Insulating layer structure with flow guide function

An insulating layer and functional technology, applied to ships, bulk cargo, and some cabins in the hull, etc., can solve the problems of blind spots in liquid tank leakage detection, unclear leakage liquid diversion paths, and difficult coverage of diversion layers, etc. Achieve the effect of improving detection efficiency and accuracy, improving strength and service life, and improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The sizes, proportions, etc. shown in the drawings in this specification are only schematic and used to match the content described in the specification, and are not used to limit the implementation conditions of the present invention, and do not affect the effects of the present invention. The positional relationships such as "upper", "lower", "inner" and "outer" mentioned in this specification are only for convenience of description, and are not used to limit the scope of implementation of the present invention. Substantial changes in technical content are also regarded as the scope of implementation of the present invention.

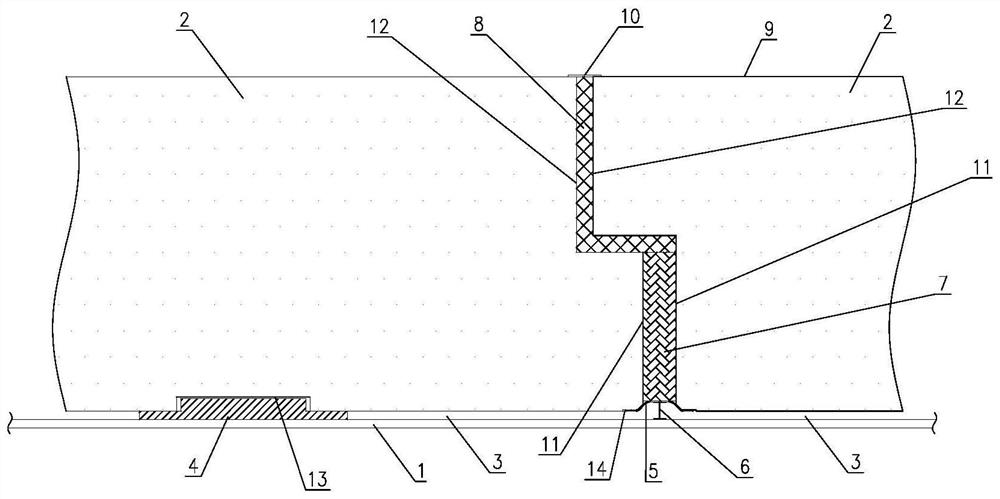

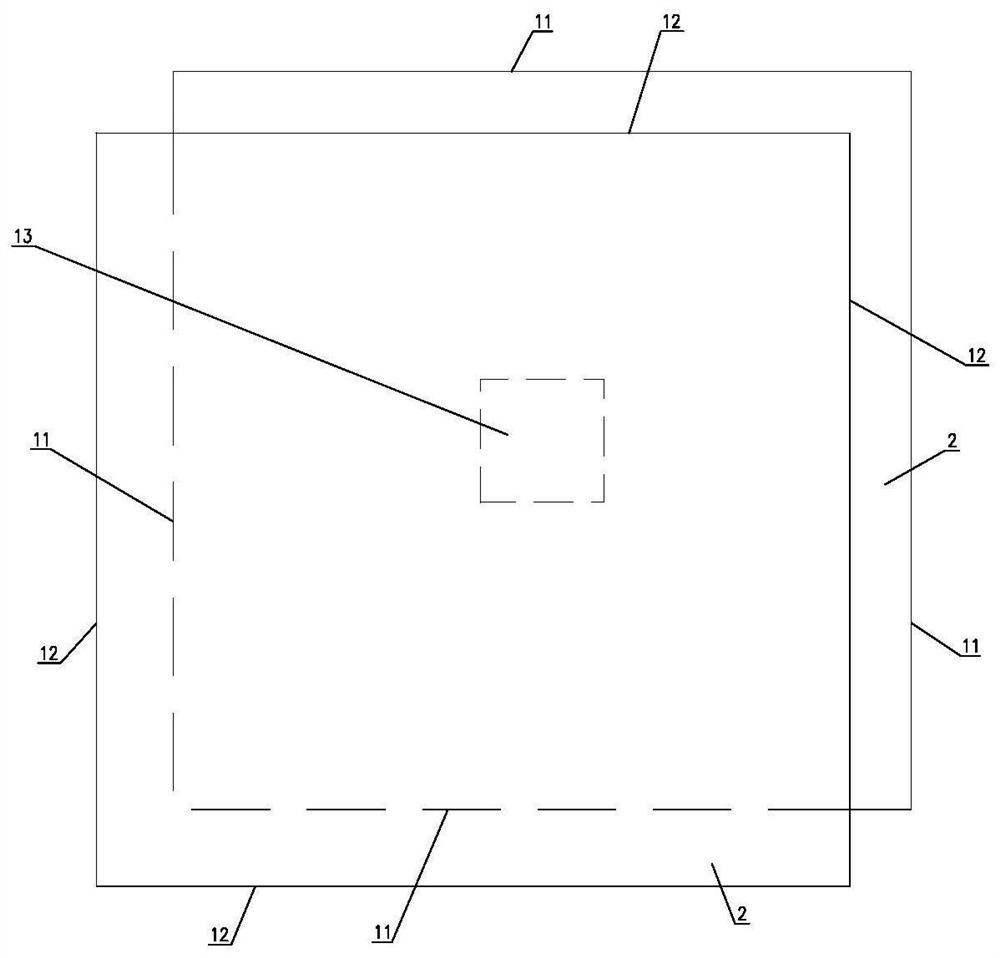

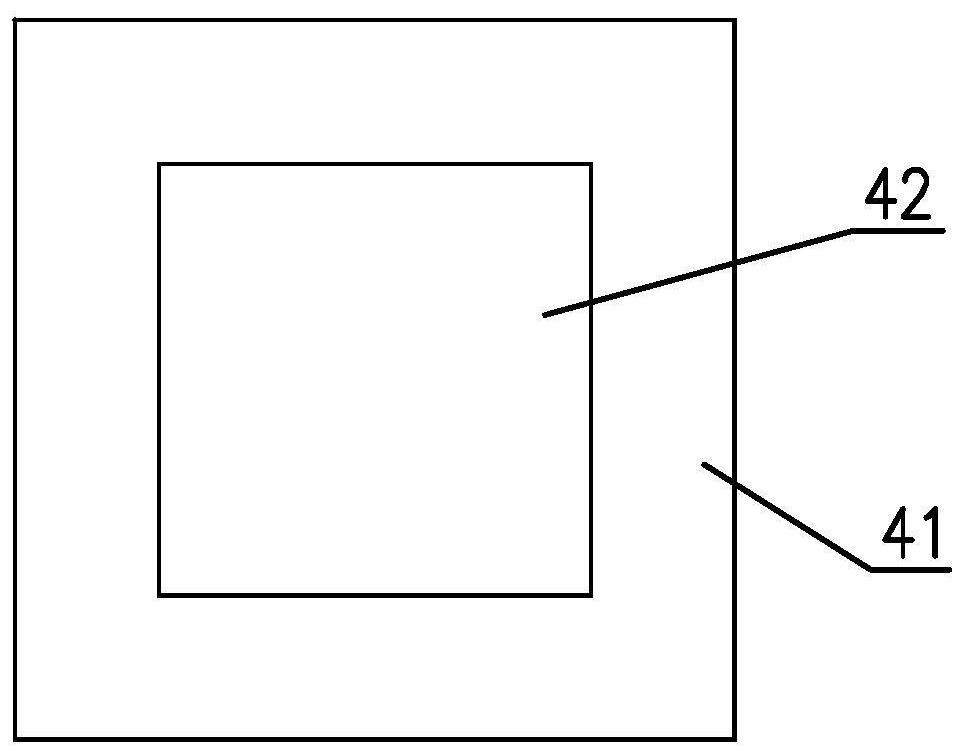

[0024] figure 1 As shown, the present invention provides an insulating layer structure with a conduction function, including a plurality of insulating blocks 2 fixed on the perimeter plate 1 of the liquid tank. The insulating block 2 is fixed by a fixing device 4 and forms a gap with the tank perimeter plate 1 . The innermost part of the gap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com