direction of the side wall of the flue 1 . In this embodiment, four ammonia water injectors 3 are used, which are respectively arranged on the four side walls of the flue.

[0030] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com