Rapid storage and circulation warehouse for slotless side formworks

A technology of circulation library and mold library, which is applied in ceramic molding workshops, auxiliary molding equipment, ceramic molding machines, etc., and can solve problems such as the long position of manipulators, the inability to meet the tempo of production operations, and the restriction of production efficiency of automatic lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

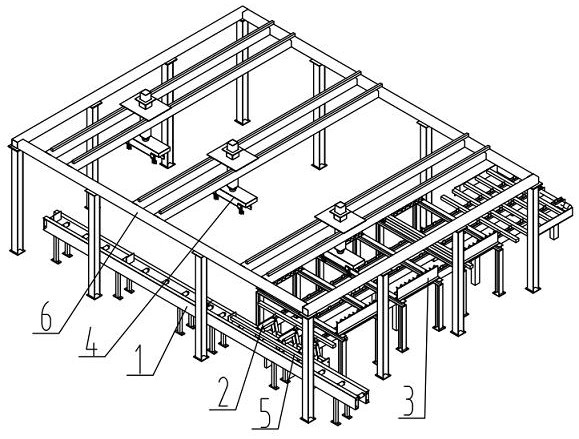

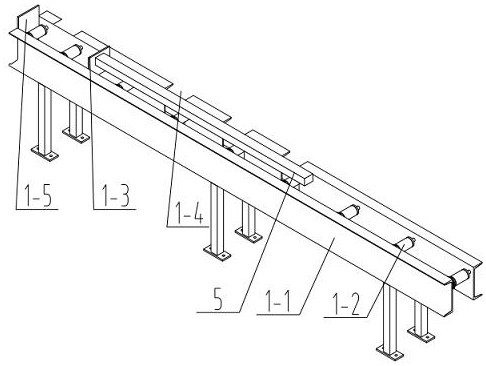

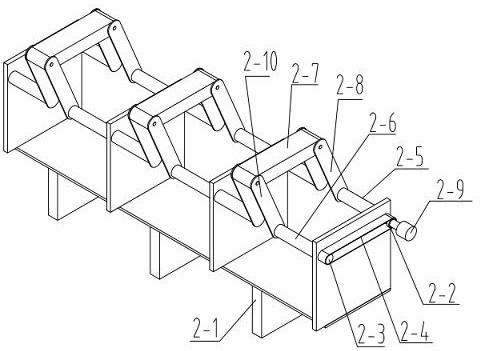

[0021] The specific embodiment of the present invention is described below in conjunction with accompanying drawing: comprise going out, storage manipulator 4, manipulator frame 6, side mold storehouse and side mold conveying roller table 1. Below the manipulator frame 6, there are 3 groups of dynamic and static combined side mold warehouses 3, and on the manipulator frame 6 above each group of dynamic and static combined side mold warehouses 3, a manipulator 4 for going out and entering the warehouse is installed; The roller table 1 is arranged at the end of the dynamic and static combined side form library 3, and a side form lateral movement device 2 is installed between the side form conveying roller table 1 and each group of dynamic and static combined side form library 3; The dynamic side form storehouse 3-1 of the dynamic and static combined side form storehouse 3 is located below, and the static side form storehouse 3-2 spans above the dynamic side form storehouse 3-1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com