Steel frame-support connecting joint based on thickness design of main connecting plate

A technology for connecting nodes and main connections, which is applied in the direction of architecture and building construction, etc. It can solve the problems of heavy welding workload and complicated fire prevention treatment, and achieve the effect of reducing construction difficulty, welding work difficulty and coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

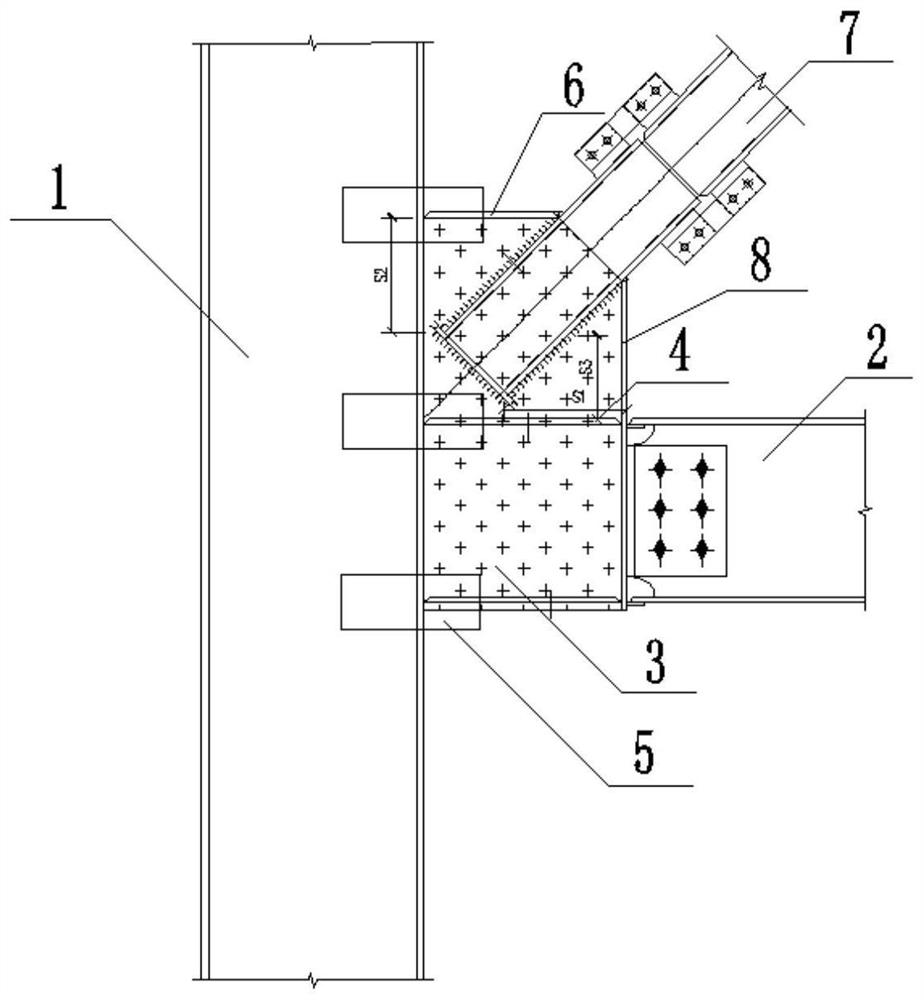

Embodiment 1

[0048] The joints include wide steel column 1, beam 2, main connecting plate 3, horizontal stiffener 4, pasting plate 5 and support section 7, the connection between wide steel column 1 and beam 2, and the end of beam 2 passes through main connecting plate 3 and wide The outer wall of the steel column 1 is connected; wherein, the horizontal height of the bottom of the beam is aligned with the bottom end of the main connecting plate.

[0049] Such as Figure 1-Figure 5 As shown, the main connecting plate 3 is vertically arranged, one end is welded and fixed to the outer wall of the wide steel column 1, and the other end is welded and fixed to the end of the beam 2, and the web of the main connecting plate 3 and the beam 2 is located on the same vertical plane; Horizontal stiffeners 4 are welded on both sides of the upper and lower ends of the main connecting plate 3 where the upper and lower flanges of the beam 2 are at the same height, that is, on both sides of the main connec...

