Double-layer diffusion and sawtooth tail edge integrated wheel rim driving propeller

A rim drive and propeller technology, which is applied to rotary propellers, propulsion components, ship propulsion, etc., can solve the problems of low space utilization, large vibration and noise, and reduced transmission efficiency, and achieves improved space utilization, Vibration and noise reduction, the effect of reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

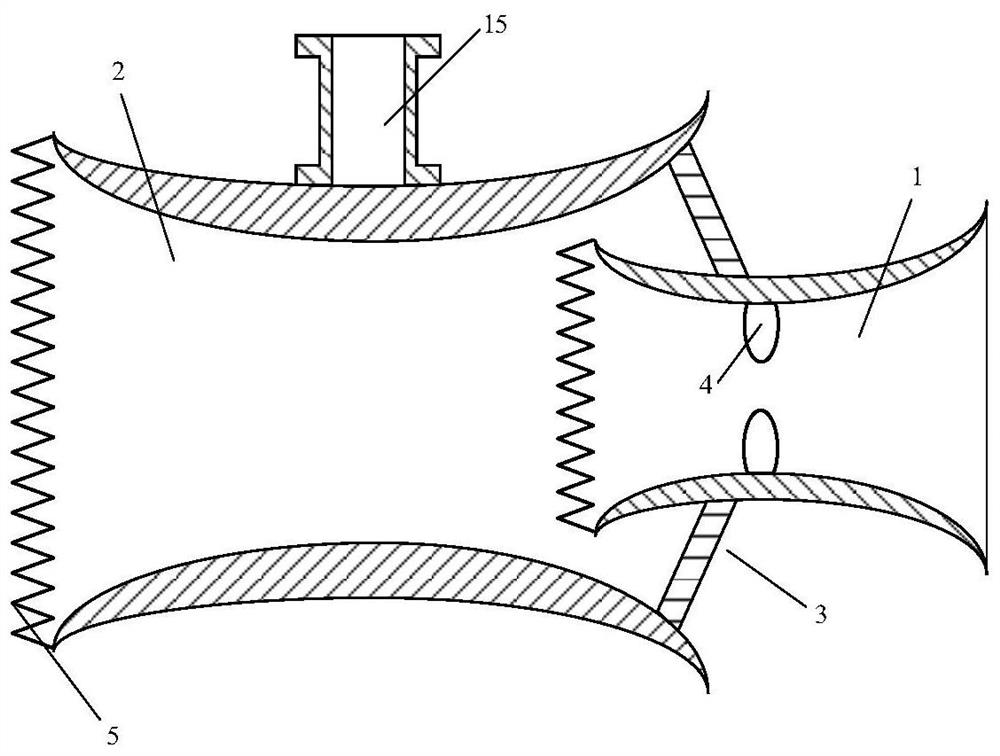

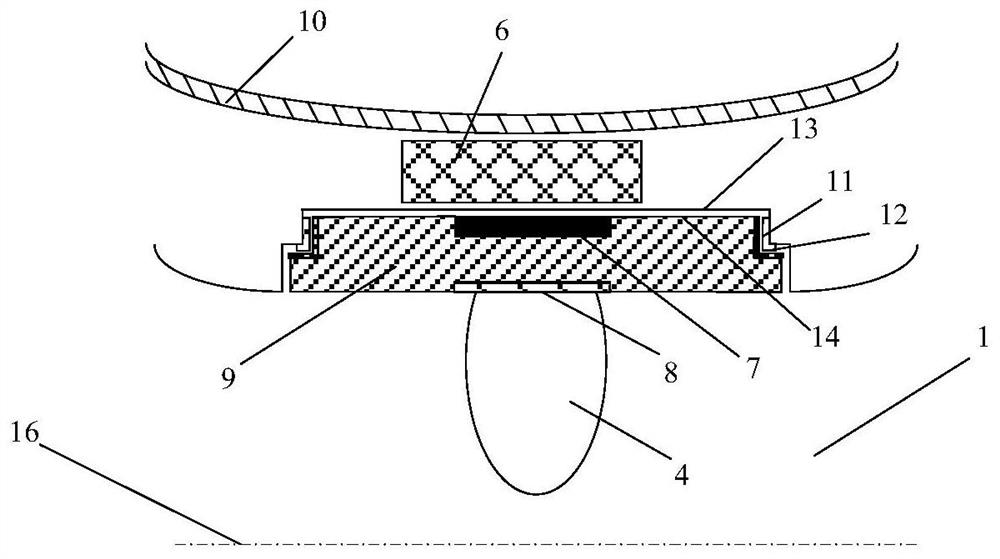

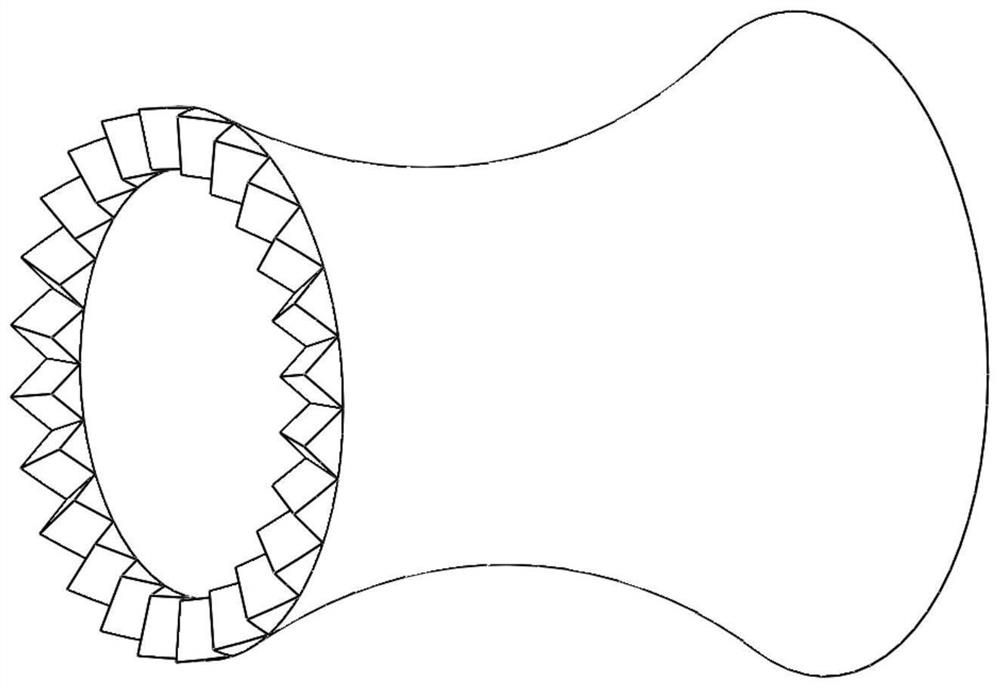

[0026] In order to better understand the structure and working principle of the present invention, it will be described below in conjunction with the accompanying drawings. Such as Figure 1-4 As shown, the double-diffusion and sawtooth trailing edge integrated rim-driven propeller provided by Embodiment 1 of the present invention includes a booster assembly, a stator winding 6, a rotor assembly, and a bearing assembly; the booster assembly includes a A double-layer diffusion structure composed of a first-stage multiplier 1 and a second-stage multiplier 2, the first-stage multiplier 1 and the second-stage multiplier 2 have the smallest cross-sectional area in the middle and large cross-sectional areas on both sides The tubular body structure can obviously speed up the flow rate of the water flowing into the propeller, forming a larger flow rate ratio. The tail ends of the conduits of the first-stage multiplier and the second-stage multiplier are all provided with a serrated tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com