Surface colored paint spraying device for furniture wooden door processing

A spraying device and wooden door technology, applied in the direction of spraying devices, spray booths, etc., can solve the problems of inability to deal with harmful gases and uneven paint spraying, and achieve the effects of facilitating subsequent processing, avoiding air pollution, and ensuring health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

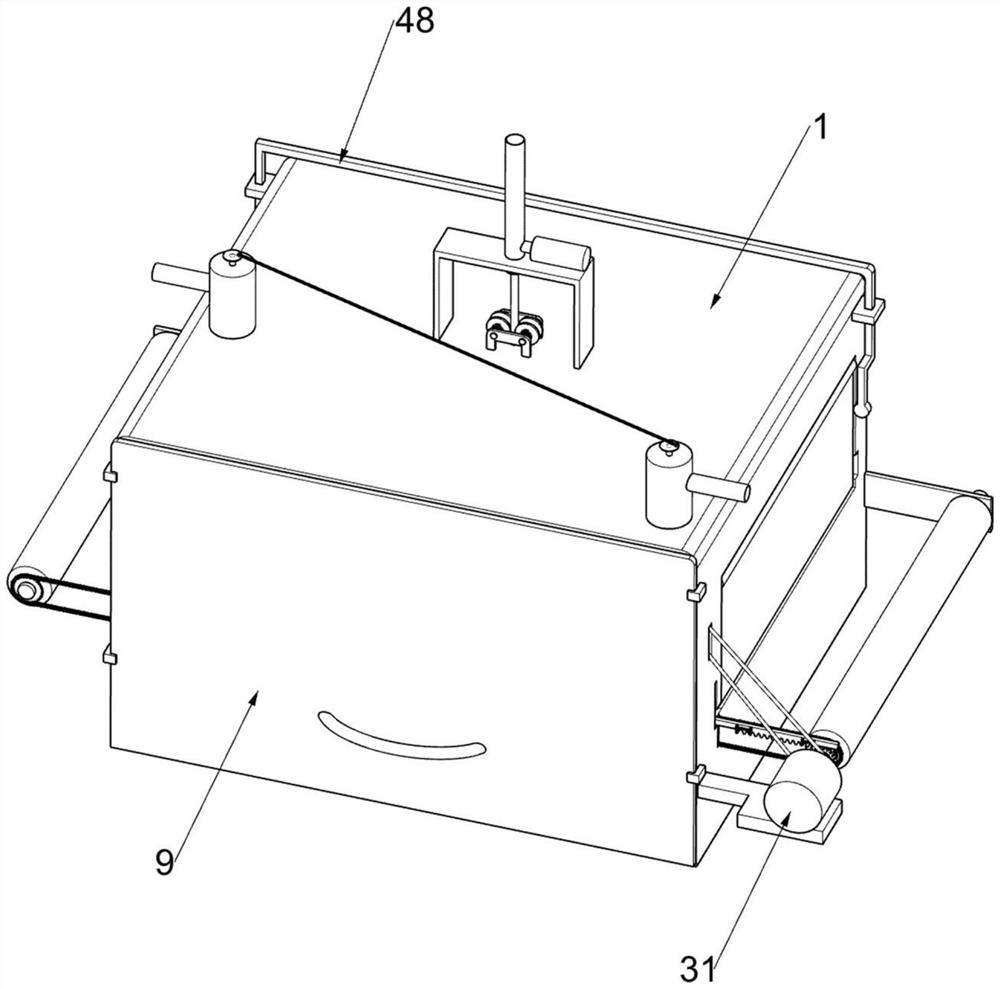

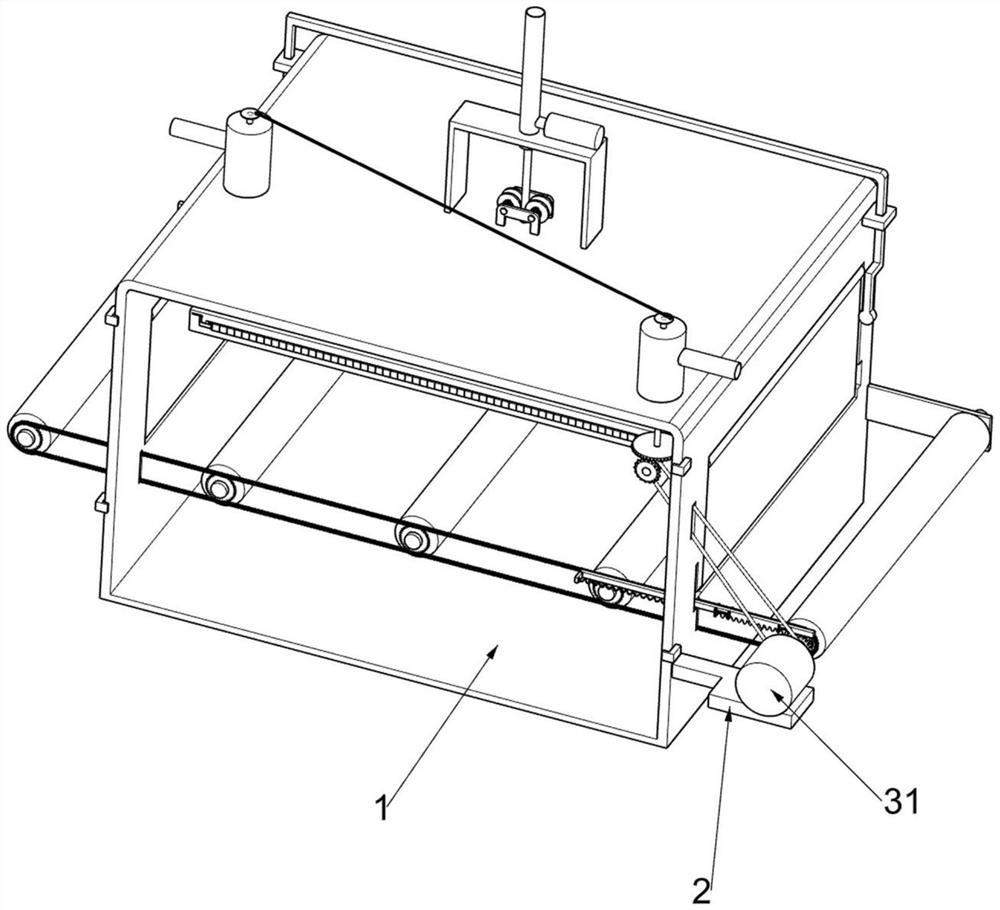

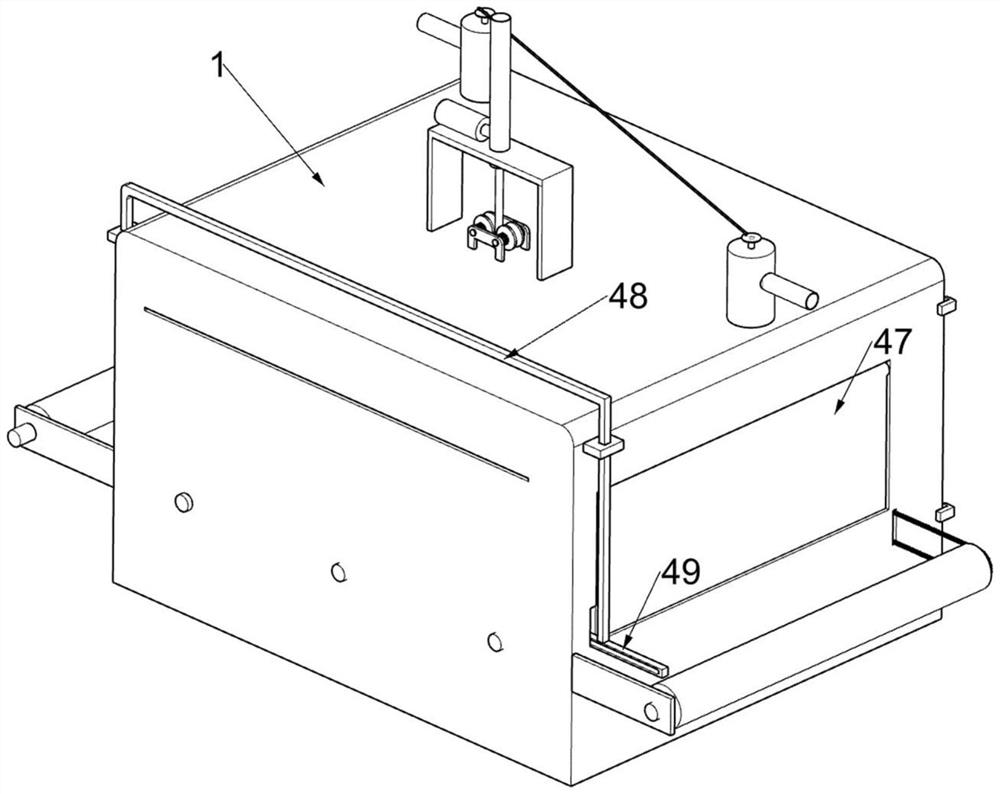

[0032] A kind of surface color paint spraying device for furniture wooden door processing, such as Figure 1-12As shown, it includes a spraying cabinet 1, a pallet 2, a conveying assembly 3 and an opening and closing assembly 4. A pallet 2 is fixedly welded on the right side of the outer wall of the spraying cabinet 1. The conveying assembly 3 and the opening and closing assembly 4 for timely closing the spraying cabinet 1 are arranged on the spraying cabinet 1 .

