Device and method for progressive impact hydraulic forming of multi-way pipe

A hydroforming and multi-pass tube technology, applied in the field of hydraulic bulging of metal tubes, can solve the problems of long pressurizing and depressurizing cycles, affecting forming accuracy, slow forming speed, etc. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

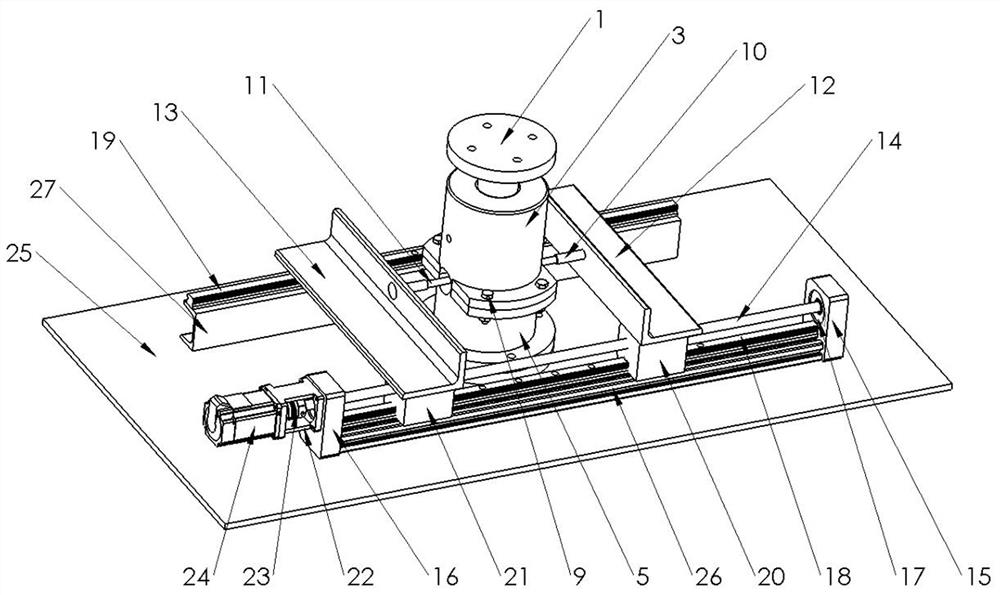

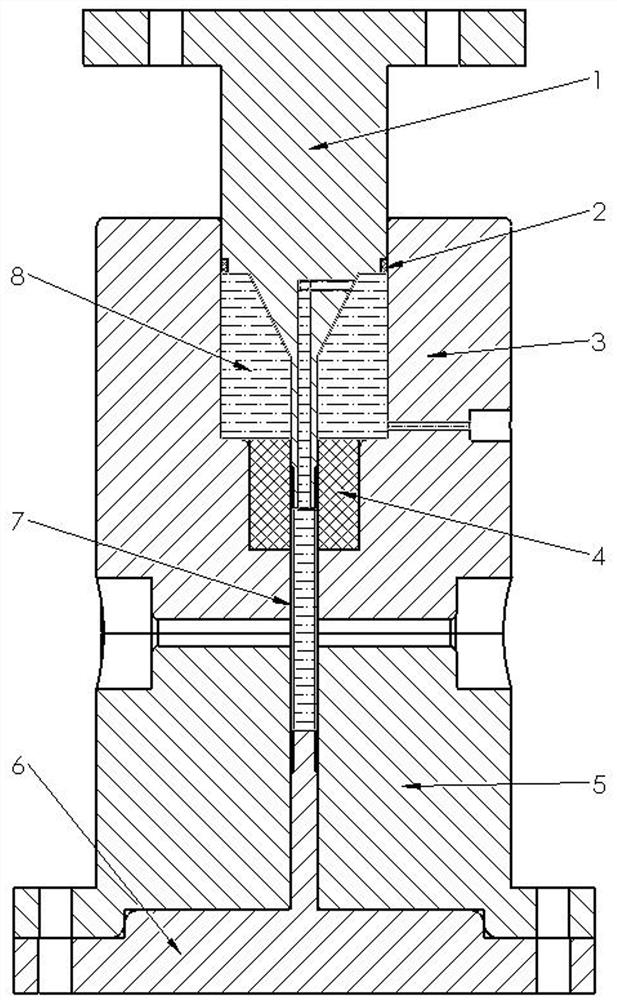

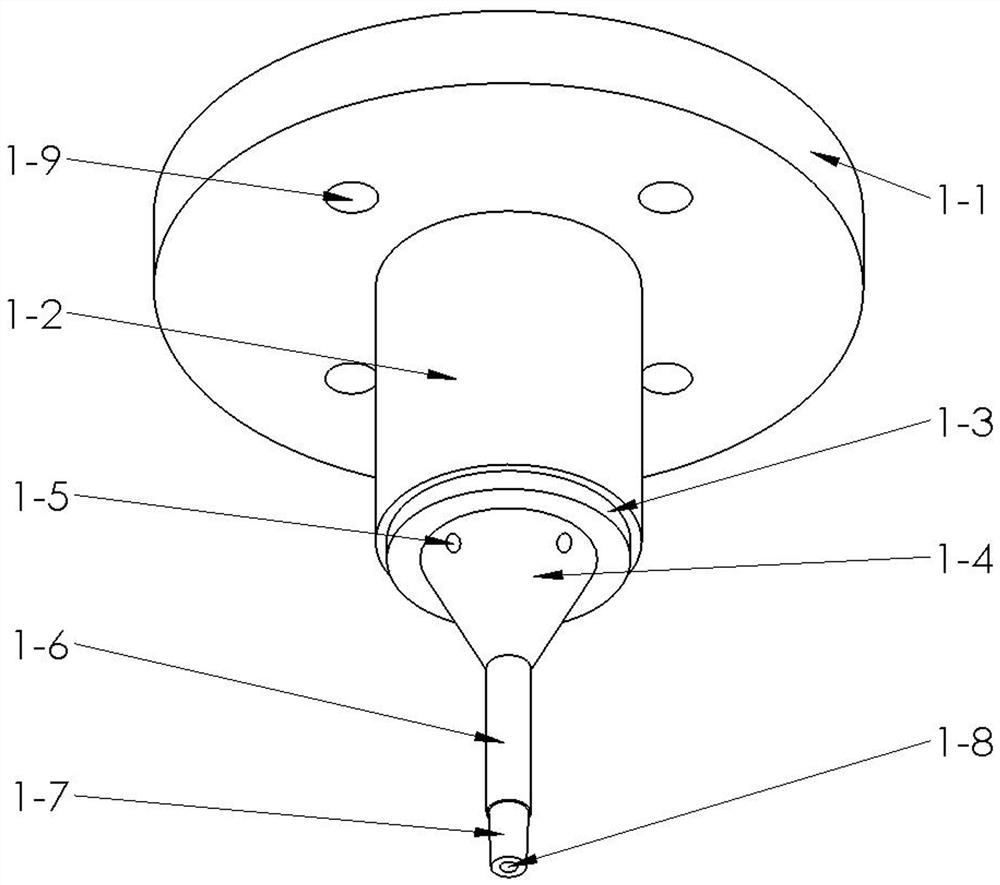

[0037] Refer figure 1 , figure 2 A method for progressive multi-way shock tube hydroforming apparatus includes a base 25, the base 25 is provided with a first bracket 26 and second bracket 27 arranged two parallel, a first bracket 26 and second bracket 27 respectively a first rail 18 and second rails 19, 18 on the first rail and the second guide rail 19 has a symmetrical slidable on a first guide rail 18 second guide rail 19 and the first and second sliders 20 slide 21, one end of the first bracket 26 is provided with a first bearing housing 15, the other end is provided with a second bearing housing 16, bearing housing 16 inside the first and second bearing housing 15 is provided with a pair of bearings 17, 16 and the bearing seat motor mount 22 is connected, the motor 24 is provided on the motor base 22, the screw through the bearing 17 provided between the first bearing housing 15 and a second 14 bearing seat 16, the screw 14 and the motor shaft 22 is connected by a coupling , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com