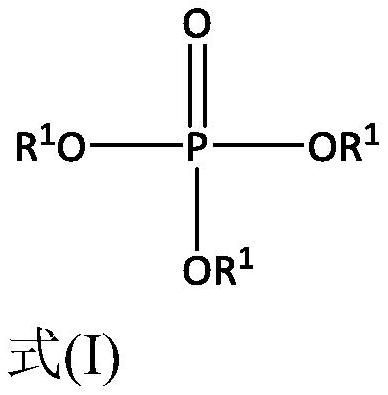

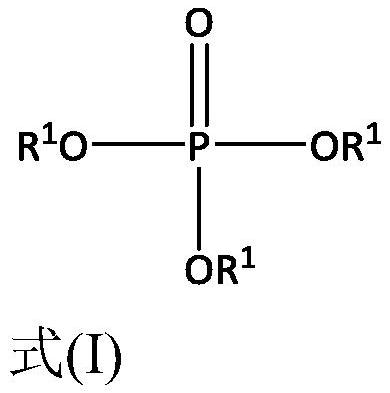

Use of long-chain phosphoric acid esters in aqueous polyurethane dispersions

A technology of polyurethane dispersion and long-chain phosphate, which is applied in polyurea/polyurethane coatings, phosphorus oxides, layered products, etc., and can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

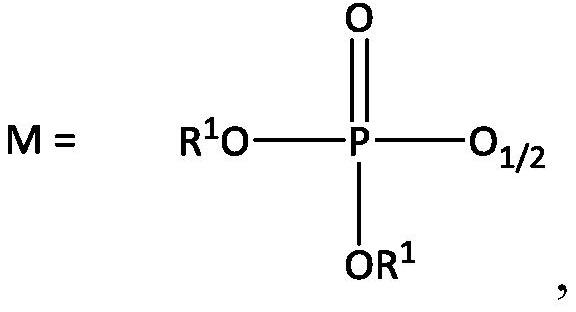

Method used

Image

Examples

Embodiment 1

[0094] Embodiment 1: the synthesis of stearyl phosphate that the degree of esterification is 1.5:

[0095] While stirring and introducing N 2 While heating stearyl alcohol (≥95%, 212.8g, 0.787mol) to 70°C, add P in small batches 4 o 10 (37.23 g, 0.131 mol), so that the temperature of the reaction mixture does not rise above 80 °C. at P 4 o 10 After the addition of , after the introduction of N 2 The reaction mixture was stirred at 80° C. for 3 hours until the acid value was constant. After decanting and cooling, a colorless solid with an acid value of 164 mgKOH / g was obtained.

Embodiment 2

[0096] Embodiment 2: the synthesis of stearyl phosphate that the degree of esterification is 1.8:

[0097] While stirring and introducing N 2 While heating stearyl alcohol (≥95%, 174.7g, 0.646mol) to 70°C, add P in small batches 4 o 10 (25.45 g, 0.0896 mol), so that the temperature of the reaction mixture does not rise above 80 °C. at P 4 o 10 After the addition of , after the introduction of N 2 The reaction mixture was stirred at 80° C. for 3 hours until the acid value was constant. After decanting and cooling, a colorless solid with an acid number of 139 mg KOH / g is obtained.

Embodiment 3

[0098] Embodiment 3: the synthesis of stearyl phosphate that the degree of esterification is 2.2:

[0099] While stirring and introducing N 2 While heating stearyl alcohol (≥95%, 178.7g, 0.661mol) to 70°C, add P in small batches 4 o 10 (21.31 g, 0.0751 mol) so that the temperature of the reaction mixture does not rise above 80°C. at P 4 o 10 After the addition of , after the introduction of N 2 The reaction mixture was stirred at 80° C. for 3 hours until the acid value was constant. After decanting and cooling, a colorless solid with an acid number of 127 mg KOH / g is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com