[0033] The conveying assembly 3 includes a servo motor 31, a power shaft 311, an overrunning clutch 32, a conveying roller 33, a conveying gear 1 34, a conveying gear 2 35 and a chain 36; 311 and the servo motor 31 on which the device rotates. The rear side of the spraying cabinet 1 is linearly distributed and rotationally connected with five power shafts 311. One end of the output shaft of the servo motor 31 is fixedly connected to one of the power shafts 311, and the three power shafts 311 are located in the spray...

Embodiment 2

[0038] On the basis of Example 1, such as Figure 6-9 As shown, a reciprocating assembly 5 is also included, and the reciprocating assembly 5 for evenly spraying paint is arranged on the spraying cabinet 1. The reciprocating assembly 5 includes an overrunning clutch two 51, a pulley one 52, a fixed guide plate 53, a two-way screw rod 54, a belt Wheel 2 55, belt 56, reciprocating groove plate 57 and moving block 58 are fixedly connected with overrunning clutch 2 51 on the power shaft 311 on the right side of spraying cabinet 1, and overrunning clutch 2 51 is fixedly connected with pulley 1 52, spraying cabinet 1. A fixed guide plate 53 is fixedly installed on the right side of the inner wall of the outer wall. The fixed guide plate 53 is L-shaped. The fixed guide plate 53 is rotatably connected with a two-way screw rod 54. A belt 56 is wound around the first wheel 52, and the first pulley 52 will drive the second pulley 55 and its upper device to reverse through the belt 56. Th...

Embodiment 3

[0043] On the basis of Example 2, such as Figure 10 As shown, also include shrink assembly 7, shrink assembly 7 is located on spraying cabinet 1, shrink assembly 7 includes fixed base 71, pneumatic tube 72, paint tank 73, connecting hose 74, fixed plate 75, movable wheel 76, A torsion spring 77 and a nozzle 78, a fixed seat 71 is fixedly installed above the outer wall of the spraying cabinet 1, a pneumatic tube 72 for conveying air pressure is fixedly connected on the fixed seat 71, and a paint tank 73 is fixedly installed at the bottom of the pneumatic tube 72, and the paint tank 73 is round Cylindrical, the paint tank 73 communicates with the pneumatic tube 72, the paint tank 73 is in contact with the fixing seat 71, and the connecting hose 74 for conveying the paint is fixedly connected under the pneumatic tube 72, and the material of the connecting hose 74 is good in tensile performance and durable. Bending rubber, the connecting hose 74 passes through the spraying cabine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com