A method for processing deviation curve between finishing strip steel stands based on machine vision

A machine vision and processing method technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve problems such as equipment jitter, shape control influence, influence operator judgment and adjustment, etc., to reduce installation errors, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0056] The invention provides a machine vision-based method for processing deviation curves between finish rolling strip steel stands.

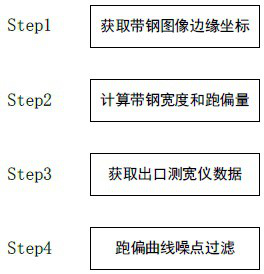

[0057] Such as figure 1 As shown, the method includes the following steps:

[0058] S1: Obtain the edge coordinates of the strip image:

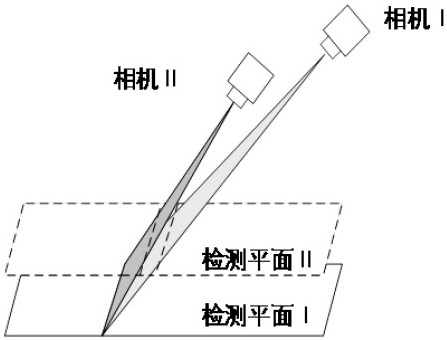

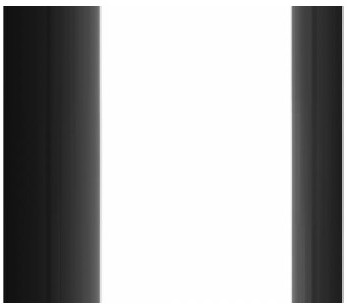

[0059] Use two cameras to collect the strip image at the same position at the same time, use the sub-pixel edge detection algorithm to detect the edge of the image, and obtain the left and right edge coordinates of the strip image at the time of acquisition;

[0060] S2: Calculate the width of the strip steel and the deviation relative to the rolling center line at the time of collection in S1;

[0061] S3: Obtain the set width data of the strip steel of the export width measuring i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com