High-temperature fused salt storage tank capable of freely stretching out and drawing back to release thermal stress

A high-temperature molten salt storage tank and heat release technology, applied in the field of high-temperature molten salt storage tanks, can solve the problems of large fillet weld cracking at the connection between the bottom plate and the wall plate, leakage of the molten salt storage tank, large friction coefficient, etc. The effect of large local stress, ensuring the safety of the storage tank and reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

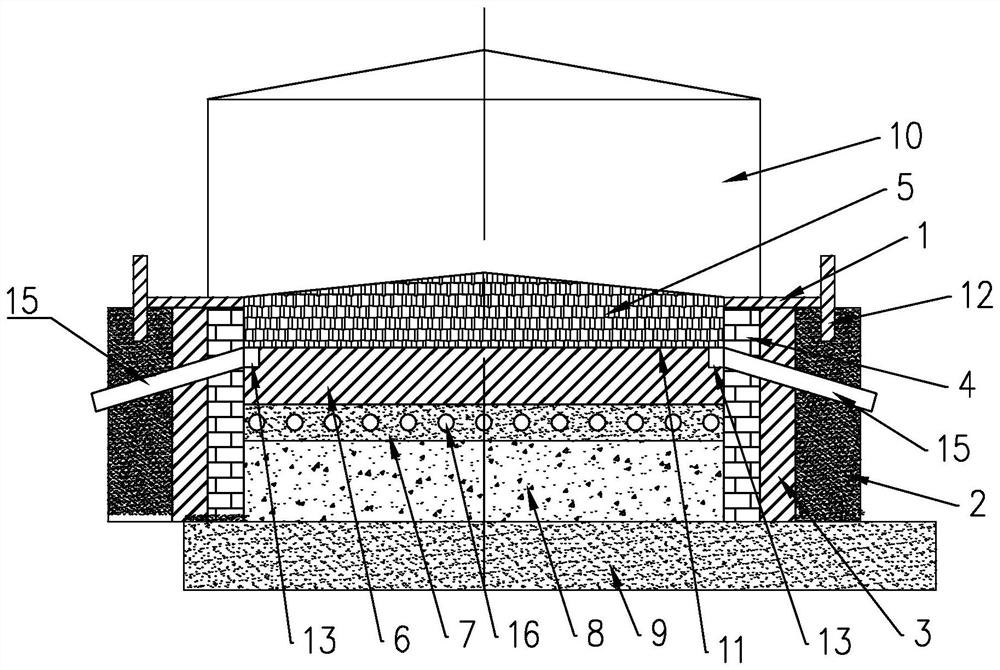

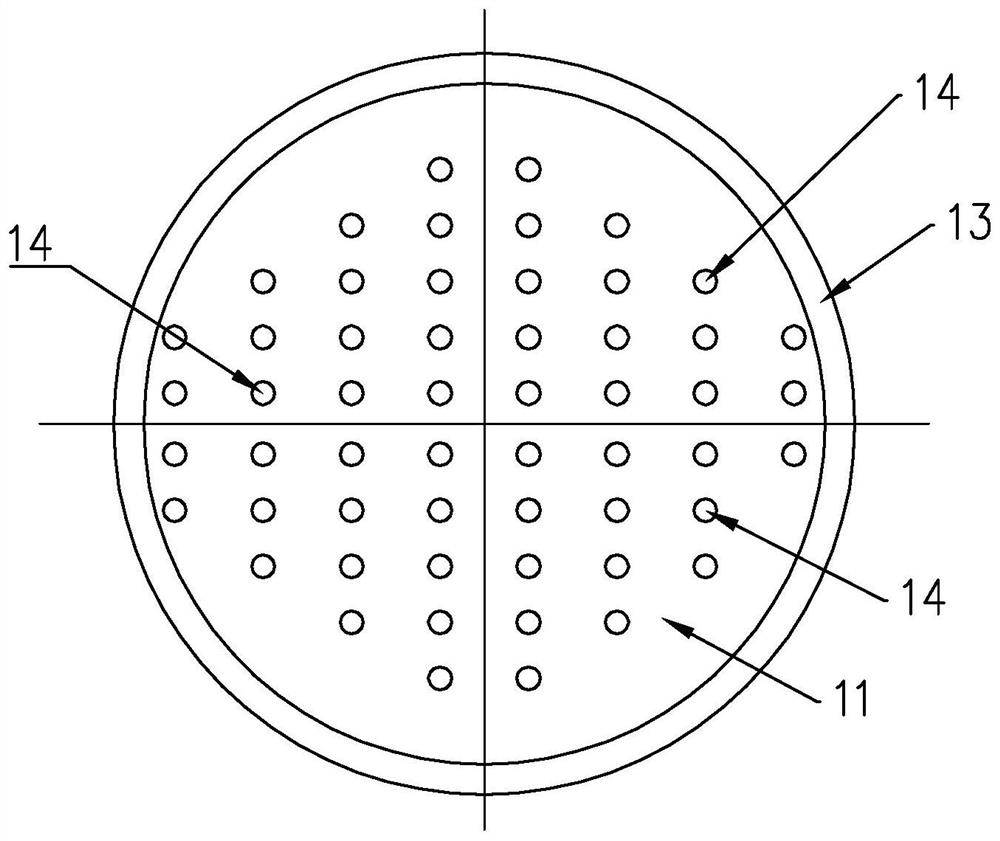

[0019] Such as figure 1 and figure 2 As shown, the high-temperature molten salt storage tank that can freely expand and contract to release thermal stress of the present invention includes a tank body 10, the bottom plate of the tank body 10 is conical with the cone angle facing upwards, and the middle part below the tank body 10 is provided with a sand-filled Sand cushion 5, the upper part of sand cushion 5 is a conical body with a cone angle upward, the bottom of sand cushion 5 is provided with a leak detection bottom plate 11, and a plurality of thermocouples 14 for temperature measurement are arranged on the leak detection bottom plate 11, A plurality of thermocouples 14 are respectively electrically connected to the electrical control device, and the outer edge of the leak detection bottom plate 11 is surrounded by a sump 13, and the lower part of the sump 13 is connected with the liquid inlet of the drain pipe 15, and the drain pipe 15 The liquid outlet is communicated...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap