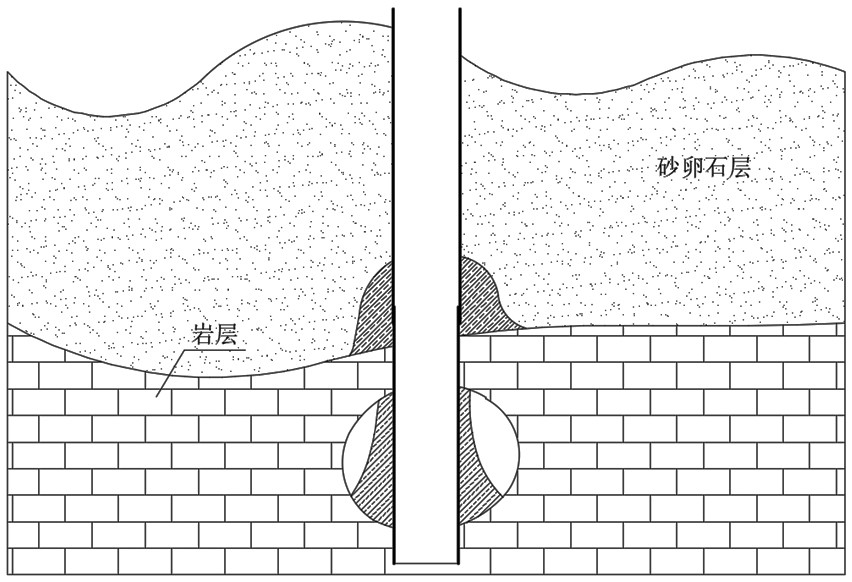

Steel sleeve wall protecting device and construction method of cast-in-place pile in sandy gravel rock area

A construction method and technology of steel sleeves, applied in drilling equipment and methods, casings, sheet pile walls, etc., can solve problems such as pressure imbalance, reduce loss, ensure verticality, and increase vertical bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

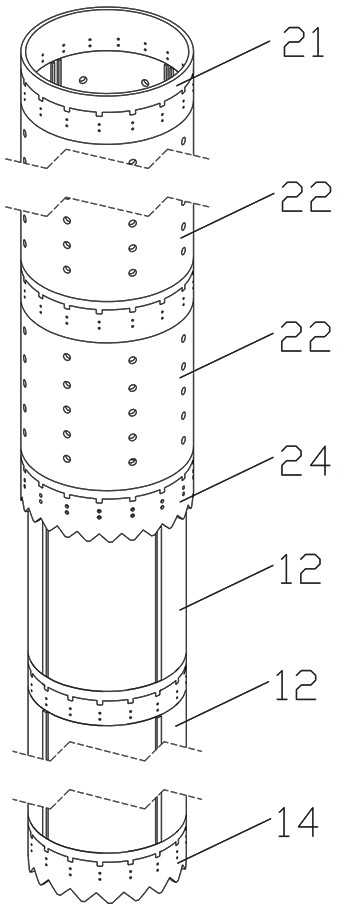

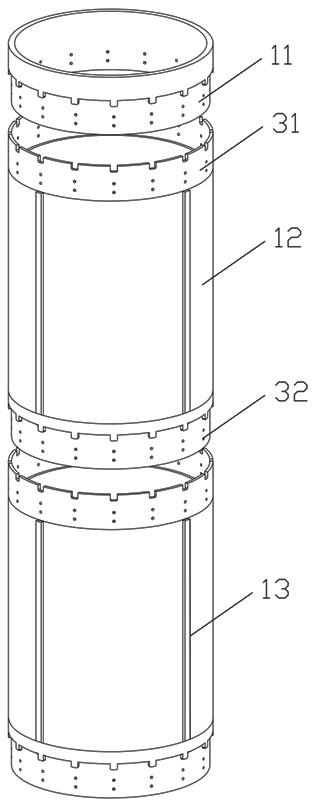

[0046] See figure 1 , a steel sleeve wall protection device, comprising an outer sleeve mechanism, an inner sleeve mechanism, an inner sleeve connector 11 and an outer sleeve connector 21, the outer sleeve mechanism includes two or more outer steel sleeves fixedly connected in sequence Sleeve 22, the inner sleeve mechanism includes more than two internal steel sleeves 12 fixedly connected in sequence;

[0047] The outer wall of each section of the inner steel sleeve 12 is evenly arranged with an axial strip-shaped plate 13, and the inner wall of each section of the outer steel sleeve 22 is evenly equipped with an axial long groove 23, and the strip-shaped plate 13 can be slidably fitted. Set in the long groove 23, so that the inner sleeve mechanism coaxially slides in the outer steel sleeve mechanism;

[0048] Holes are uniformly opened on the wall of each outer steel sleeve 22;

[0049] The bottom end of the outer steel sleeve 22 located at the bottom of the outer sleeve me...

Embodiment 2

[0058] The present invention also includes a construction method for cast-in-situ piles in sand and pebble rock areas. The construction method adopts the above-mentioned steel sleeve wall protection device. The outer steel sleeve 22 is rolled by Q345 steel plate and processed by cast steel hot rolling. The inner diameter of the sleeve 22 is 10-20 cm larger than the pile diameter. When the pile diameter is 160 cm, the inner diameter of the outer steel sleeve 22 is 173 cm, and the outer diameter is 175 cm.

[0059] The inner steel sleeve 12 is coiled with Q345 steel plate and hot-rolled by cast steel. The inner diameter of the inner steel sleeve 12 is 5-10 cm larger than the pile diameter. When the pile diameter is 160 cm, the inner diameter of the inner steel sleeve 12 is 165 cm. , the outer diameter of the cylinder is 168cm;

[0060] The length of each outer steel sleeve 22 or inner steel sleeve 12 is 3 m.

[0061] Described construction method specifically comprises the foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com