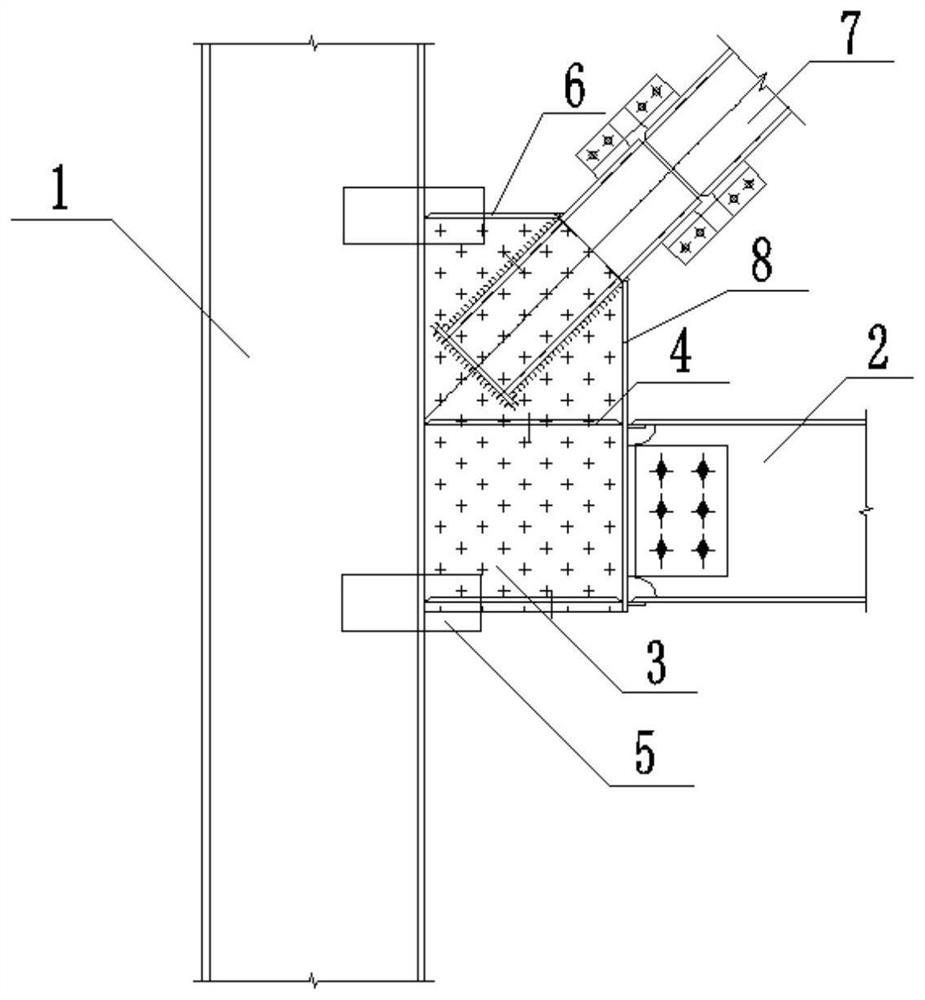

Embodiment 2

[0058] Such as figure 2 As shown, remove the two sticking plates 5 welded to the horizontal stiffener 4 in the middle of the main connecting plate 3 in Embodiment 1 of the steel frame-supporting connection node of the present invention.

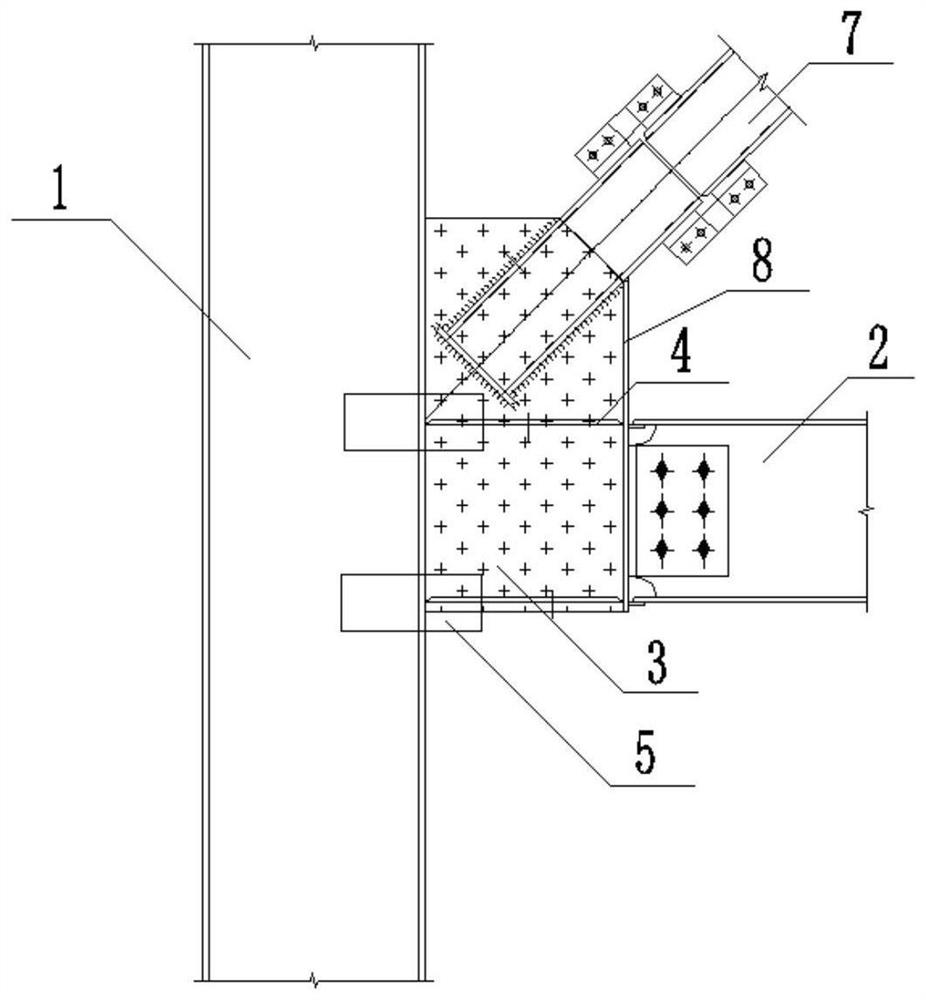

Embodiment 3

[0060] Such as image 3 As shown, the cover plate 6 welded to the upper section of the main connecting plate 3 and the two subplates 5 welded to the side of the cover plate 6 in Embodiment 1 of the steel frame-support connection node of the present invention are removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com