Hollow harmonic joint module

A harmonic and joint technology, applied in the field of hollow harmonic joint modules, can solve the problems of high electronic hardware requirements, high production cost, large overall volume, etc., and achieve the effect of reducing production cost, simple assembly, and overall volume reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

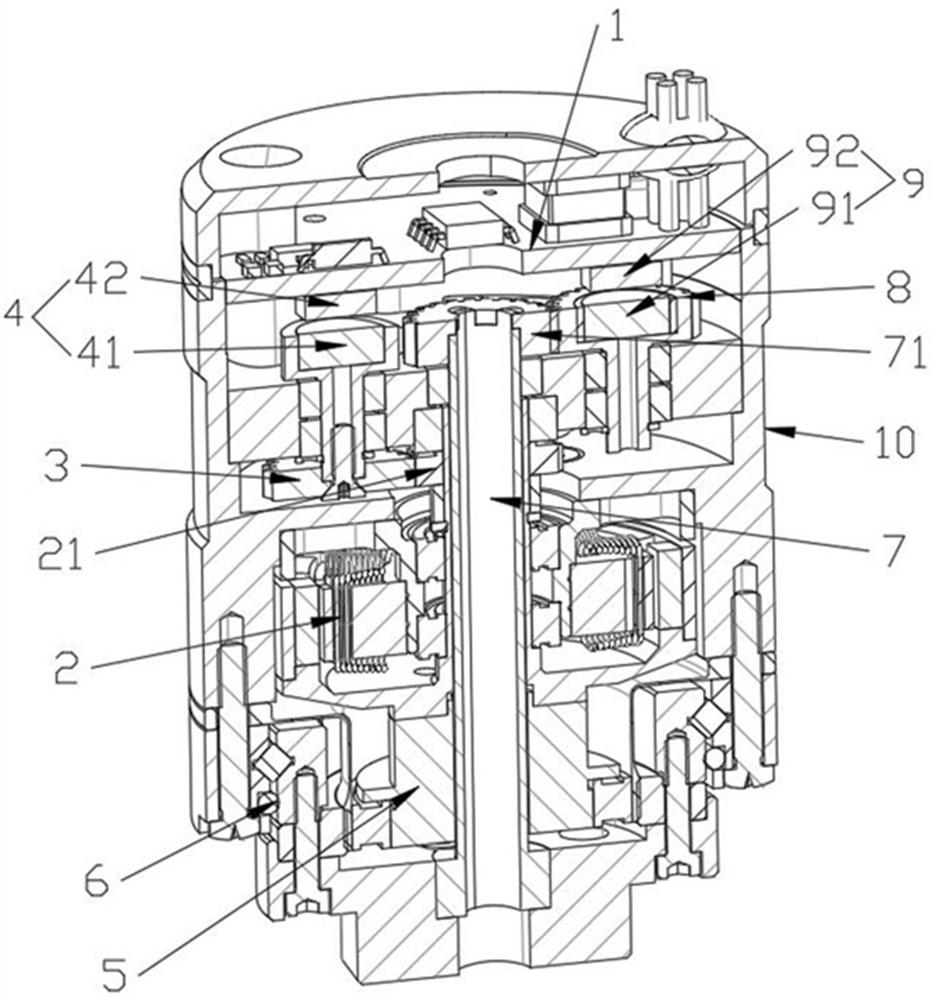

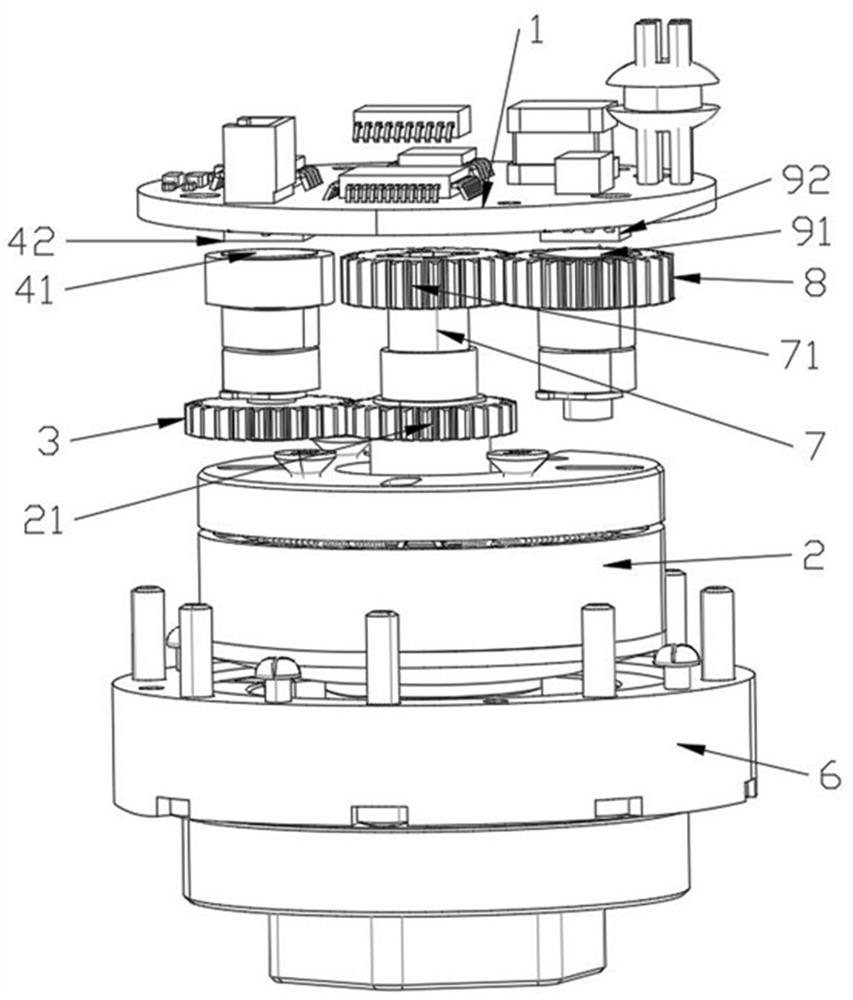

[0028] The invention will be further described below with reference to the accompanying drawings.

[0029] Such as Figure 1 to 5 One hollow harmonic joint module, including housing 10, control panel 1, motor 2, first gear set 3, first encoding assembly 4, cam 5, reducer 6, transmission shaft 7, second gear Group 8 and the second encoding assembly 9, in the present embodiment, the reducer 6 is a harmonic reducer 6, the housing 10 is cylindrical, the motor 2, the first gear set 3, the first encoding assembly 4, the drive shaft 7 The second gear group 8 and the second encoding assembly 9 are each disposed within the housing 10.

[0030] The motor 2 is an outer frame motor, the rotor of the motor 2 is a foreign turn design, low cost, small size, high heat transfer, and the prior art generally uselessless motor, high cost, large structure, large volume, large structure Small, the present invention is better than the prior art, and the heat dissipation performance is better, and there i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com